One-step efficient method for preparing cod liver protein and cod liver oil

A technology for cod liver oil and cod liver oil, which is applied to the preparation methods of peptides, chemical instruments and methods, fat oil/fat refining and other directions, can solve the problems of difficult processing, poor quality and complexity of cod liver oil, and achieves improved production efficiency and good product quality. , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

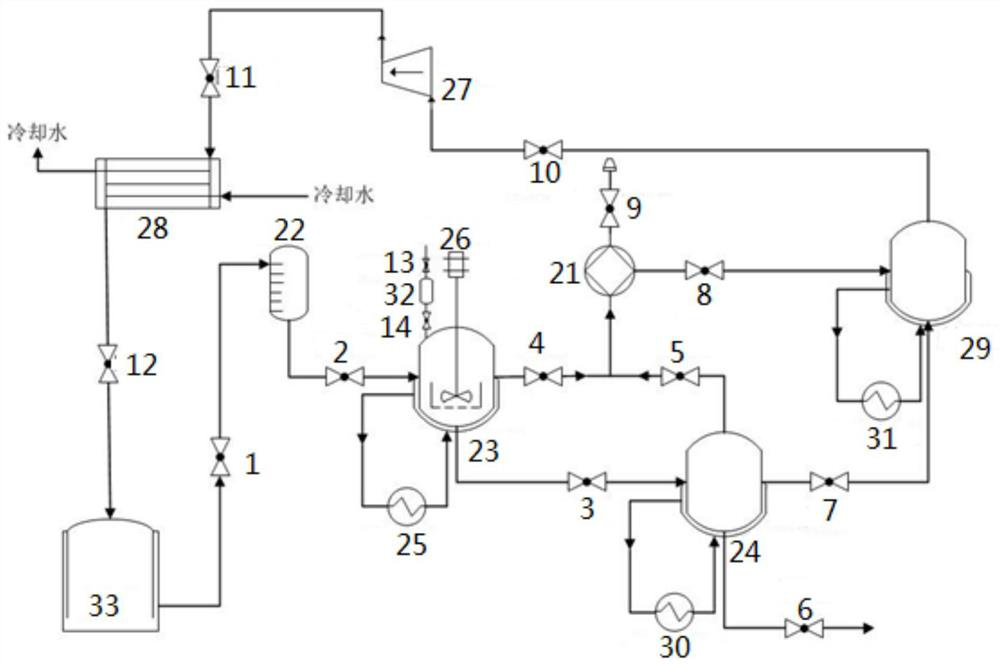

[0047] Such as figure 1 As shown, the extraction device in the present invention includes an extraction part and an extraction agent removal part, and the extraction part includes a liquid storage tank 33, a measuring liquid tank 22, an extraction tank 23, a first circulating hot water 25, an entrainer Tank 32 and mixer 26, the extractant removal part includes a vacuum pump 21, evaporation tank 24, the second circulating hot water 30, buffer tank 29, the third circulating hot water 31, and the extraction device also includes a compressor machine 27 and condenser 28, each component in the extraction device passes through the first valve 1, the second valve 2, the third valve 3, the fourth valve 4, the fifth valve 5, the sixth valve 6, the seventh valve The valve 7, the eighth valve 8, the ninth valve 9, the tenth valve 10, the eleventh valve 11, the twelfth valve 12, the thirteenth valve 13 and the fourteenth valve 14 are connected to each other by pipelines. The structure is ...

Embodiment 2

[0064] Such as figure 1 As shown, the extraction device in the present invention includes an extraction part and an extraction agent removal part, and the extraction part includes a liquid storage tank 33, a measuring liquid tank 22, an extraction tank 23, a first circulating hot water 25, an entrainer Tank 32 and mixer 26, the extractant removal part includes a vacuum pump 21, evaporation tank 24, the second circulating hot water 30, buffer tank 29, the third circulating hot water 31, and the extraction device also includes a compressor machine 27 and condenser 28, each component in the extraction device passes through the first valve 1, the second valve 2, the third valve 3, the fourth valve 4, the fifth valve 5, the sixth valve 6, the seventh valve The valve 7, the eighth valve 8, the ninth valve 9, the tenth valve 10, the eleventh valve 11, the twelfth valve 12, the thirteenth valve 13 and the fourteenth valve 14 are connected to each other by pipelines. The structure is ...

Embodiment 3

[0081] Such as figure 1 As shown, the extraction device in the present invention includes an extraction part and an extraction agent removal part, and the extraction part includes a liquid storage tank 33, a measuring liquid tank 22, an extraction tank 23, a first circulating hot water 25, an entrainer Tank 32 and mixer 26, the extractant removal part includes a vacuum pump 21, evaporation tank 24, the second circulating hot water 30, buffer tank 29, the third circulating hot water 31, and the extraction device also includes a compressor machine 27 and condenser 28, each component in the extraction device passes through the first valve 1, the second valve 2, the third valve 3, the fourth valve 4, the fifth valve 5, the sixth valve 6, the seventh valve The valve 7, the eighth valve 8, the ninth valve 9, the tenth valve 10, the eleventh valve 11, the twelfth valve 12, the thirteenth valve 13 and the fourteenth valve 14 are connected to each other by pipelines. The structure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com