Structural antibacterial polyurethane flexible foam material and preparation method thereof

A polyurethane soft foam and polyol technology, which is applied in the field of polyurethane foam, can solve the problems of large dosage, non-environmental protection, discoloration, etc., and achieve the effects of good antibacterial performance, stable performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

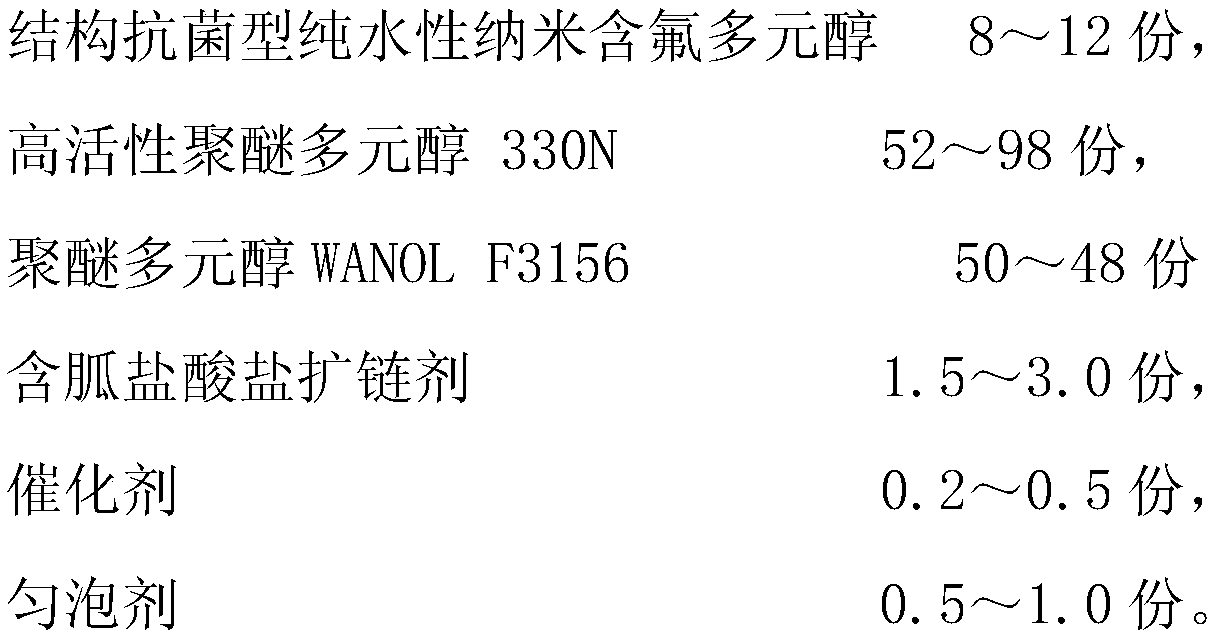

[0042] (1), in parts by weight, 10 parts of structure antibacterial type pure water-based nano fluorine-containing polyols, 50 parts of highly active polyether polyols 330N, 50 parts of polyether polyols WANOL F3156, 2.0 parts of guanidine-containing hydrochloric acid Add salt chain extender, 0.3 part of dibutyltin dilaurate and 1.0 part of silicone oil into a tetrafluoroethylene container with a volume of 1L, control the speed at 5000rmp, and stir at room temperature for 30s to obtain a structural antibacterial polyurethane soft foam material A components.

[0043] (2) Take the A component obtained in the above step (1) and 55.6 parts of TDI, put it in a polytetrafluoroethylene container, control the rotation speed at 5000rmp, stir at room temperature for 20s, and pour it into a self-made 20cm×10cm×10cm polytetrafluoroethylene mold Curing in medium for 110s, curing at room temperature for 36h, a structural antibacterial polyurethane soft foam material is obtained.

[0044] A...

Embodiment 2

[0046] (1), in parts by weight, 10 parts of structure antibacterial type pure water-based nano fluorine-containing polyols, 40 parts of highly active polyether polyols 330N, 60 parts of polyether polyols WANOL F3156, 2.0 parts of guanidine-containing hydrochloric acid Add salt chain extender, 0.4 parts of stannous octoate and 1.0 parts of silicone oil into a tetrafluoroethylene container with a volume of 1L, control the rotation speed at 5000rmp, stir at room temperature for 30s, and obtain a component A of a structural antibacterial polyurethane soft foam material .

[0047](2) Take the A component obtained in the above step (1), 35.4 parts of TDI, and 23.6 parts of MDI, put it in a polytetrafluoroethylene container, control the rotation speed at 5000rmp, stir at room temperature for 15s, and pour it into a homemade 20cm×10cm×10cm poly Curing in a tetrafluoroethylene mold for 110 seconds, and curing at room temperature for 36 hours, a structural antibacterial polyurethane sof...

Embodiment 3

[0050] (1), in parts by weight, 8 parts of structure antibacterial type pure water-based nano fluorine-containing polyols, 42 parts of highly active polyether polyols 330N, 60 parts of polyether polyols WANOL F3156, 3.0 parts of guanidine-containing hydrochloric acid Add salt chain extender, 0.2 parts of dibutyltin dilaurate, 0.3 parts of triethylenediamine and 0.5 parts of silicone oil into a tetrafluoroethylene container with a volume of 1L, control the speed at 5000rmp, and stir at room temperature for 30s to obtain a structure Component A of antibacterial polyurethane soft foam material.

[0051] (2) Take the A component obtained in the above step (1) and 55.6 parts of TDI, put it in a polytetrafluoroethylene container, control the rotation speed at 5000rmp, stir at room temperature for 30s, and pour it into a homemade 20cm×10cm×10cm polytetrafluoroethylene mold Curing in medium for 110s, curing at room temperature for 36h, a structural antibacterial polyurethane soft foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com