Printed circuit board (PCB) high current test method

A test method and high-current technology, applied in the direction of electronic circuit testing, automated test systems, measuring electricity, etc., can solve the problems of destructive verification, inner-layer circuit connection problems, and high levels, to avoid scrap loss, adjustment and improvement, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A PCB high current test method, specifically including the following steps:

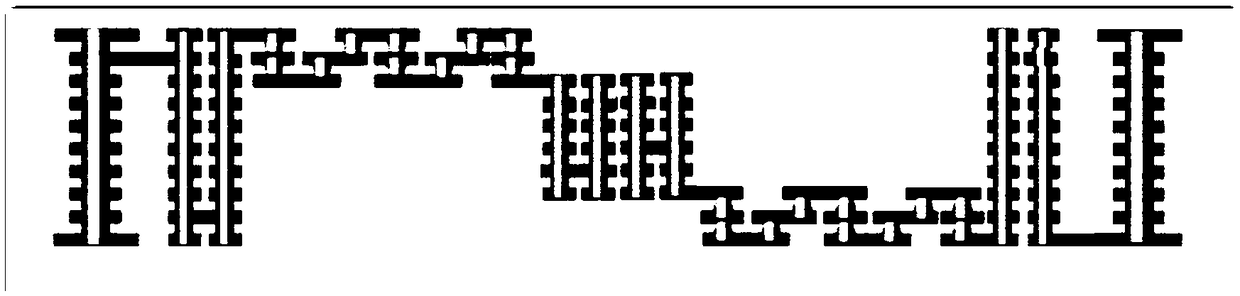

[0038] S1. Front resistance measurement: Use a four-wire micro-resistance meter to measure the resistance of both ends of the HCT Coupon test loop, (HCT Coupon wiring indication figure 1 (Shown), this link can detect PCB plating incompleteness problems. If the measured resistance value has a large deviation from the theoretical resistance value, the problem is mainly caused by the following possible factors such as: electroplating laser blind hole / through hole Hole breakage, laser blind hole missed / impermeable / small hole diameter, mechanical drilling missed drilling or drilling offset, compression combination group staggered type, etc.;

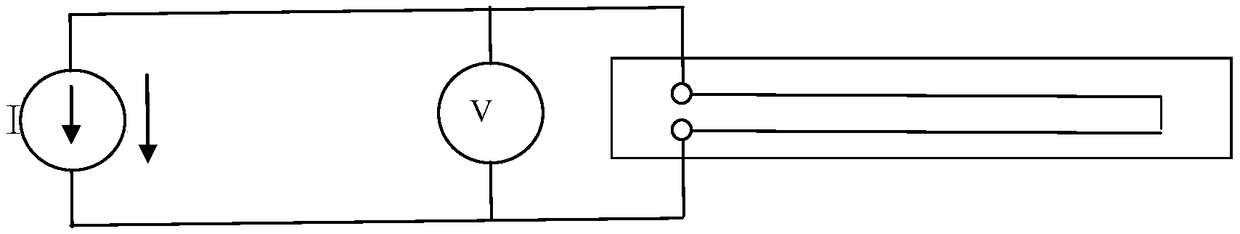

[0039] S2. If the front resistance test is passed, it will enter the high current test link (this link is to simulate high temperature production processes such as PCB overheated air reflow furnace or wave soldering, and the normal temperature in this process is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com