High performance microwave dielectric ceramic material with low dielectric constant as well as preparation method and application of ceramic material

A technology of microwave dielectric ceramics and low dielectric constant is applied in the fields of low dielectric constant and high performance microwave dielectric ceramic materials, preparation, ceramic materials and their preparation. Cost and other issues, to achieve the effect of reducing the defective rate and overall manufacturing cost, the preparation process is simple, and the preparation process is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

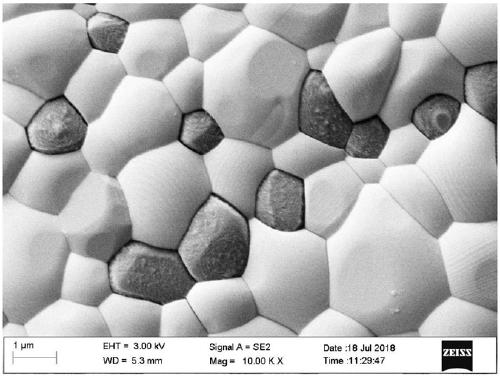

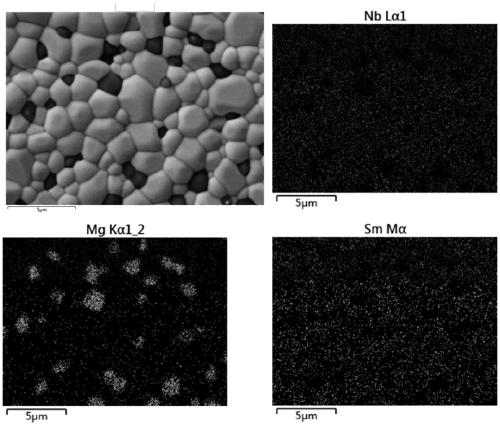

Image

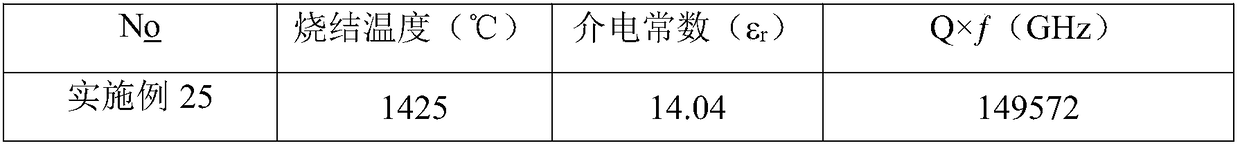

Examples

Embodiment 1

[0029] According to the chemical formula SmNbO 4 The stoichiometric ratio of each element in -0.5MgO, respectively weighed Sm 2 o 3 (Analytical pure) 13.3146g, Nb 2 o 5 (analytical pure) 10.1468g, MgO (analytical pure) 1.5386g; weigh the powder by Sm 2 o 3 , MgO, Nb 2 o 5 Sequentially put into ball milling tanks, use absolute ethanol as the ball milling medium, and ball mill and mix for 6 hours; after ball milling, the raw materials are dried and sieved, put into alumina crucibles, and heated to 1100°C in a muffle furnace for calcination for 2 hours; The calcined powder was ball milled again with absolute ethanol as the ball milling medium for 24 hours, dried, sieved, added paraffin and fried evenly, and passed through an 80-mesh sieve; poured an appropriate amount of powder into the mold, and used a powder tablet press at 200MPa A cylindrical sample of φ10mm×5mm was made under a certain pressure; finally, the sample was put into a high-temperature box furnace for sinte...

Embodiment 7

[0037] According to the chemical formula SmNbO 4 The stoichiometric ratio of each element in -1MgO, respectively weighed Sm 2 o 3 (Analytical pure) 12.5427g, Nb 2 o 5 (analytical pure) 9.5585g, MgO (analytical pure) 2.8987g; weigh the powder by Sm 2 o 3 , MgO, Nb 2 o 5 Sequentially put into ball milling tanks, use absolute ethanol as the ball milling medium, and ball mill and mix for 6 hours; after ball milling, the raw materials are dried and sieved, put into alumina crucibles, and heated to 1100°C in a muffle furnace for calcination for 2 hours; The calcined powder was ball milled again with absolute ethanol as the ball milling medium for 24 hours, dried, sieved, added paraffin and fried evenly, and passed through an 80-mesh sieve; poured an appropriate amount of powder into the mold, and used a powder tablet press at 200MPa A cylindrical sample of φ10mm×5mm was made under a certain pressure; finally, the sample was put into a high-temperature box furnace for sinterin...

Embodiment 13

[0043] According to the chemical formula SmNbO 4 The stoichiometric ratio of each element in -2MgO, respectively weighed Sm 2 o 3 (Analytical pure) 11.2395g, Nb 2 o 5 (analytical pure) 8.5654g, MgO (analytical pure) 5.1951g; 2 o 3 , MgO, Nb 2 o 5 Sequentially put into ball milling tanks, use absolute ethanol as the ball milling medium, and ball mill and mix for 6 hours; after ball milling, the raw materials are dried and sieved, put into alumina crucibles, and heated to 1100°C in a muffle furnace for calcination for 2 hours; The calcined powder was ball milled again with absolute ethanol as the ball milling medium for 24 hours, dried, sieved, added paraffin and fried evenly, and passed through an 80-mesh sieve; poured an appropriate amount of powder into the mold, and used a powder tablet press at 200MPa A cylindrical sample of φ10mm×5mm was made under a certain pressure; finally, the sample was put into a high-temperature box furnace for sintering, the sintering temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com