Annular wettability gradient copper net and production method thereof

A wetting and copper mesh technology, which is applied in the field of annular wetting gradient copper mesh and its preparation, can solve the problems of low water collection efficiency and high cost, and achieve the effects of high water collection efficiency, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

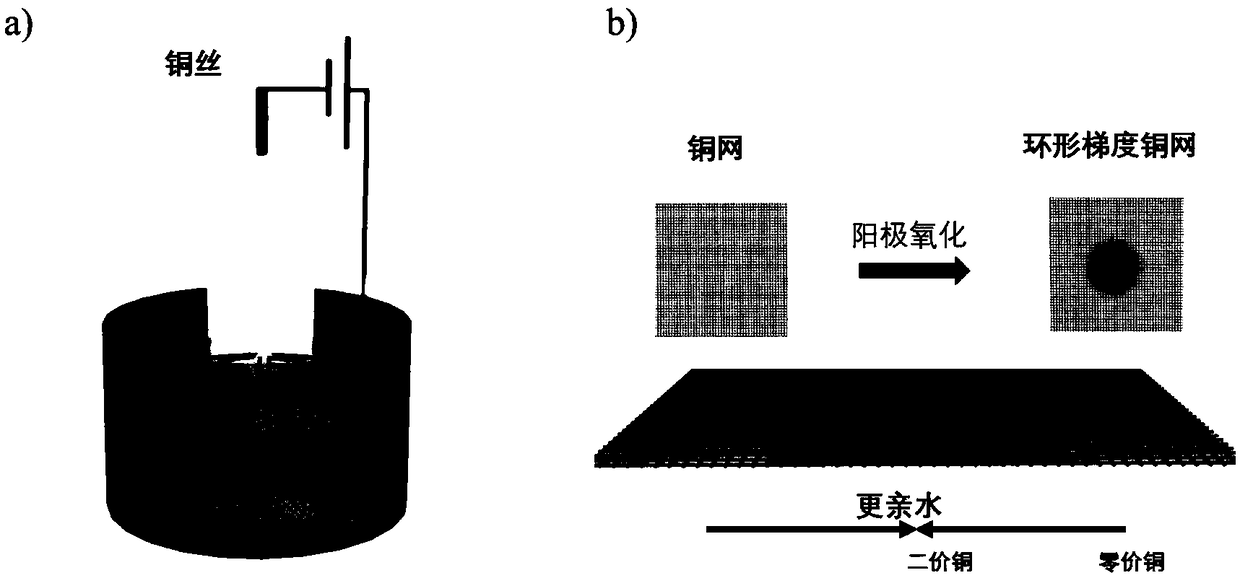

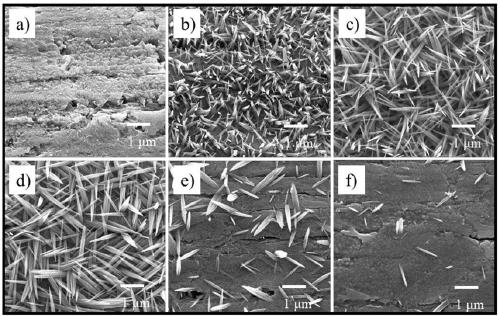

[0024] In the preparation method of the annular wettable gradient copper mesh provided by the present invention, the copper mesh is immersed in the electrolyte by an anodic oxidation method, and rapidly oxidized under certain conditions to form an annular gradient electric field to obtain the annular wettable gradient copper mesh. The experimental device for anodizing such as figure 1 As shown in a, the schematic diagram of the experimental process is shown in figure 1 As shown in b, during the experiment, current 1>current 2>current 3, so the oxidation effect on different positions of the copper mesh is different. The divalent copper in the center has good hydrophilicity, and the farther away from the center, the worse the hydrophilicity. A copper mesh with a circular wettability gradient is formed.

[0025] The prepared annular wettable gradient copper mesh has a beetle-like hydrophilic and hydrophobic lattice structure, which can quickly capture the moisture in the mist, q...

Embodiment 1

[0027] The preparation method of annular wettable gradient copper mesh, the specific steps are as follows:

[0028] (1) Put the 180-mesh copper net of 16cm×16cm into 0.1% nitric acid, acetone, and ethanol solution for 15 minutes respectively, wash and dry;

[0029] (2) Put the dried copper mesh into 1M ethanol solution of dodecanethiol, soak for 3 hours, take it out, rinse it with absolute ethanol three times, and dry it at 60°C to obtain a hydrophobic copper mesh.

[0030] (3) Put the hydrophobic copper net into 0.05M NaOH solution, take the copper net as the anode and the copper wire as the cathode, at a voltage of 3V, the diameter of the copper wire is 1mm, and the distance between the cathode and the anode is 0.5mm Under the same conditions, the anodic oxidation was carried out for 120s to obtain a circular wettable gradient copper mesh imitating the beetle structure.

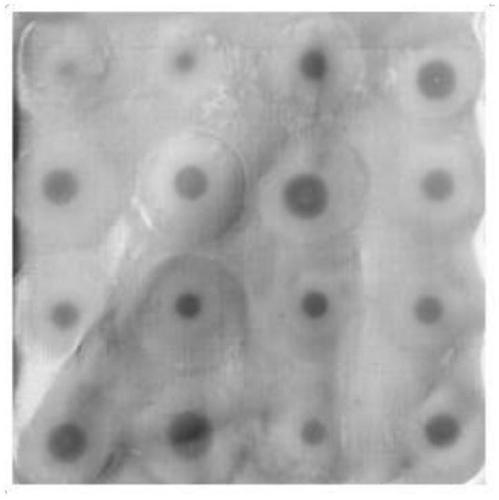

[0031] The resulting circular wettable gradient copper mesh, as figure 2 As shown, its surface has a ...

Embodiment 2

[0034] The preparation method of annular wettable gradient copper mesh, the specific steps are as follows:

[0035] (1) Put the 180-mesh red copper net of 16cm×16cm into 0.1% nitric acid, acetone, and ethanol solution for 15 minutes respectively, wash and dry;

[0036] (2) Put the dried copper mesh into 1M ethanol solution of dodecanethiol, soak for 3 hours, take it out, rinse it with absolute ethanol three times, and dry it at 60°C to obtain a hydrophobic copper mesh.

[0037] (3) Put the hydrophobic copper mesh into the 0.05M NaOH solution, take the copper mesh as the anode and the copper wire as the cathode, the distance between adjacent copper wires is 3cm, the voltage is 8V, and the diameter of the cathode is 1mm , under the condition that the distance between the anode and the cathode is 0.5mm, the anodization is carried out for 120s to obtain a ring-shaped wettable gradient copper mesh imitating the beetle structure.

[0038]The surface of the prepared annular wettabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com