Reactor pressure vessel integral top cover with inner platform

A technology for pressure vessels and reactors, applied in reactors, greenhouse gas reduction, nuclear power generation, etc., can solve problems such as out-of-tolerance verticality of tube sockets, achieve weld seam elimination, good shielding effect, and control tube socket position and verticality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The implementation structure of the present invention is:

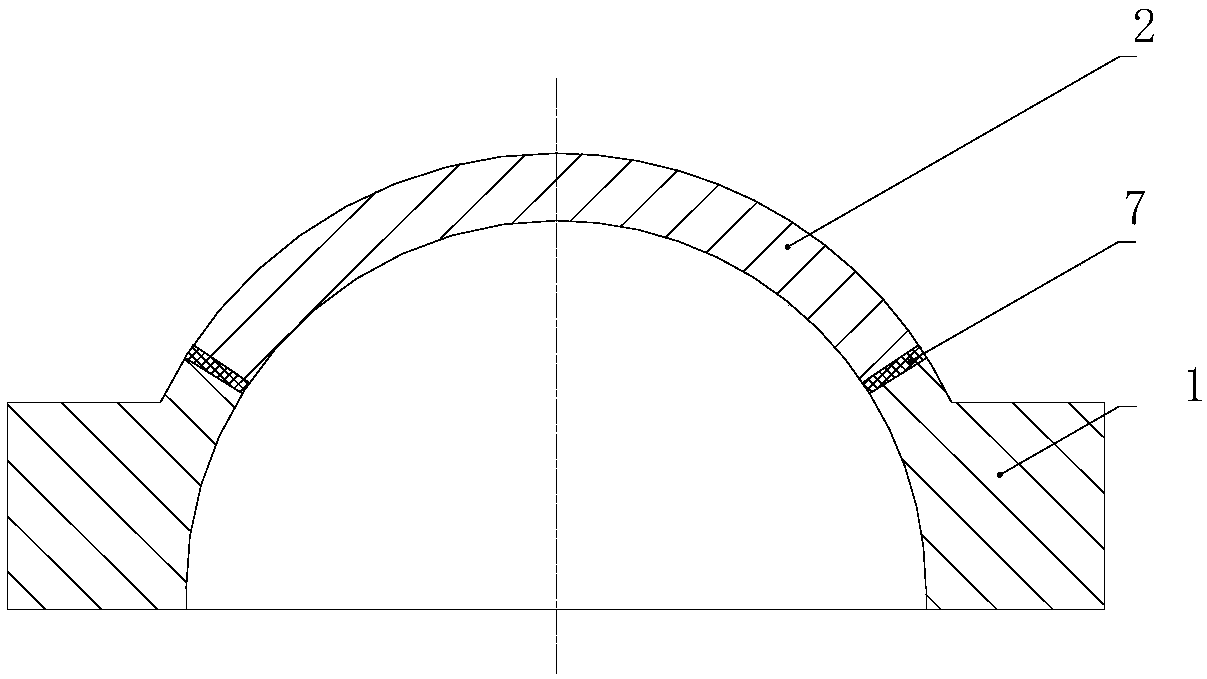

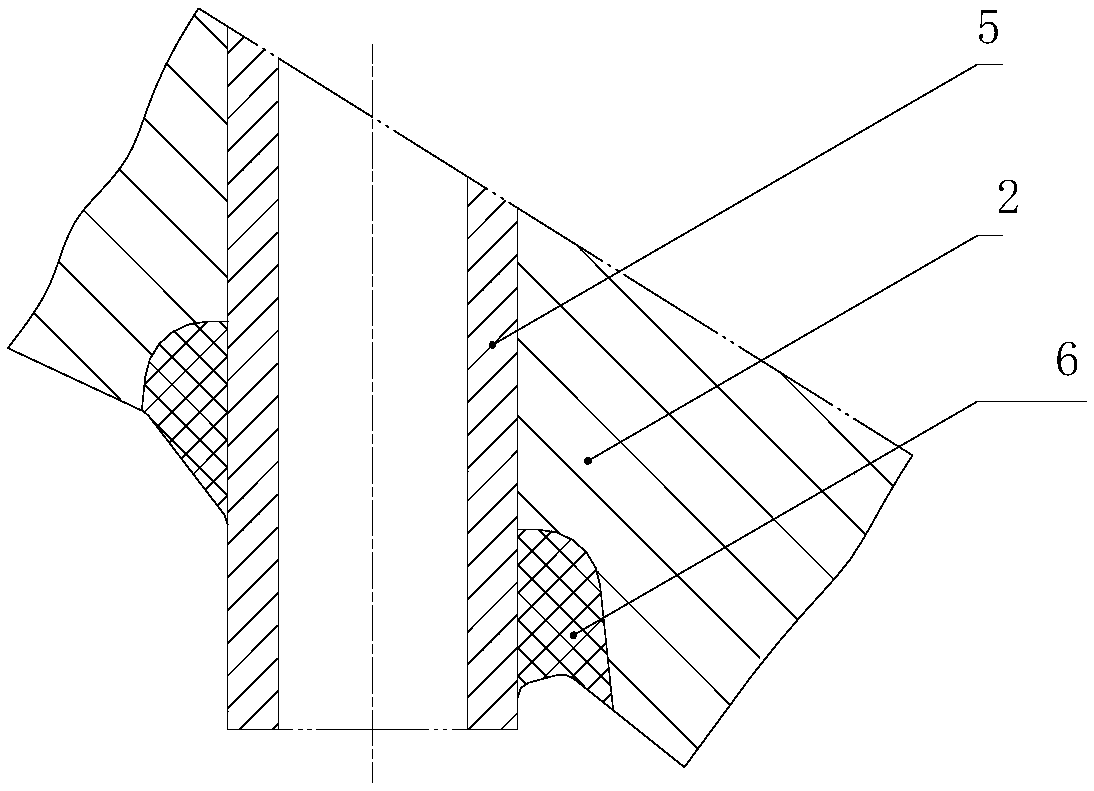

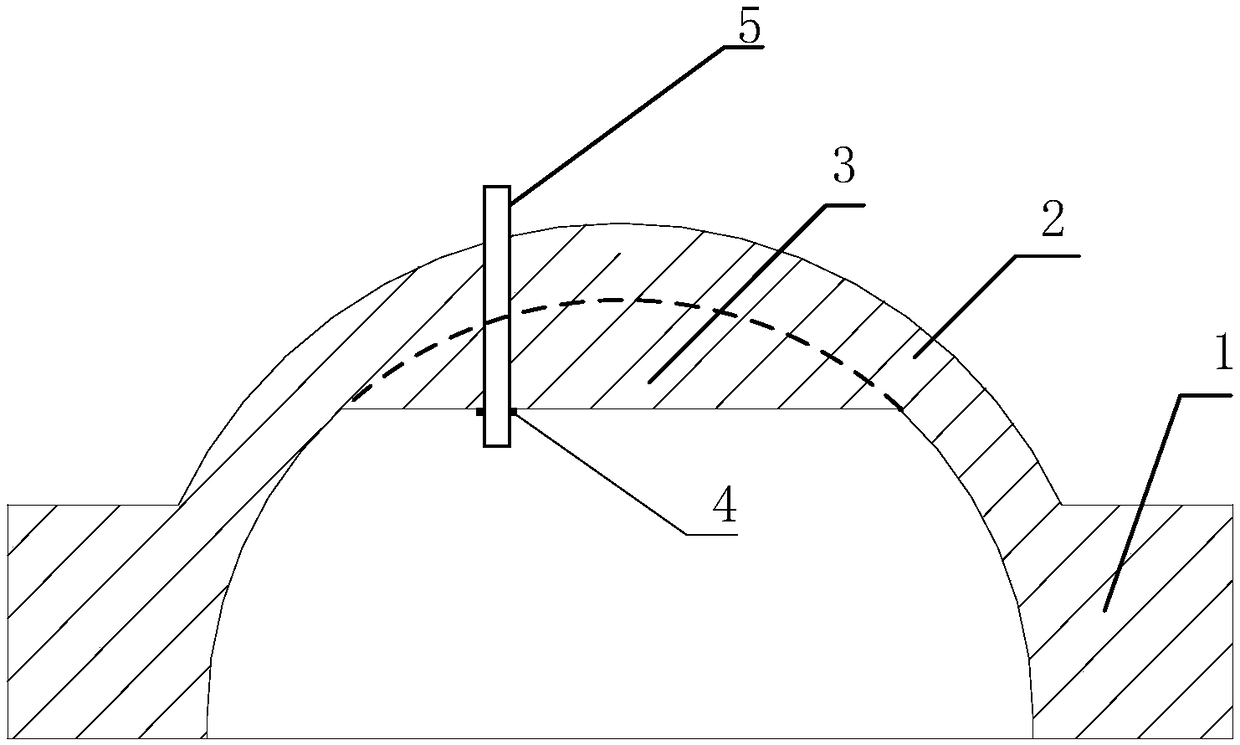

[0034] An integral top cover of a reactor pressure vessel with an inner platform, including an integrated flange 1 and a spherical head 2, and a platform structure 3 is integrally forged on the concave spherical surface of the spherical head, so that the spherical head 2 The concave spherical surface gradually changes from a continuously changing arc surface to a plane and then gradually changes to a continuously changing arc surface. The platform structure 3 is a solid body enclosed by a spherical surface and a circular plane. The spherical surface of the platform structure 3 and the spherical surface The concave spherical surface of the head is integrally matched and connected, and the circular plane of the platform structure 3 is set horizontally, and the height of the circular plane in the vertical direction is higher than the height of the upper end surface of the flange in the vertical direction, and also ...

Embodiment 2

