A novel active-passive combined thermodynamic cooling device

An active-passive combined technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of high energy consumption and high failure rate, and achieve the effects of long air supply distance, energy saving and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

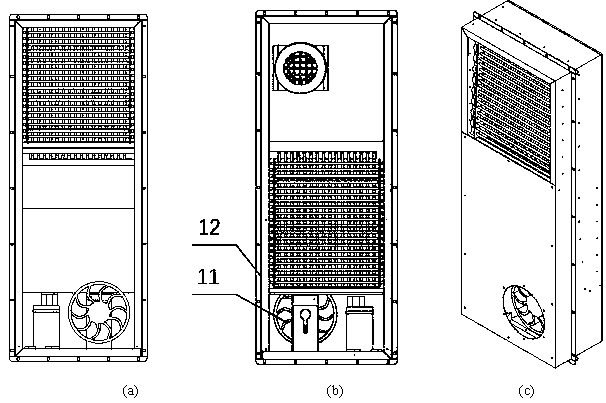

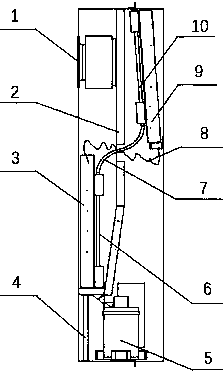

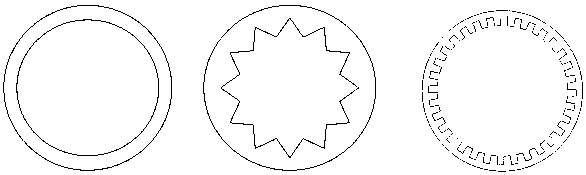

[0014] Such as figure 1 and 2 As shown, a new type of active-passive combined thermal cycle equipment involved in the present invention mainly includes an internal circulation fan 1, an isolation plate 2, an active evaporator 3, a compressor 4, a drain pipe 5, a heat pipe evaporation section 6, a heat pipe 7, a section A flow element 8, an active condenser 9, a heat pipe condensation section 10, an external circulation fan 11, and a casing 12. In this device, all the components are placed in the housing 12, and the isolation plate 2 isolates the housing 12 into two areas, the inner area and the outer area. The inner area is mainly composed of the active evaporator 3, the heat pipe evaporation section 6 and the internal circulation fan 1. , the outer area is mainly composed of a compressor 4, an external circulation fan 11, an active condenser 9 and a heat pipe condensing section 10. The main function of the drain pipe 5 is to discharge the condensed water produced by the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com