Grain bread fermenting technology

A fermentation process and bread technology, which is applied in the field of food processing, can solve the problems of rough texture, subsidence and potholes, hard skin, etc., and achieve the effect of improving baking quality and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

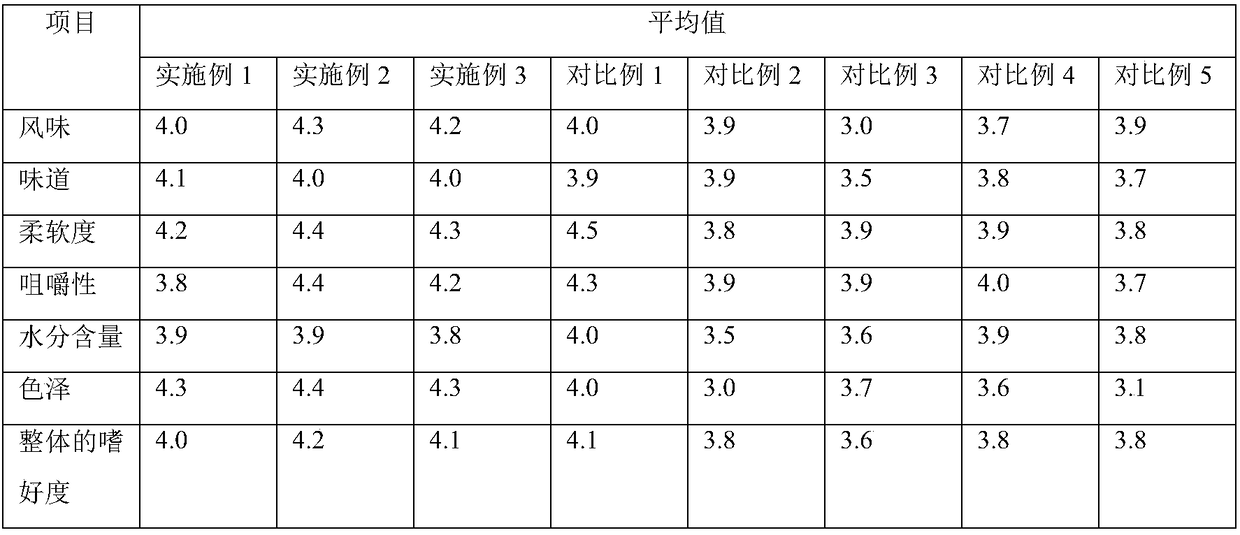

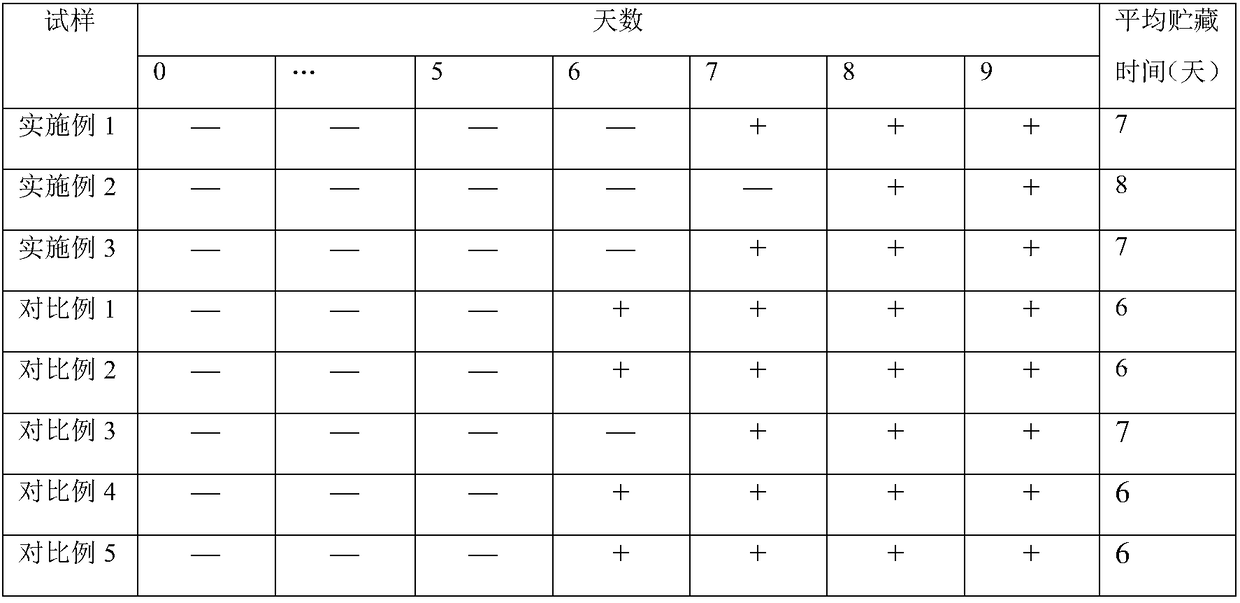

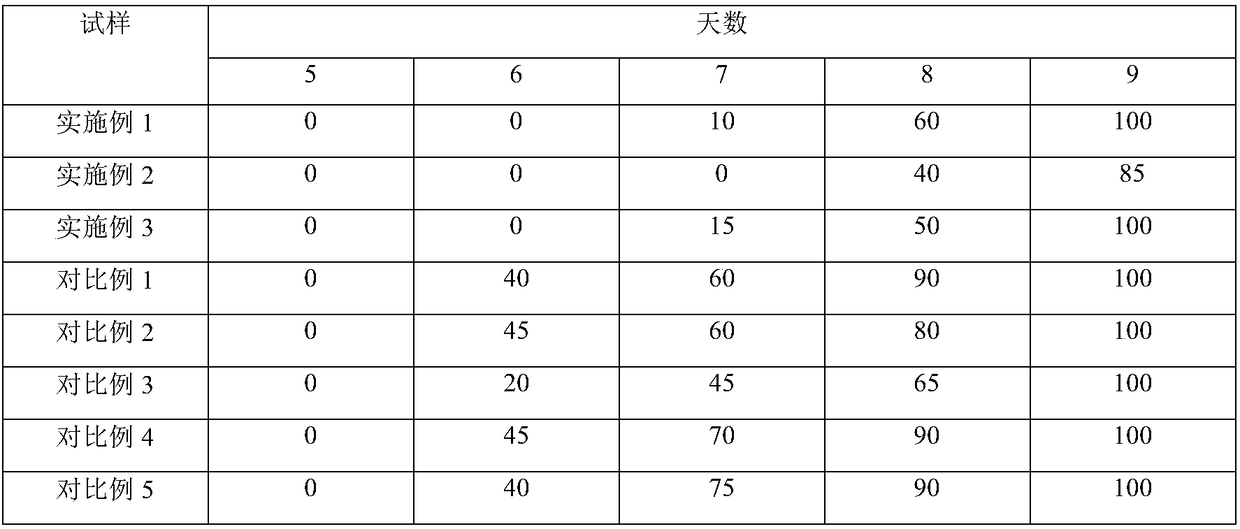

Examples

Embodiment 1

[0033] A method for fermenting cereal bread, comprising the following steps:

[0034] S1, one-time powder adjustment: mix 600 parts by weight of water, 10 parts by weight of white granulated sugar, 55 parts by weight of eggs and 50 parts by weight of bread improver to obtain an aqueous mixture. At the same time, 300 parts by weight of wheat flour after sieving, 550 parts by weight of The rye flour is mixed with 20 parts by weight of milk powder, 4.6 parts by weight of dry yeast after activation and 10 parts by weight of lactic acid bacteria are added to the mixture of wheat flour and rye flour, mixed and stirred to obtain a flour mixture, and the aqueous mixture and the flour mixture are mixed and stirred until The surface of the dough is rough and gluten is formed;

[0035] Wherein, the specific operation of the activation treatment of dry yeast is: dissolving 6 parts by weight of dry yeast in 20 parts by weight of water with a temperature of 30°C, and mixing with other raw m...

Embodiment 2

[0041] A method for fermenting cereal bread, comprising the following steps:

