Deodorizing agent for regenerated rubber as well as preparation method and application thereof

A technology of recycled rubber and deodorant, applied in the field of composite materials, can solve the problems of waste rubber polluting the environment, limiting the production and application range of recycled rubber, and shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

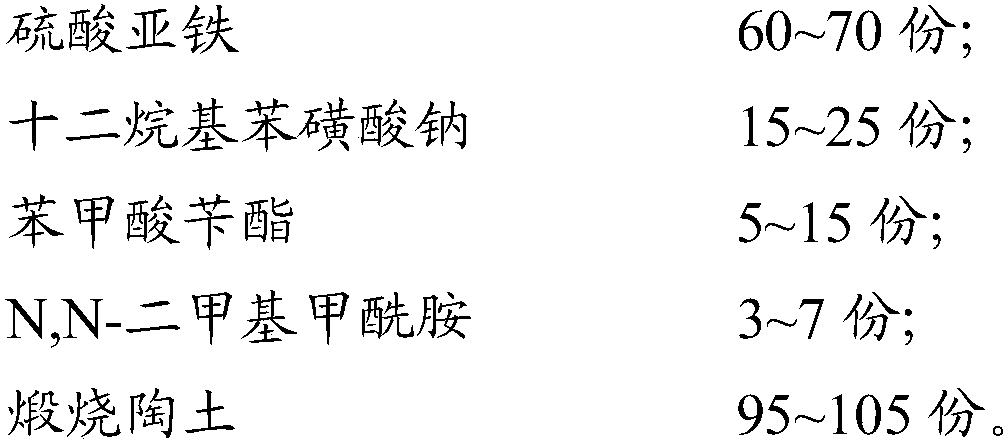

Examples

preparation example Construction

[0031] The present invention provides a preparation method for a deodorant for regenerated rubber described in the above technical solution, comprising the following steps:

[0032] (1) mixing benzyl benzoate and N,N-dimethylformamide to obtain a compound solution;

[0033] (2) Ferrous sulfate, sodium dodecylbenzenesulfonate and calcined clay are mixed to obtain a mixed powder;

[0034] (3) mixing the composite liquid of the step (1) with the mixing powder of the step (2) to obtain a deodorant for regenerated rubber

[0035] The steps (1) and (2) are not in chronological order.

[0036] The invention mixes benzyl benzoate and N,N-dimethylformamide to obtain a complex solution. The present invention has no special requirements on the mixing method, and a mixing method well known to those skilled in the art can be used. In the present invention, it is preferred to mix without stirring. Since the surface tension of benzyl benzoate is 44.0 dyn / cm and that of N,N-dimethylformami...

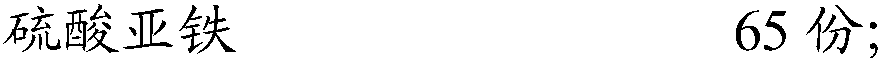

Embodiment 1

[0046] In parts by mass, put 10 parts of benzyl benzoate and 5 parts of N,N-dimethylformamide, a total of 7.5g, into a container and mix to obtain a compound solution;

[0047] Put 65 parts of ferrous sulfate heptahydrate, 20 parts of sodium dodecylbenzenesulfonate, and 100 parts of calcined clay, a total of 92.5g, into the mixer, and stir for 5 minutes to obtain a mixed powder;

[0048] Pour the composite liquid onto the mixed powder in the blender, stir for 5 minutes, release the deodorant used for regenerated rubber, and set aside.

[0049] Mix the waste rubber to be treated, water, softener, activator and prepared deodorant for regenerated rubber, control the amount of deodorant used for regenerated rubber to be 3‰ of the quality of waste rubber, and carry out desulfurization reaction, The regenerated rubber is obtained, and no irritating odor is produced during the rubber regeneration process, and the production environment has passed the acceptance of the environmental p...

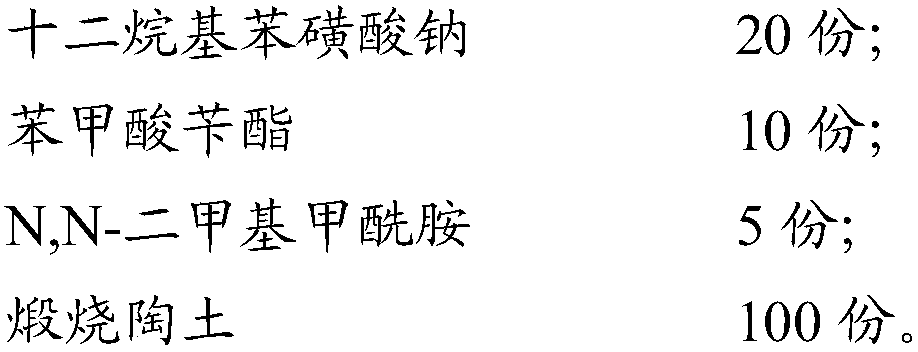

Embodiment 2

[0051] In parts by mass, 5 parts of benzyl benzoate and 4 parts of N,N-dimethylformamide, a total of 9 g, were put into a container and mixed to obtain a composite solution;

[0052] Put 60 parts of ferrous sulfate heptahydrate, 16 parts of sodium dodecylbenzenesulfonate, and 103 parts of calcined pottery clay, a total of 179g, into a blender, and stir for 4 minutes to obtain a mixed powder;

[0053] Pour the composite liquid onto the mixed powder in the blender, stir for 6 minutes, and release the deodorant used for regenerated rubber.

[0054] Mix the waste rubber to be treated, water, softener, activator and prepared deodorant for regenerated rubber, control the amount of deodorant used for regenerated rubber to be 2.5‰ of the quality of waste rubber, and carry out desulfurization reaction. A deodorant for regenerated rubber is obtained, no irritating odor is produced during the rubber regenerated process, and the production environment has passed the inspection and accepta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com