A kind of whole cellulose composite material and preparation method thereof

A composite material and whole cellulose technology, which is applied in the field of full cellulose composite materials and its preparation, can solve the problems of lack of thermoplasticity and unsuitability for bioplastic products, and achieve the effect of improving interface compatibility and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to illustrate the content of the present invention more clearly, specific examples are used to illustrate the following, and the specific examples do not limit the scope of the content of the present invention.

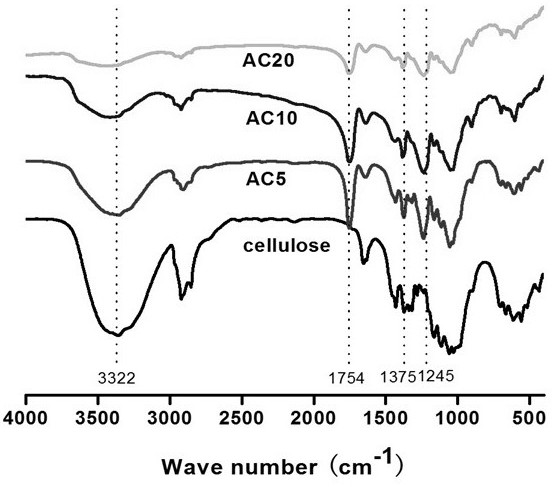

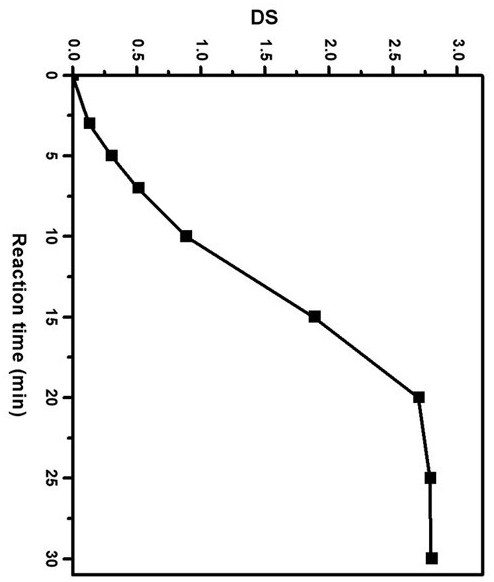

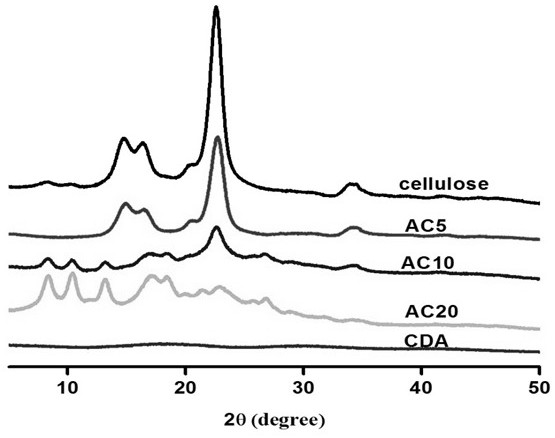

[0020] Because the mechanical properties of this cellulose composite mainly depend on the degree of acetylation substitution, crystal structure, morphology and so on of the added cellulose. Focus on optimizing the preparation process of acetylated cellulose, and adjust the degree of substitution of acetylation of cellulose and the crystallinity of cellulose itself by controlling the time for the preparation of acetylated cellulose catalyzed by iodine, so that cellulose acetate can be improved with acetic acid through acetylation The compatibility of cellulose can ensure sufficient mechanical strength. Finally, the mechanical properties of thermoplastic cellulose are significantly improved.

[0021] Preparation of semi-crystalline acetylated derivative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of acetylation | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com