Frozen wall enclosure structure in portal ring beam construction and construction method thereof

A technology of enclosure structure and freezing wall, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of uneven reinforcement, large dispersion of reinforcement, poor excavation safety, etc., and achieves a large and uniform freezing range. Good sex, low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

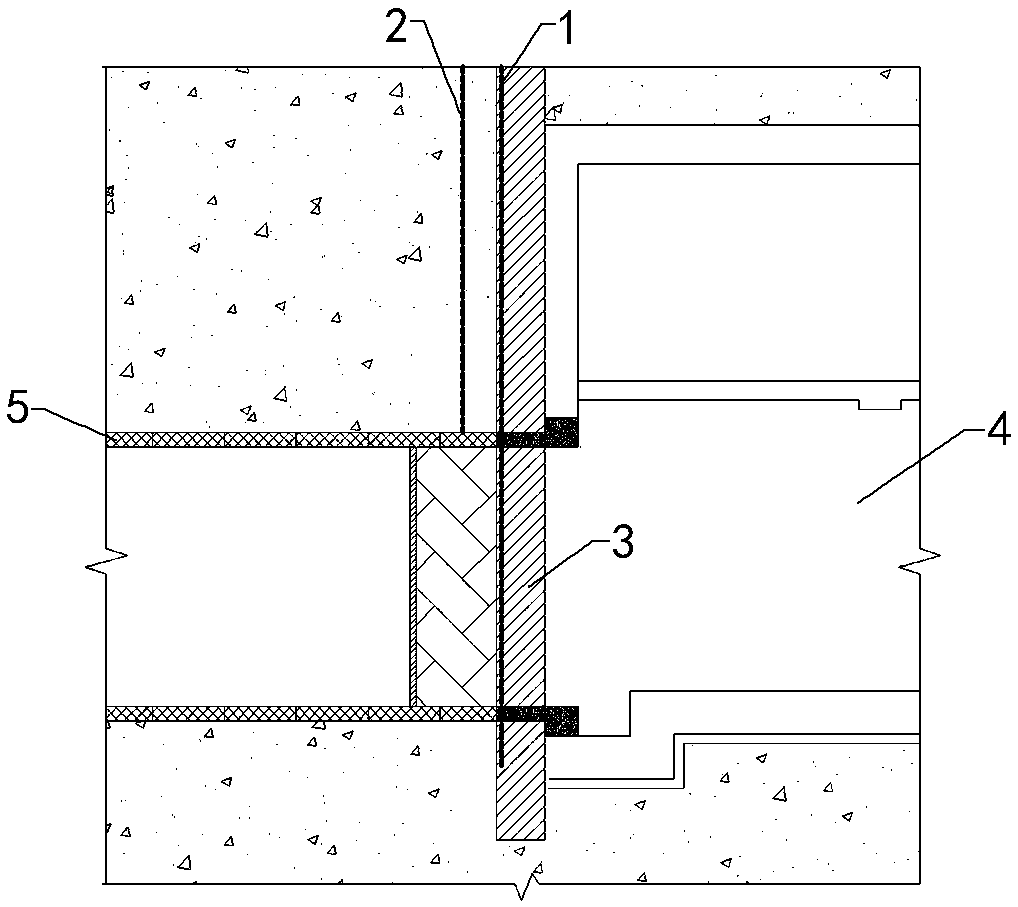

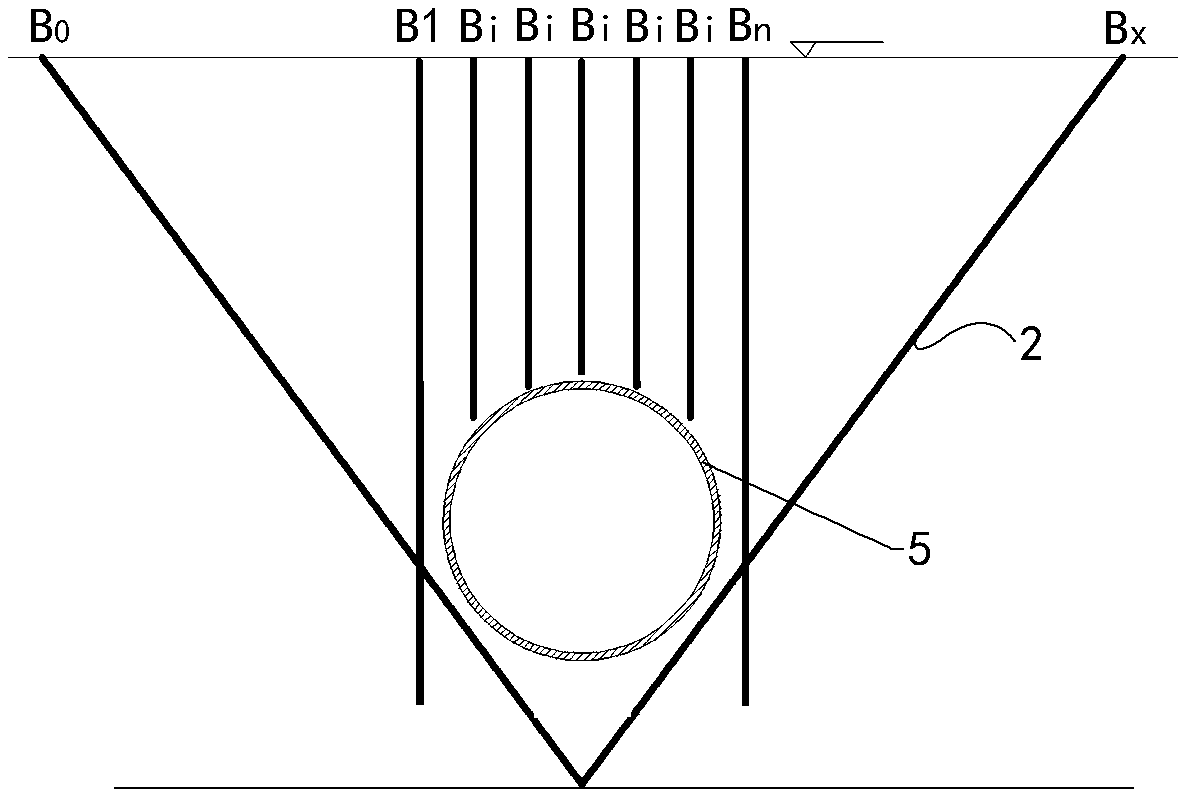

[0043] Such as Figure 1 to Figure 5 As shown, the frozen wall enclosure structure in the construction of the portal ring beam of the present invention includes the A row of frozen pipes 1 and the B row of frozen pipes 2 arranged at the junction of the station foundation pit 4 and the tunnel