A internal oxygen self-absorption safe lithium battery

A technology for oxygen absorption and lithium batteries, which is applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of thermal runaway and fire of lithium batteries, and achieve the effect of improving cycle life and avoiding fire from thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

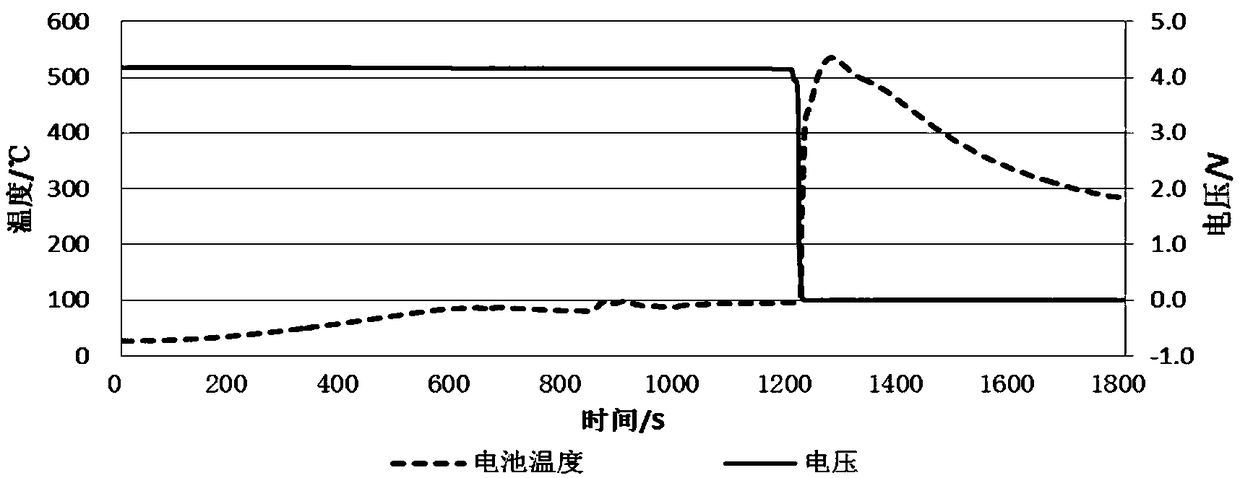

Embodiment 1

[0054] An internal oxygen self-absorption safety lithium battery, the lithium battery includes a positive electrode sheet, a negative electrode sheet; the positive electrode sheet is made of raw materials comprising the following parts by weight: LiNi 0.5 co 0.2 mn 0.3 o 2 94kg, carbon black 3kg, PVDF 2kg, NMP 70kg, activated carbon 2kg; the pore size range of activated carbon is 0.3-0.6nm; the size of the oxygen absorbing additive is 10-100um;

[0055] The negative electrode sheet is made of the following raw materials in parts by weight: graphite 50kg, CMC 0.80kg, SBR 1.0kg, carbon black 0.7kg, deionized water 60kg.

[0056] The lithium battery also includes a membrane structure, which is a microporous diaphragm with a polyolefin substrate thickness of 12um and an aluminum oxide coating thickness of 4um.

[0057] The lithium battery also includes an electrolyte, which mixes EC, PC, and EMC at a volume ratio of 35:5:60, and adds LiPF at a lithium salt concentration of 1.0M...

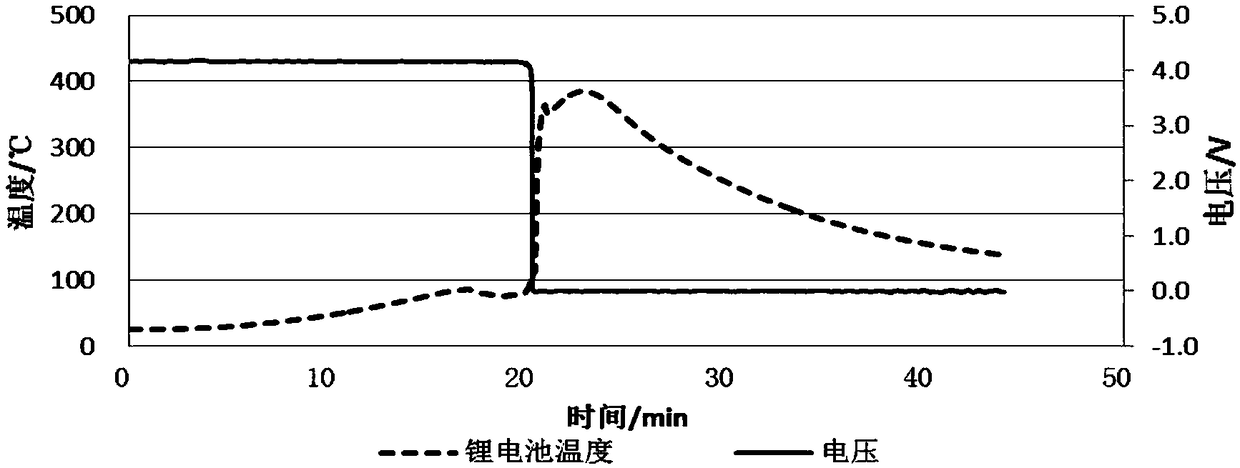

Embodiment 2

[0061] An internal oxygen self-absorption safety lithium battery, the lithium battery includes a positive electrode sheet, a negative electrode sheet; the positive electrode sheet is made of raw materials comprising the following parts by weight: LiNi 0.5 co 0.2 mn 0.3 o 2 94kg, carbon black 3kg, PVDF 2kg, NMP 70kg, activated carbon 4kg; the pore size of the activated carbon is 0.3-0.6nm; the size of the oxygen absorbing additive is 10-100um;

[0062] The negative electrode sheet is made of the following raw materials in parts by weight: graphite 50kg, CMC 0.80kg, SBR 1.0kg, carbon black 0.7kg, deionized water 60kg.

[0063] The lithium battery also includes a membrane structure, which is a microporous diaphragm with a polyolefin substrate thickness of 12um and an aluminum oxide coating thickness of 4um.

[0064] The lithium battery also includes an electrolyte, which mixes EC, PC, and EMC at a volume ratio of 35:5:60, and adds LiPF at a lithium salt concentration of 1.0M ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com