Method for preparing oil needle coke raw material by hydrogenation of aromatic oil

A technology for oil-based needle coke and aromatic oil, which is applied in the treatment of hydrocarbon oil, coking carbonaceous materials, and hydrotreating processes, etc., can solve the problems of high sulfur content and poor quality, and achieve low non-condensable gas yield, Low operating pressure and load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

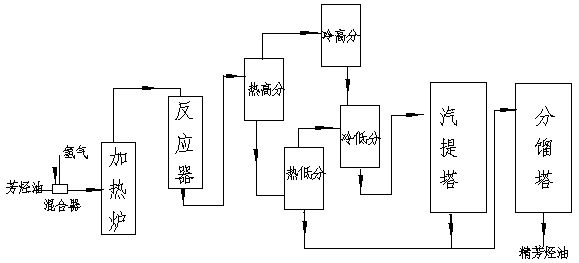

Method used

Image

Examples

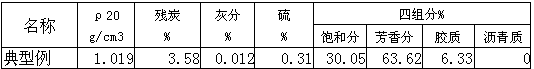

Embodiment 1

[0022] Shandong Yida New Material Co., Ltd. uses the FCC oil slurry (sulfur content of 1.5%) in Shandong District 1 to mix the aromatic oil after the supercritical extraction unit with the hydrogen from the hydrogen production unit in the mixer (mass ratio: 100). :0.8) After being heated to 320℃ through a heating furnace, it enters the aromatic oil hydrogenation reactor (reactor for short). The inlet pressure of the reactor is 7.0MPa. The ratio of cobalt-molybdenum and nickel-molybdenum catalysts in the reactor is 1:3 , Desulfurization and denitrification are carried out in the reactor, the removal rate is over 87%, and the sulfur content is 0.2%. The reaction product flows out from the lower part of the reactor and enters the hot high-separation tank to achieve vapor-liquid separation. After the liquid phase is decompressed, it is sent to the hot low-separation tank for further flash evaporation. The hot low-separation gas phase enters the cold low-separation tank; After press...

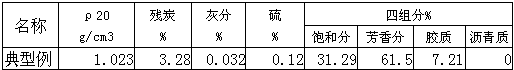

Embodiment 2

[0026] Shandong Yida New Materials Co., Ltd. uses the FCC oil slurry (sulfur content 1.1%) in Northeast Zone 1 to mix the aromatic oil extracted by the supercritical extraction unit with the hydrogen from the hydrogen production unit (mass ratio: 100:0.7) and then heat it The furnace is heated to 280°C and enters the aromatic oil hydrogenation reactor (reactor for short). The inlet pressure of the reactor is 6.0 MPa. The ratio of cobalt-molybdenum and nickel-molybdenum catalysts in the reactor is 1:3, which is carried out in the reactor. Desulfurization and denitrification, the removal rate is over 68%, and the sulfur content is 0.35%. The reaction product flows out from the lower part of the reactor, and enters the hot high separation tank to achieve vapor-liquid separation. After the liquid phase is decompressed, it is sent to the hot low separation tank for further flash evaporation, and the hot low separation gas enters the cold low separation tank; After pressing, enter th...

Embodiment 3

[0030] Shandong Yida New Material Co., Ltd. uses the FCC slurry (sulfur content of 2%) in Shanghai Zone 2 to mix the aromatic oil extracted by the supercritical extraction unit with the hydrogen from the hydrogen production unit (mass ratio: 100:0.6) and then heat it The furnace is heated to 280°C and enters the aromatic oil hydrogenation reactor (reactor for short). The inlet pressure of the reactor is 5.0MPa. The ratio of cobalt-molybdenum and nickel-molybdenum catalysts in the reactor is 2:3, which is carried out in the reactor. Desulfurization and denitrification, the removal rate is over 78%, and the sulfur content is 0.45%. The reaction product flows out from the lower part of the reactor, and enters the hot high separation tank to achieve vapor-liquid separation. After the liquid phase is decompressed, it is sent to the hot low separation tank for further flash evaporation, and the hot low separation gas enters the cold low separation tank; After pressing, enter the frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com