[0042]S1, one-time powder adjustment: mix 680 parts by weight of water, 12 parts by weight of white granulated sugar, 62 parts by weight of eggs and 65 parts by weight of bread improver to obtain a water-containing mixture. At the same time, 350 parts by weight of wheat flour after sieving, 610 parts by weight of The rye flour is mixed with 32 parts by weight of milk powder, 5.3 parts by weight of dry yeast after activation and 18 parts by weight of lactic acid bacteria are added to the mixture of wheat flour and rye flour, mixed and stirred to obtain a flour mixture, and the aqueous mixture and the flour mixture are mixed and stirred until The surface of the dough is rough and gluten is formed;

[0043] Wherein, the specific operation of the activation treatment of dry yeast is: dissolving 6.5 parts by weight of dry yeast in 27 parts by weight of water with a temperature of 35°C, and mixing it with...

Embodiment 3

[0049] A method for fermenting cereal bread, comprising the following steps:

[0050] S1, one-time powder adjustment: mix 735 parts by weight of water, 15 parts by weight of white granulated sugar, 70 parts by weight of eggs and 80 parts by weight of bread improver to obtain a water-containing mixture. At the same time, 400 parts by weight of wheat flour after sieving, 670 parts by weight of The rye flour is mixed with 45 parts by weight of milk powder, 7 parts by weight of dry yeast after activation and 25 parts by weight of lactic acid bacteria are added to the mixture of wheat flour and rye flour, mixed and stirred to obtain a flour mixture, and the aqueous mixture and the flour mixture are mixed and stirred until The surface of the dough is rough and gluten is formed;

[0051] Wherein, the specific operation of the activation treatment of dry yeast is: dissolving 7 parts by weight of dry yeast in 35 parts by weight of water with a temperature of 40°C, and mixing it with ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com