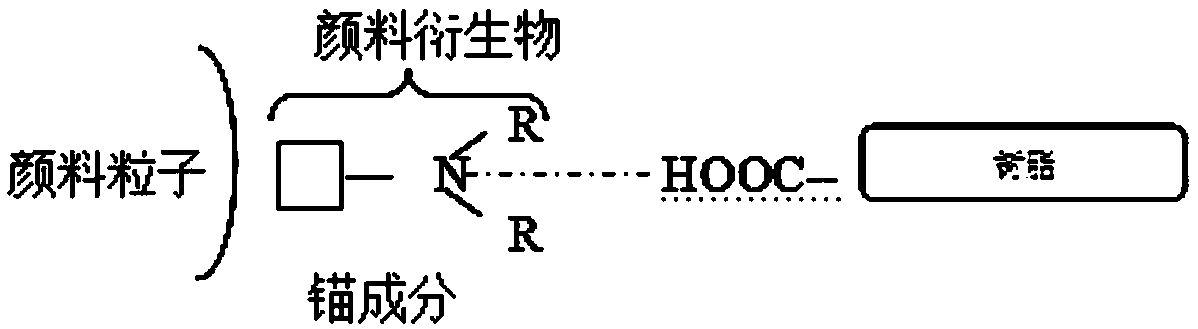

Preparation method of PY138 derivative for liquid crystal display

A technology of liquid crystal display and derivatives, which is applied in the direction of instruments, optics, nonlinear optics, etc., can solve the problems of low affinity of color vehicles, low stimulation activity, and poor dispersion, so as to improve storage stability and improve Quality, improve the effect of product dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

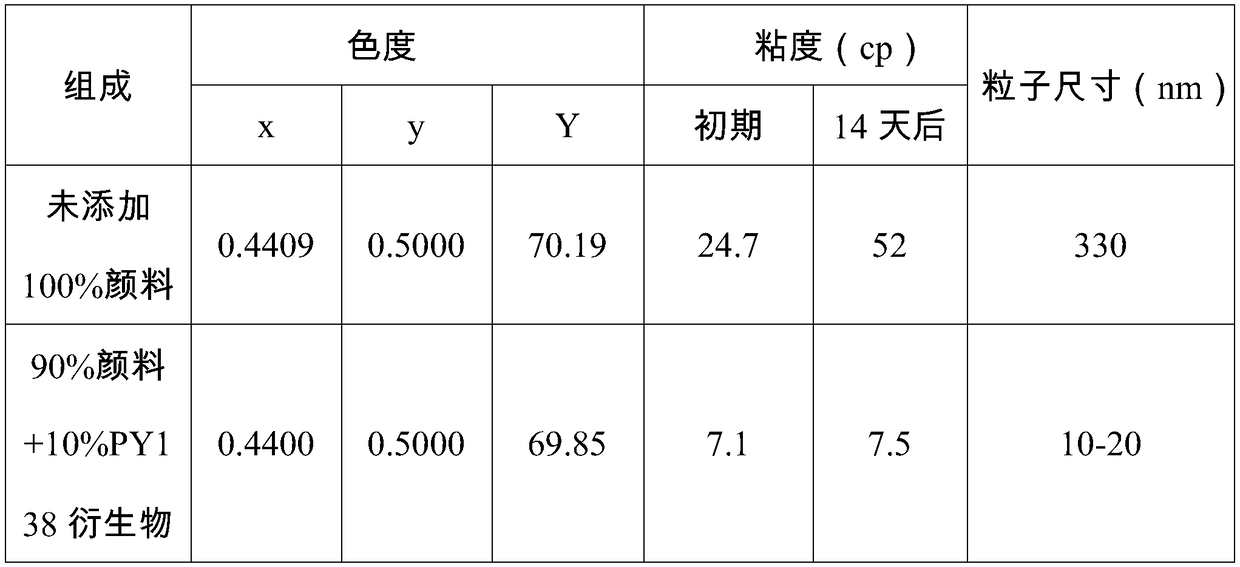

Examples

Embodiment 1

[0027] A preparation method of PY138 derivatives for liquid crystal displays, comprising the following steps:

[0028] (1) at 5m 2 Put 3,500kg of chlorosulfonic acid into the enamel reaction tank and add cold water to cool down to less than 10°C at a speed of 40r / min, then put in 275kg of thionyl chloride and 500kg of crude PY138 in turn, and control the temperature at 25°C, and continue stirring for 12 hours , cooled to 10°C to obtain mixed solution A;

[0029] (2) at 20m 2 Add 5000kg of water and 4000kg of ice to the dilution kettle respectively, control the temperature at 2°C, slowly discharge the mixed liquid A in the enamel reaction tank into the dilution kettle within 100 minutes, control the temperature to less than 12°C, stir for 1 hour while cooling down 5°C to get the diluent;

[0030] (3) Dilute the solution at 160m 2 Press filter in a filter press, add 1% hydrochloric acid at a temperature of 5°C to wash until the pH is 4, and then wash with ice water until neu...

Embodiment 2

[0034] A preparation method of PY138 derivatives for liquid crystal displays, comprising the following steps:

[0035] (1) at 5m 2 Put 3375kg of chlorosulfonic acid into the enamel reaction tank and add cold water to cool down to less than 10°C at a speed of 40r / min, then put in 250kg of thionyl chloride and 450kg of crude PY138 in turn, and control the temperature at 30°C, and continue stirring for 12 hours , cooled to 10°C to obtain mixed solution A;

[0036] (2) at 20m 2 Add 4500kg of water and 4600kg of ice to the dilution kettle, control the temperature at 0°C, slowly discharge the mixed solution A in the enamel reaction tank into the dilution kettle within 160 minutes, control the temperature to less than 12°C, stir for 1 hour while cooling down 0°C to get the diluent;

[0037] (3) Dilute the solution at 160m 2 Filtering in a filter press, adding 1% hydrochloric acid at a temperature of 0°C to wash until the pH is 5, and then washing with ice water until neutral to o...

Embodiment 3

[0041] A preparation method of PY138 derivatives for liquid crystal displays, comprising the following steps:

[0042] (1) at 5m 2 Put 3625kg of chlorosulfonic acid into the enamel reaction tank and add cold water to cool down to less than 10°C at a speed of 40r / min, then put in 300kg of thionyl chloride and 550kg of crude PY138 in turn, and control the temperature at 27°C, and continue stirring for 12 hours , cooled to 10°C to obtain mixed solution A;

[0043] (2) at 20m 2 Add 5500kg of water and 4400kg of ice to the dilution kettle, control the temperature at 1°C, slowly discharge the mixed solution A in the enamel reaction tank into the dilution kettle within 140 minutes, control the temperature to less than 12°C, stir for 1 hour while cooling down 3°C to get the diluent;

[0044] (3) Dilute the solution at 160m 2 Filtering in a filter press, adding 1% hydrochloric acid at a temperature of 2°C to wash until the pH is 5, and then washing with ice water until neutral to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com