A class of alcohol-substituted two-dimensional layered germane and its preparation method

A two-dimensional layered, germane technology, applied in the direction of germanium organic compounds, etc., can solve the problem of low band gap value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

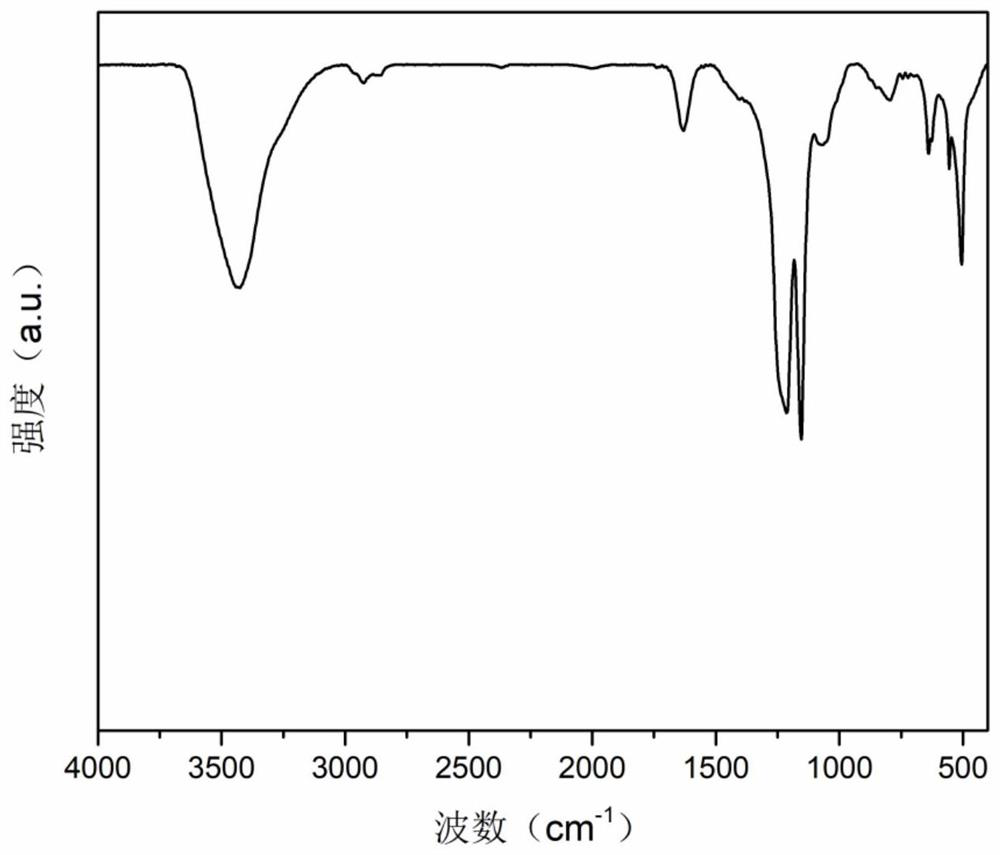

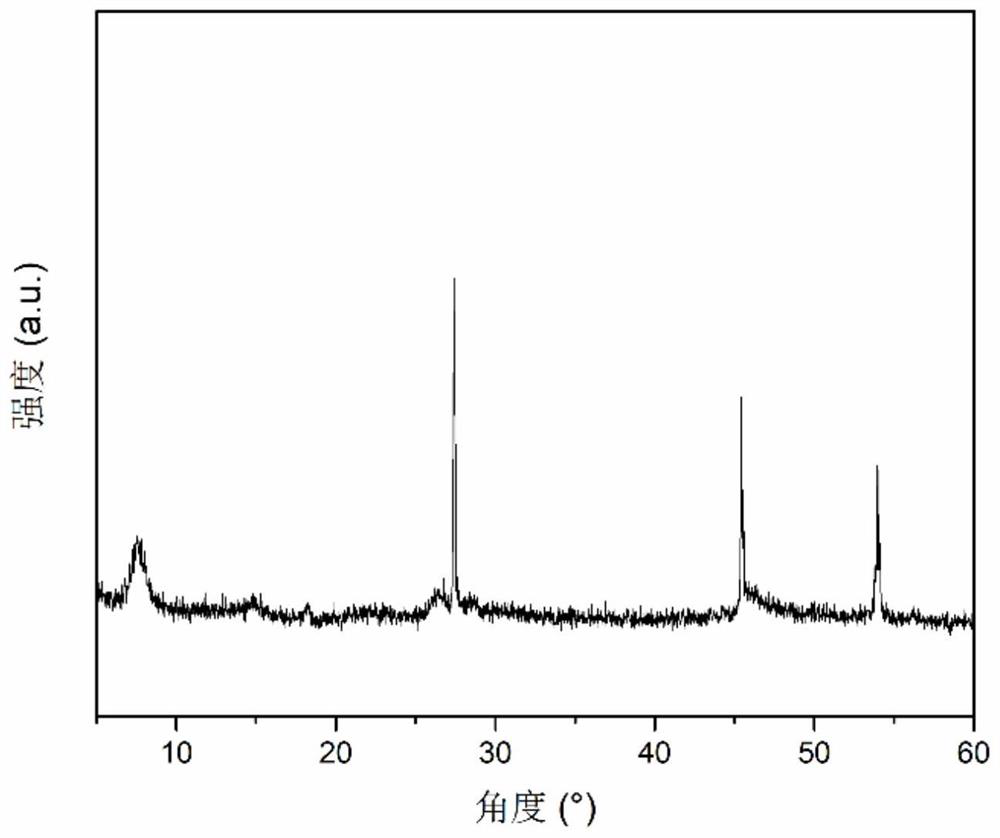

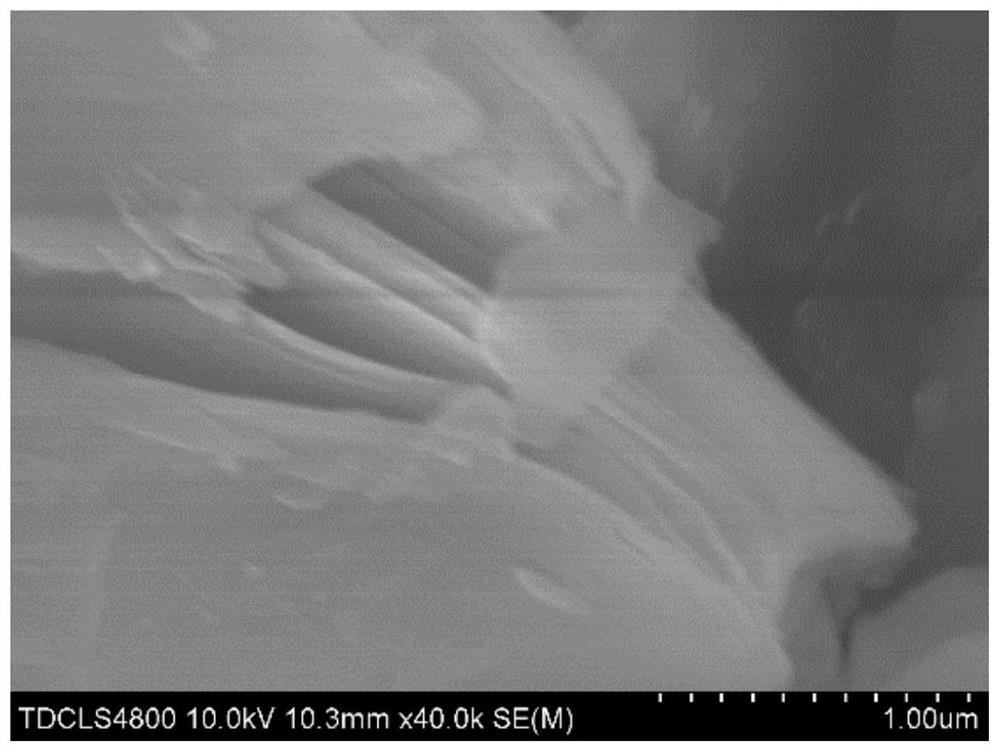

Method used

Image

Examples

example 1

[0022] Weigh 200mg (0.001mol) CaGe 2 , dispersed in 20ml of acetonitrile, under nitrogen protection, add 108ul (0.006mol) ultrapure water, add 1.7ml (0.02mol) iodine ethanol under dark conditions, stir and react at 200r / min in a constant temperature water bath at room temperature for 5 sky. The product was washed with 40ml of deionized water, then suction-filtered, and washed repeatedly three times (a total of 120ml of deionized water was used). Then washed three times with isopropanol in the same manner (the amount of isopropanol is 120ml), and vacuum dried at room temperature for 8h to obtain ethanol-substituted two-dimensional layered germane. UV-Visible-NIR DRS) test shows that its band gap is around 1.81eV.

example 2

