High-resolution surface testing method

A surface testing, high-resolution technology, used in measuring devices, analyzing materials, and using wave/particle radiation for material analysis. , sharp focus beam spot, optimize the effect of focusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

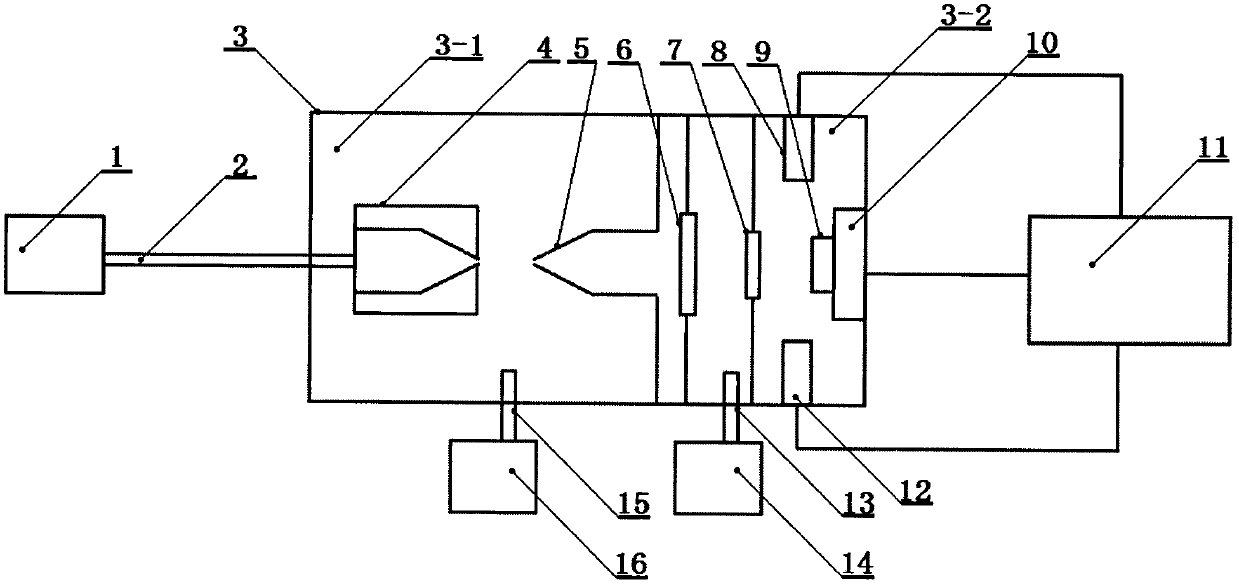

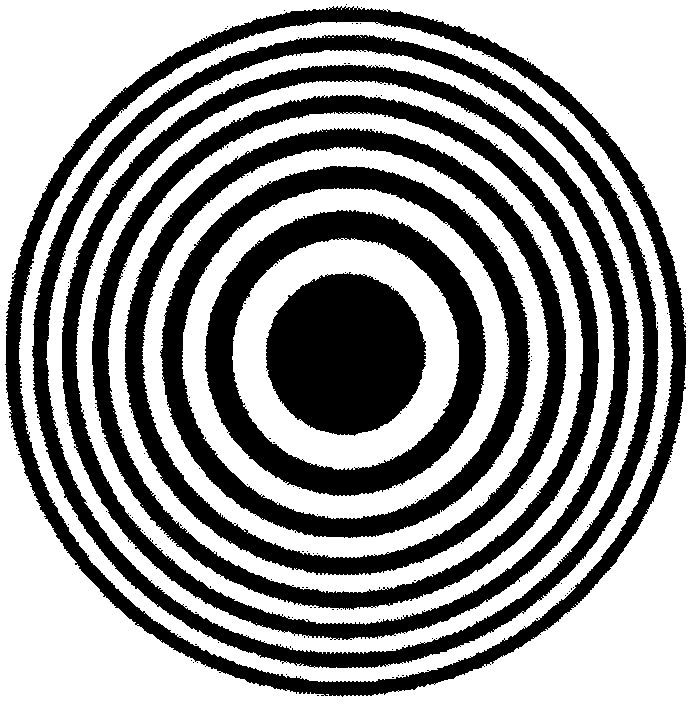

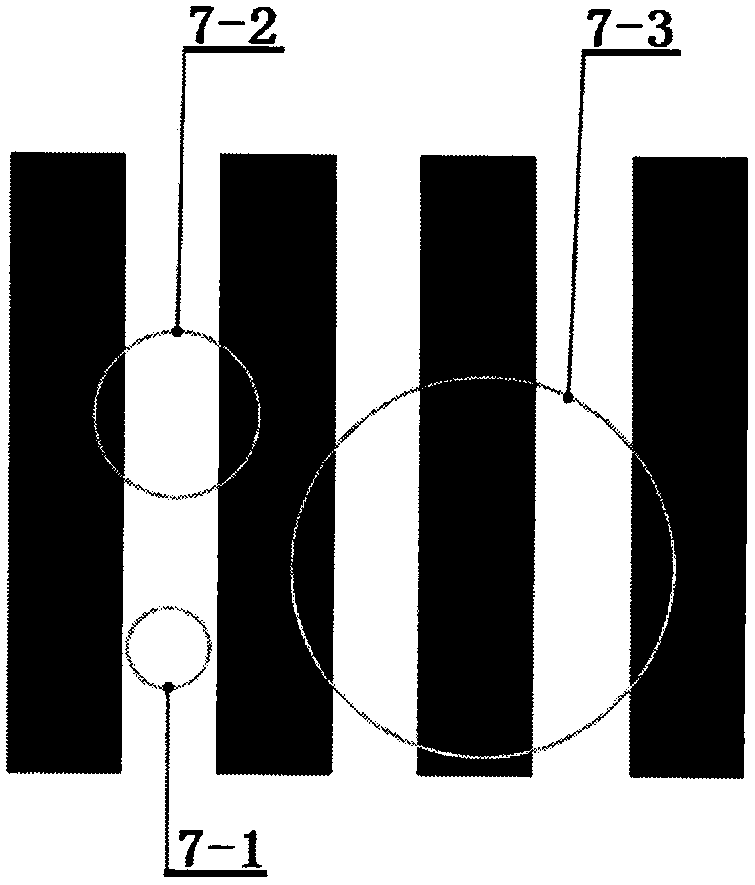

[0027] Such as figure 1 It is a schematic diagram of the high-resolution surface testing device of the present invention. The high-resolution surface testing device mainly includes a gas storage tank (1), a gas pipe (2), and is connected by a cavity I (3-1) and a cavity II (3-2). Vacuum cavity (3), injection head (4), flow divider (5), gas transmission window (6), atomic diffraction sheet (7), atomic diffraction sheet through hole type I (7-1), atomic Diffraction sheet through-hole type II (7-2), atomic diffraction sheet through-hole type III (7-3), detector I (8), sample (9), sample stage (10), computer (11), detector II(12), suction port I(13), vacuum pump group I(14), gas suction port II(15), vacuum pump group II(16), the cavity I(3-1) and cavity II(3- 2) Connected through the flow divider (5), the cavity II (3-2) is connected to the vacuum pump group I (14) through the suction port I (13), and the cavity I (3-1) is connected to the vacuum pump through the suction port II (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com