[0046] In this embodiment, on the basis of Example 1, the thickness of the weld seam of the pipe seat is selected to be 2 to 5 mm, the diameter of the weld seam of the pipe seat is 2-5 mm, and the diameter size is the outer diameter size and the inner diameter size Difference. With this size, the welding stress of the weld seam is small, so it can well solve the problem that the position and verticality of the pipe seat after welding are easy to be out of tolerance. And as figure 1 , figure 2 The size of the special-shaped asymmetric weld is generally more than 10mm in diameter, and the depth (thickness of the weld) is more than 20mm. The welding stress of this weld is very large, and it is very difficult to weld. It is easy to be out of tolerance.

Embodiment 3

[0048] Although a platform structure is formed, the continuous gradual arc of the spherical head is not continuously gradual, which will cause a discontinuous inflection point platform structure of the material, that is, the difference between the circular plane and the remaining continuous arc surfaces of the spherical head The junction will form a discontinuous inflection point of the material, which will affect the compressive performance of the entire structure to a certain extent. However, the present invention effectively reduces the weld seam of the pipe seat through the above-mentioned platform structure, and at the same time improves the verticality of the pipe seat. In this case, when the tube base is under pressure, the force from all directions is uniform, so it will promote the uniform pressure of the entire top cover, so it can make up for the above-mentioned compression resistance. In order to reduce the impact caused by the discontinuous inflection point of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com