A kind of production process of n-butane oxidation to maleic anhydride

A n-butane and process technology, which is applied in the production process field of maleic anhydride, can solve problems such as scrapping and unstable operation, and achieve the effects of improving production profit, good selectivity and yield, and good economic benefits

Active Publication Date: 2022-06-10

常州新日催化剂股份有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

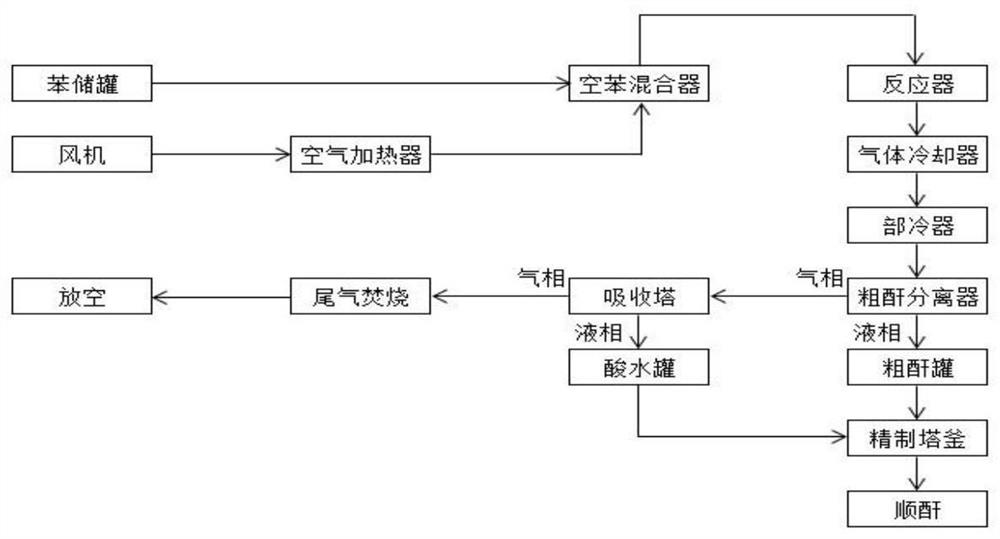

Due to the restriction of catalyst operating conditions, the existing vanadium phosphorus oxygen catalyst cannot run stably on the production device of maleic anhydride by benzene oxidation

Therefore, the original maleic anhydride plant by benzene oxidation method is usually scrapped

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

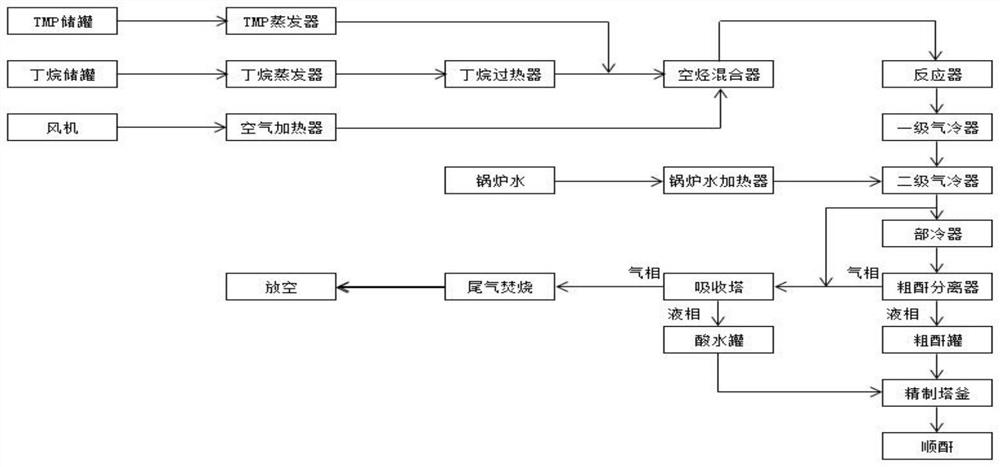

The invention discloses a process for preparing maleic anhydride by oxidation of n-butane, which belongs to the field of maleic anhydride production. The invention obtains a production process for producing maleic anhydride by n-butane oxidation at a lower operating pressure by improving the production process for producing maleic anhydride by the original benzene oxidation method. In particular, the process uses a self-made catalyst, so that the reaction has better selectivity and yield under low pressure conditions, and at the same time, it not only revitalizes the existing process but also saves costs.

Description

A kind of production process of n-butane oxidation to maleic anhydride technical field The present invention relates to the production field of maleic anhydride, more specifically, relate to a kind of use n-butane under lower operating pressure The production process of alkoxylation to produce maleic anhydride. Background technique Maleic anhydride is called maleic anhydride for short, has another name called maleic anhydride, is a kind of important organic chemical raw material, is second only to benzene Anhydride and acetic anhydride, the world's third largest organic acid anhydride, is widely used in petrochemical, food processing, medicine, building materials and other industries. due to the The raw materials are cheap, the pollution is relatively light, the carbon atom utilization rate is high and the production cost of maleic anhydride is low. Technology has gradually become the main route of maleic anhydride production, and there is a tendency to gradually re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07D307/60

CPCC07D307/60

Inventor 刘先国魏士新邹红旭王康军胡佳陈鹏宋大朋石龙

Owner 常州新日催化剂股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com