Treatment method of drilling waste

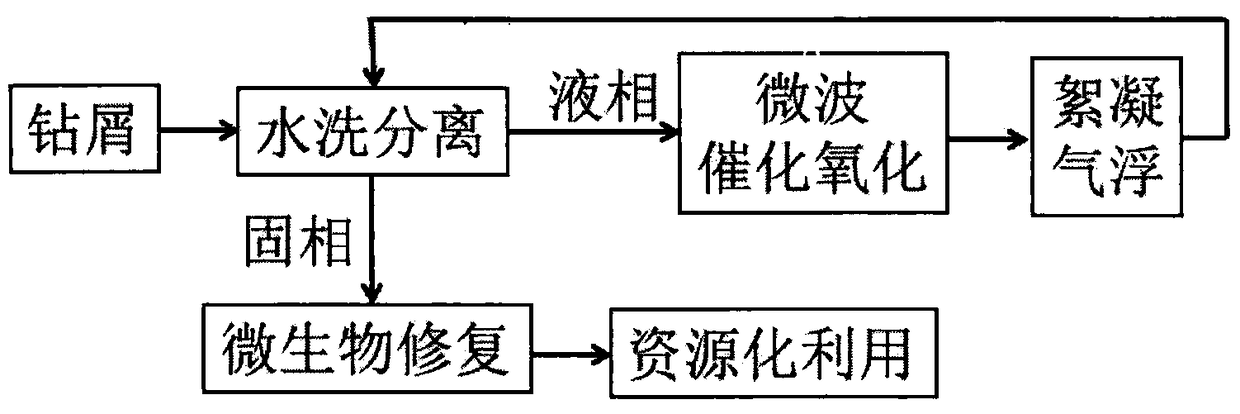

A drilling waste and treatment method technology, applied in the field of drilling waste treatment, can solve the problems of complex operating conditions, low oil content, high treatment cost, etc., and achieve the effects of short process flow, short treatment time and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Treatment of drilling waste in Xinjiang Oilfield:

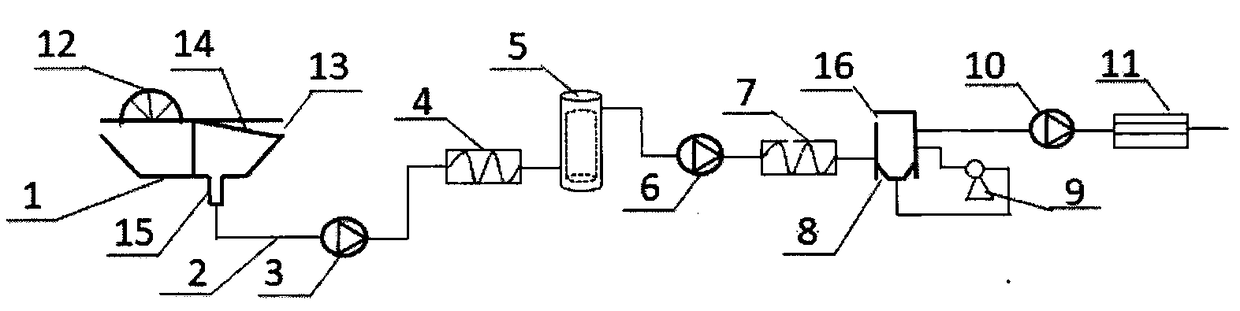

[0029]A treatment method for drilling waste according to the present invention, the treatment device involved in the method is composed of a water washing separator 1, an impeller 12, a cuttings discharge port 13, a vibrating screen 14, a water discharge port 15, a pipeline 2, a first Water pump 3, first dosing mixer 4, microwave reactor 5, second water pump 6, second dosing mixer 7, air flotation device 8, air flotation device slag outlet 16, dissolved air pump 9, third water pump 10 Composed of a magnetizer 11, one end of the microwave reactor 5 is connected in series with the drain outlet 15 at the bottom of the first dosing mixer 4, the first water pump 3 and the vibrating screen 14 respectively through the pipeline 2, and the vibrating screen 14 is connected with the washing separator 1 , the top of the vibrating screen 14 is provided with a debris discharge port 13, the mesh size of the vibrating screen 14 is 0.1...

Embodiment 2

[0035] Treatment of drilling waste in Tarim Oilfield:

[0036] The processing device of the present embodiment is carried out according to embodiment 1, and concrete operation is carried out according to the following steps:

[0037] a. The drill cuttings separated by the vibrating screen 14 are imported into the cleaning area in the water washing separator 1 according to the weight ratio drill cuttings:cleaning liquid=1:5, and first pass through the agitation of the impeller 12 and the vibration of the ultrasonic vibrator to clean the drill cuttings. The cleaned cuttings are brought to the spraying area by the wheel bucket, and further cleaned under the action of spraying. The sprayed cuttings are sent to the vibrating screen 14 for dehydration treatment. The water content in the treated cuttings The rate is 11%, and the processing capacity of solid cuttings is 2 cubic meters per hour;

[0038] b. The solid phase separated after the dehydration treatment in step a is transfe...

Embodiment 3

[0042] Treatment of drilling waste in Tuha Oilfield:

[0043] The processing device of the present embodiment is carried out according to embodiment 1, and concrete operation is carried out according to the following steps:

[0044] a. The drill cuttings separated by the vibrating screen 14 are imported into the cleaning area in the water washing separator 1 according to the weight ratio drill cuttings:cleaning liquid=1:7. The cleaned cuttings are brought to the spraying area by the wheel bucket, and further cleaned under the action of spraying. The sprayed cuttings are sent to the vibrating screen 14 for dehydration treatment. The water content in the treated cuttings The rate is 10%, and the processing capacity of solid cuttings is 3.5 cubic meters per hour;

[0045] b. The solid phase separated after the dehydration treatment in step a is transferred to the bioremediation field for microbial remediation treatment. After 60 days of bioremediation, the oil content in the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com