Method for fabricating flat free contact surfaces of semiconductor nanostructures

A nanostructure and semiconductor technology, which is applied in the field of vertically stacking multiple nanostructures and nanowires, can solve problems such as inability to realize applications, achieve effective controllability, and achieve the effect of vertical integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

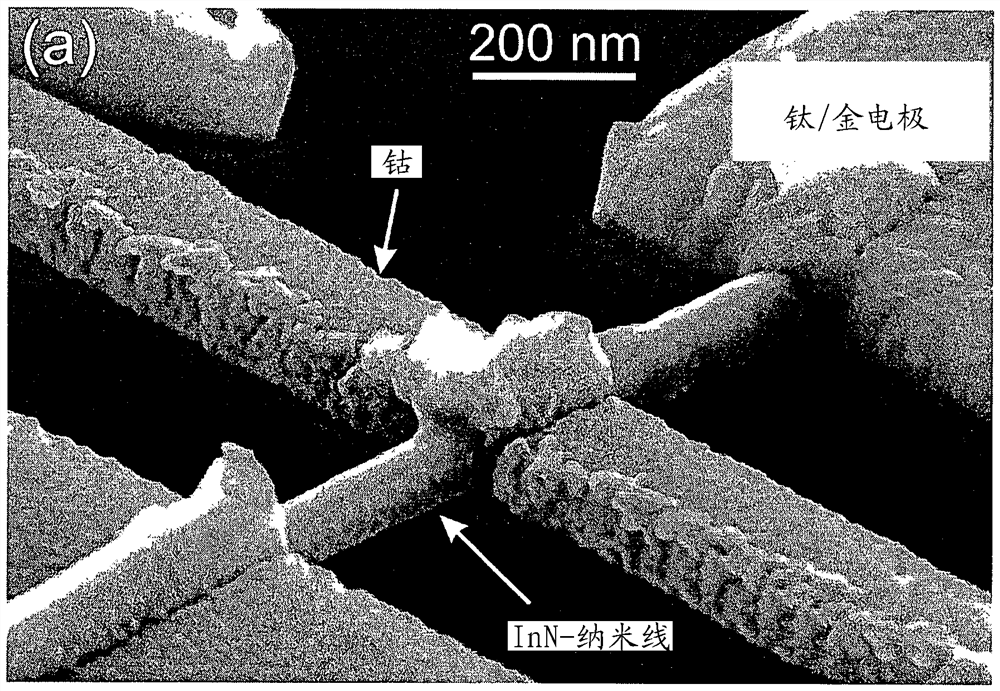

[0078] An unfavorable result that often occurs in conventionally evaporated nanowires with thin metal layers is identified in Fig. 1(a) with interruptions in the electrical contacts due to shadowing effects. In particular, ferromagnetic contacts, for example composed of cobalt, have a significant disturbance of the homogeneity of the magnetization, which is mandatory for several components of spintronics and is shown in Fig. 1(b) .

[0079] In Fig. 1(b), the calculated local magnetization is shown in cross-section along the cobalt contact surrounding this circular Nanowire cross-sections are laid. Here, the stated external magnetic field is applied along the main axis of the cobalt strip, ie perpendicular to the nanowire and parallel to the substrate.

[0080] Arrows inside cobalt contacts: local orientation of magnetic moments;

[0081] Highlighted in grey: localized magnetization points mostly to the right

[0082] Bright area: localized magnetization points mostly to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com