segment 5; After the liquid nitrogen and brine are sequentially injected into the freezing pipe 2 of row B, a freezing layer with a thickness not less than 1.5 times the width of the door ring beam will be formed at the junction of the station foundation pit 4 and the tunnel segment 5 and in the strata around the tunnel segment 5. Wall 6 enclosure structure.

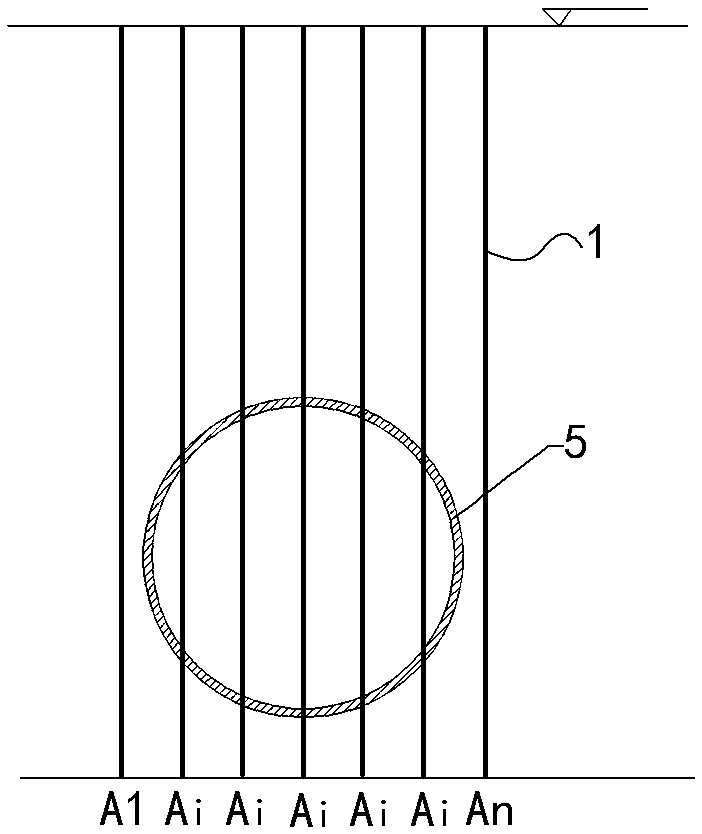

[0044] Such as figure 2 As shown, the A row of frozen pipes 1 is located in the existing occlusal pile 3 of the station foundation pit 4, and is driven vertically from the ground. 1 is a pipe curtain composed of frozen pipes arranged side by side along the longitudinal section perpendicular to the horizontal axis of the tunnel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com