[0024] Weigh 200mg (0.001mol) CaGe 2 , dispersed in 30ml of acetonitrile, protected by argon, added 162ul (0.009mol) of ultrapure water, added 2.6ml (0.03mol) of iodoethanol under dark conditions, and stirred and reacted in a constant temperature water bath at a speed of 400r / min at room temperature 7 days. The product was washed with 80 ml of deionized water, then suction-filtered, and washed repeatedly three times (a total of 240 ml of deionized water was used). Then wash with isopropanol three times in the same manner (240 ml of isopropanol), and vacuum-dry at room temperature for 14 h to obtain ethanol-substituted two-dimensional layered germane. UV-Visible-NIR DRS) test shows that its band gap is around 1.81eV.

example 3

[0026] Weigh 300mg (0.0016mol) CaGe 2 , dispersed in 60ml of acetonitrile, nitrogen protection, add 346ul (0.0192mol) ultrapure water, add 6.1ml (0.064mol) iodopropanol under dark conditions, stir the reaction in a constant temperature water bath at 600r / min at room temperature 9 days. The product was washed with 150 ml of deionized water, then suction filtered, and washed three times (450 ml of deionized water in total). Then, it was washed three times with isopropanol in the same manner (the amount of isopropanol was 450 ml), and vacuum-dried at room temperature for 20 h to obtain a two-dimensional layered germane substituted with propanol. UV-Visible-NIR DRS) test shows that its band gap is around 1.89eV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com