Two-column separation detection system and detection method based on heart cutting

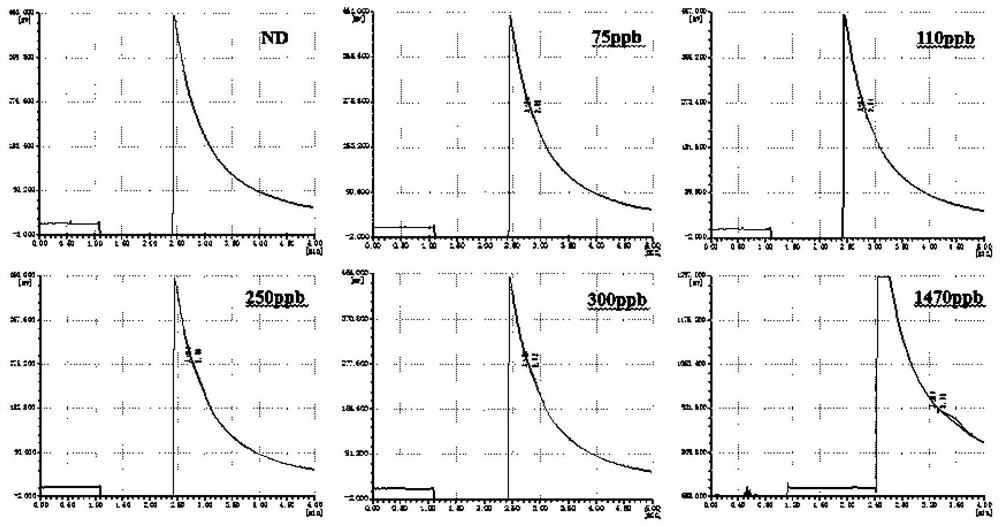

A heart-cutting and detection system technology, which is applied in material separation, measuring devices, and analysis of materials, etc., can solve problems such as difficulty in guaranteeing the detection limit of 100 ppb impurities, high detection limit, and difficulty in meeting the 100 ppb standard, so as to improve the detection limit problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

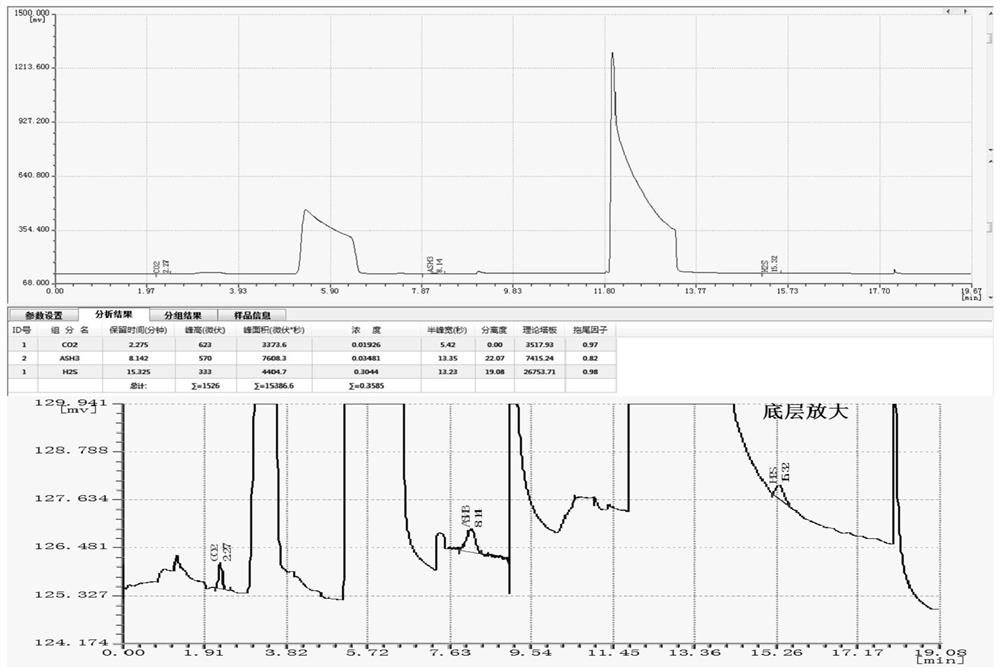

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

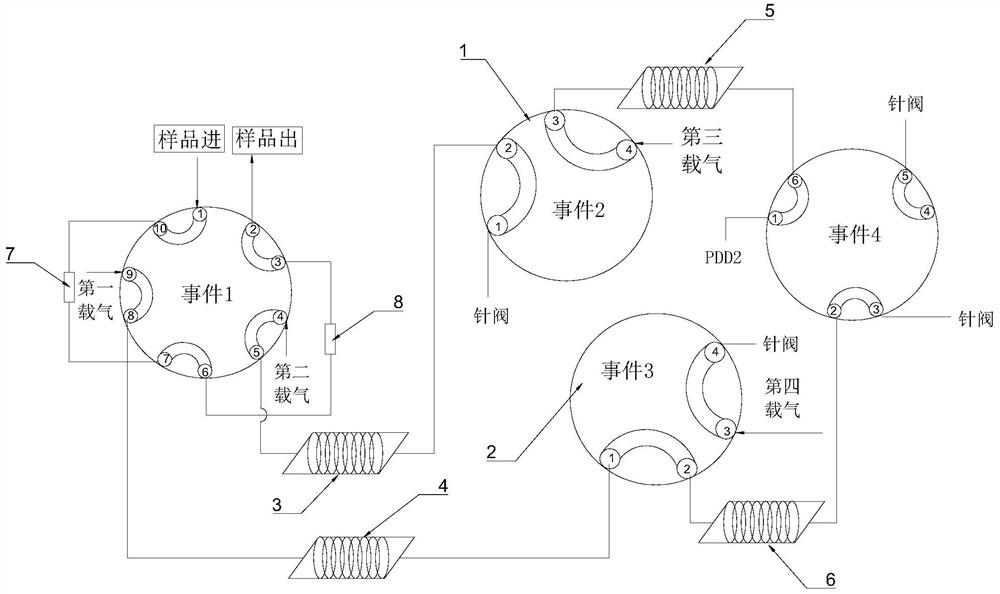

[0032] Such as figure 1 , figure 2 As shown, the heart-cutting-based double-column separation detection system includes a front-stage venting column, a rear-stage separation column, a first four-way valve 1, a second four-way valve 2, a ten-way valve, and a six-way valve; The vent column includes a first vent column 3 and a second vent column 4; the post-stage separation column includes a first separation column 5 and a second separation column 6;

[0033] The ten-way valve includes ports 1 to 10, wherein port 1 and port 2 are sample inlet and sample outlet respectively, port 9 and port 4 are respectively the first carrier gas inlet and the second carrier gas inlet, 5 Port No. 1 is connected to the air inlet of the first venting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com