Continuous preparation method of phosphorus pentafluoride

A technology of phosphorus pentafluoride and fluorine gas, applied in the field of continuous preparation of phosphorus pentafluoride, can solve the problems of unfavorable reaction rate, uncontrolled reaction, high safety risk, etc., to reduce safety risks, avoid explosion accidents, and easily react control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

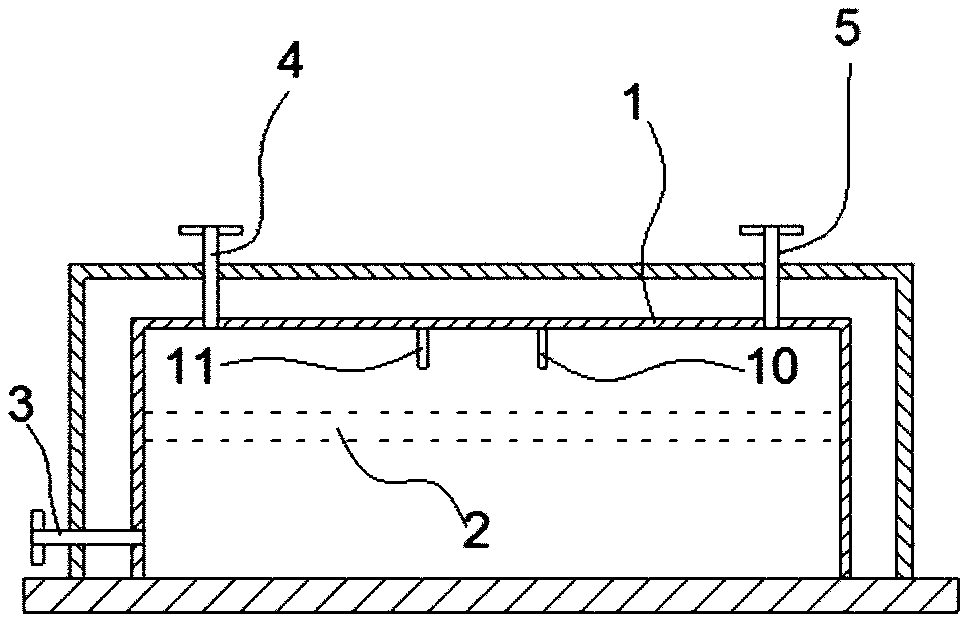

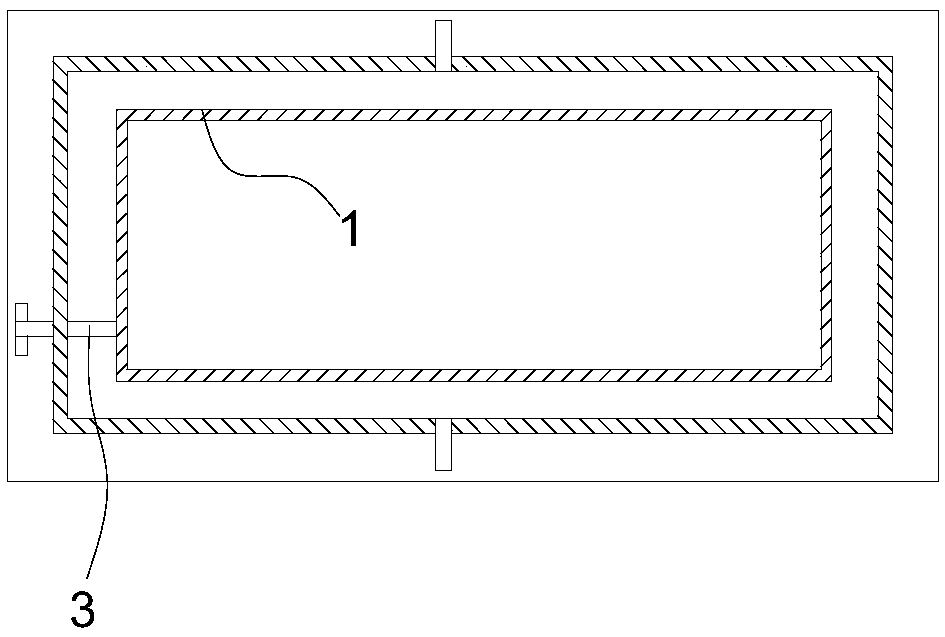

[0030] Such as figure 1 and figure 2 Shown, adopt following equipment and process to prepare phosphorus pentafluoride. The production equipment that adopts comprises horizontal reaction vessel 1, has the liquid level keeping section 2 of certain height in the inner chamber of described horizontal reaction vessel 1, and the area of the horizontal section of arbitrary height position of described liquid level keeping section 2 is equal, A liquid inlet channel 3 is provided below the liquid level maintaining section 2 , an inlet channel 4 is provided at one end of the upper horizontal reaction vessel 1 , and an exhaust channel 5 is provided at the other end. The horizontal reaction vessel 1 adopts a high-temperature and high-pressure resistant reactor, the liquid inlet channel 3 is used to continuously pass liquid yellow phosphorus into the horizontal reaction vessel 1, and the gas inlet channel 4 is used to continuously pass fluorine gas into the horizontal reaction vessel 1...

Embodiment 2

[0033] Adopt the equipment described in embodiment 1 to carry out the production of phosphorus pentafluoride, only change the parameter of part, wherein, control yellow phosphorus liquid level constant to be 0.1m 2 , the feed rate of fluorine gas is 0.5m / s, and the reaction temperature is controlled to be 100°C. The distance between the inlet of fluorine gas and the liquid surface of yellow phosphorus is kept at 50-80mm. The temperature detector 10 detects the reaction temperature in the horizontal reaction vessel 1, and the pressure detector 11 detects the reaction pressure in the horizontal reaction vessel 1. Through monitoring, it can be seen that the reaction temperature fluctuates within 80-120°C using this process, and the reaction The pressure fluctuates within 0.1-0.2 MPa, the fluctuation of reaction temperature and reaction pressure is small, and the reaction proceeds smoothly.

Embodiment 3

[0035] Adopt the equipment described in embodiment 1 to carry out the production of phosphorus pentafluoride, only change the parameter of part, wherein, control yellow phosphorus liquid surface area constant to be 2m 2 , the feed rate of fluorine gas is 2m / s, and the reaction temperature is controlled at 200°C. The distance between the inlet of fluorine gas and the liquid surface of yellow phosphorus is kept at 80-120mm. The temperature detector 10 detects the reaction temperature in the horizontal reaction vessel 1, and the pressure detector 11 detects the reaction pressure in the horizontal reaction vessel 1. Through monitoring, it can be known that the reaction temperature fluctuates within 180-220°C with this process, and the reaction The pressure fluctuates within 0.1-0.2 MPa, the fluctuation of reaction temperature and reaction pressure is small, and the reaction proceeds smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com