Method for increasing crystallization ratio of crystallized malt

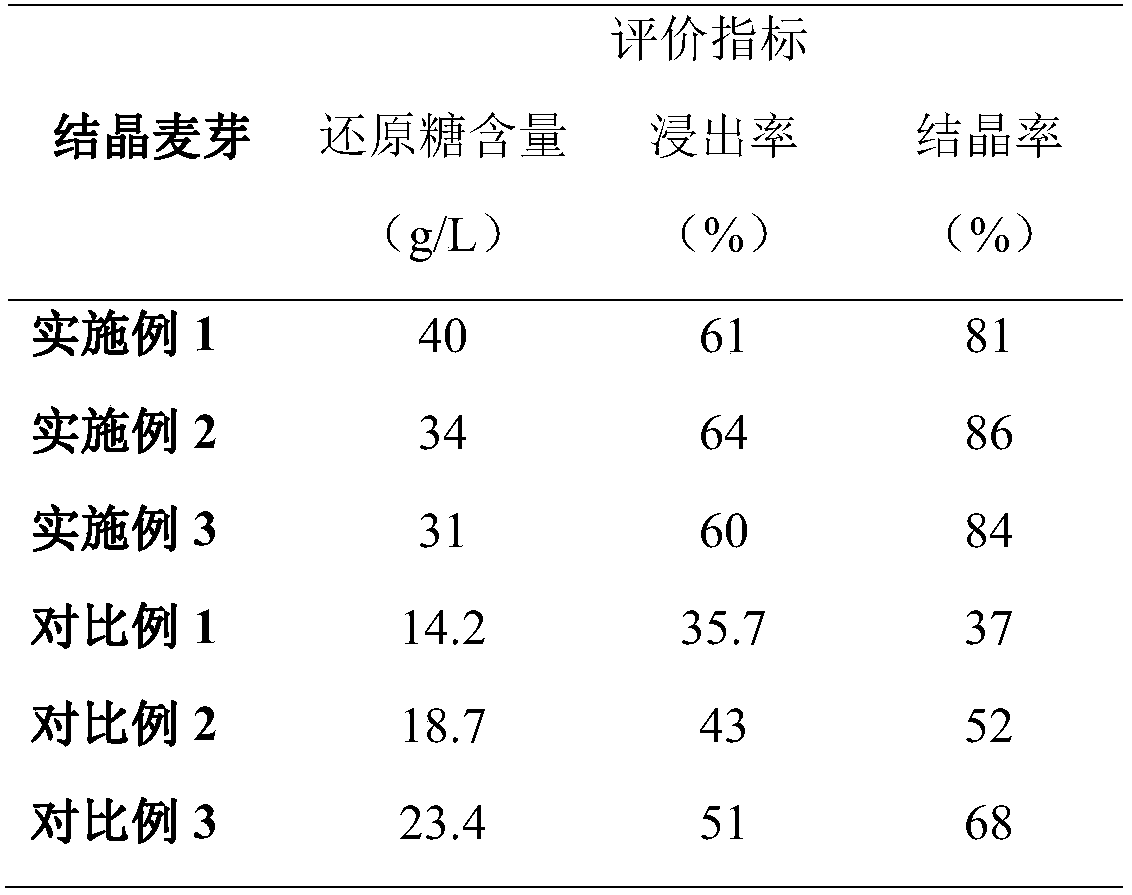

A technology of crystallization rate and malt, which is applied in the field of increasing the crystallization rate of crystallized malt, can solve the problems of low crystallization rate of crystallized malt, achieve high reducing sugar content, high leaching rate, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Wheat washing: Weigh 200g of impurity-removed barley, wash the barley 3 times, let stand for 10 minutes each time, and then change the water.

[0029] (2) Wheat immersion: at 14°C, soak wheat for 6 hours for the first time, cut off water for 8 hours for the first time; soak wheat for 4 hours for the second time; cut off water for 6 hours for the second time; soak wheat for 3 hours for the third time.

[0030] (3) Germination: During the germination stage, water needs to be replenished many times, and the germination lasts for 4 days.

[0031] (4) Protein decomposition: Soak the green malt in water, and heat it at 40°C for 40 minutes with an electric heating constant temperature water tank.

[0032] (5) Saccharification: continue to soak the green malt in water, raise the temperature to 70°C and keep it for 2 hours.

[0033] (6) Drying: Take the saccharified green malt out of the water, drain, and dry at 85°C for 30 minutes.

[0034] (7) Scorching: Put the malt int...

Embodiment 2

[0038] (1) Wheat washing: Weigh 200g of impurity-removed barley, wash the barley twice with water, let stand for 10 minutes each time, and then change the water.

[0039] (2) Soak wheat: at 14°C, soak wheat for 6 hours for the first time, cut off water for 8 hours for the first time, soak for 4 hours for the second time, cut off water for 6 hours for the second time, and soak for 3 hours for the third time.

[0040] (3) Germination: During the germination stage, water needs to be replenished many times, and the germination lasts for 4 days.

[0041] (4) Proteolysis: Soak the green malt in water, and heat it at 50°C for 40 minutes with an electric heating constant temperature water tank.

[0042] (5) Saccharification: continue to soak the green malt in water, raise the temperature to 65°C and keep it for 2 hours.

[0043] (6) Drying: The saccharified green malt is taken out of the water, drained, and dried at 95°C for 30 minutes.

[0044] (7) Scorching: put the malt into an e...

Embodiment 3

[0048] (1) Wheat washing: Weigh 200g of impurity-removed barley, wash the barley twice with water, let stand for 10 minutes each time, and then change the water.

[0049] (2) Soak wheat: at 15°C, soak wheat for 6 hours for the first time, cut off water for 8 hours for the first time, soak for 4 hours for the second time, cut off water for 6 hours for the second time, and soak for 3 hours for the third time.

[0050] (3) Germination: During the germination stage, water needs to be replenished many times, and the germination lasts for 4 days.

[0051] (4) Proteolysis: Soak the green malt in water, and heat it at 50°C for 40 minutes with an electric heating constant temperature water tank.

[0052] (5) Saccharification: continue to soak the green malt in water, raise the temperature to 60°C and keep it for 2 hours.

[0053] (6) Drying: The saccharified green malt is taken out of the water, drained, and dried at 95°C for 30 minutes.

[0054] (7) Burning: put the malt into an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com