Pretreatment method for improving saccharification efficiency of rape stalks

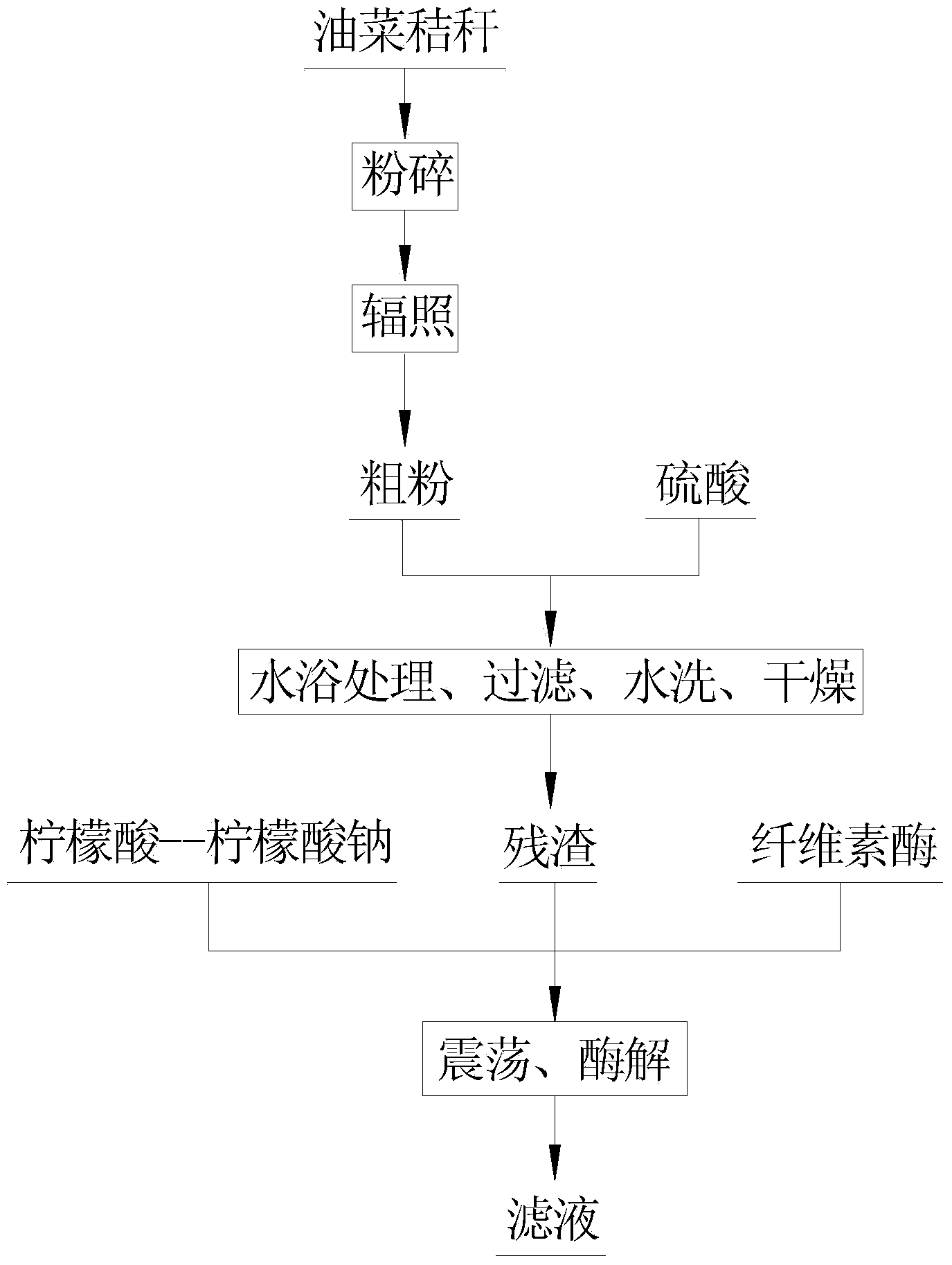

A technology of rape straw and saccharification rate, which is applied in biosynthesis, biofuel, fermentation, etc., can solve the problems of cellulose and hemicellulose consumption, the impact of fermentation process, serious environmental pollution, etc., and achieve the reduction of crystallinity and low equipment requirements , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The air-dried rape stalks were coarsely chopped and crushed to 30-mesh powder, put into a 1000mL white glass bottle, and subjected to 60 Co-γ-ray irradiation, the dose is 800kGy, irradiated at natural room temperature, the radiation cobalt source intensity is 9.99×10 15 Bq, dose rate 2kGy / h. All irradiation pretreatment experiments were conducted in the Hunan Provincial Irradiation Center 60 Co-γ-ray irradiation device completed. Take 1 gram of the above irradiated powder, add 0.5% sulfuric acid solution according to the solid-to-liquid ratio of 1:20, stir evenly, treat in a water bath at 80°C for 1.5 hours, cool and filter, wash the residue with water until it is neutral, and then dry it at 50°C; Take 1 gram of the dried residue and add it to the citric acid-sodium citrate buffer solution with pH 5.0 at a solid-to-liquid ratio of 1:25, then add Novozymes cellulase 225FPU / g, shake at 50°C and 150rpm, and perform enzymatic hydrolysis for 72 Hours, the measured reducin...

Embodiment 2

[0032] The air-dried rape stalks were roughly chopped and crushed to 20-mesh powder, put into a 1000mL white glass bottle, and subjected to 60 Co-γ-ray irradiation, the dose is 1000kGy, irradiated at natural room temperature, the radiation cobalt source intensity is 9.99×10 15 Bq, dose rate 2kGy / h. All irradiation pretreatment experiments were conducted in the Hunan Provincial Irradiation Center 60 Co-γ-ray irradiation device completed. Take 1 gram of the above irradiated powder, add 1.1% sulfuric acid solution at a solid-to-liquid ratio of 1:15, stir evenly, treat in a water bath at 90°C for 2.0 hours, cool and filter, wash the residue with water until it is neutral, and then dry it at 60°C; Take 1 gram of the dried residue and add it to the citric acid-sodium citrate buffer solution with pH 4.8 at a solid-to-liquid ratio of 1:30, then add Novozymes cellulase 250 FPU / g, shake at 55°C and 140 rpm, and enzymatically digest 96 Hours, the measured reducing sugar content reache...

Embodiment 3

[0034] The air-dried rape stalks were coarsely chopped and crushed to 40 mesh powder, put into a 1000mL white glass bottle, and subjected to 60 Co-γ-ray irradiation, the dose is 600kGy, irradiated at natural room temperature, the radiation cobalt source intensity is 9.99×10 15 Bq, dose rate 2kGy / h. All irradiation pretreatment experiments were conducted in the Hunan Provincial Irradiation Center 60 Co-γ-ray irradiation device completed. Take 1 gram of the above irradiated powder, add 2.1% sulfuric acid solution at a solid-to-liquid ratio of 1:10, stir evenly, treat in a water bath at 70°C for 1.0 hour, cool and filter, wash the residue with water until it is neutral, and then dry it at 45°C; Take 1 gram of the dried residue and add it to the citric acid-sodium citrate buffer solution with pH 4.5 at a solid-to-liquid ratio of 1:20, then add Novozymes cellulase 200 FPU / g, shake at 50°C and 145rpm, and perform enzymatic hydrolysis for 48 Hours, the measured reducing sugar cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com