Device and method for obtaining soot particulate breaking characteristic in combustion process

A soot particle and combustion process technology, applied in measuring devices, particle and sedimentation analysis, particle size analysis, etc., to achieve the effects of reducing experimental errors, enriching the oxidation induction mechanism, and improving the oxidation induction mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

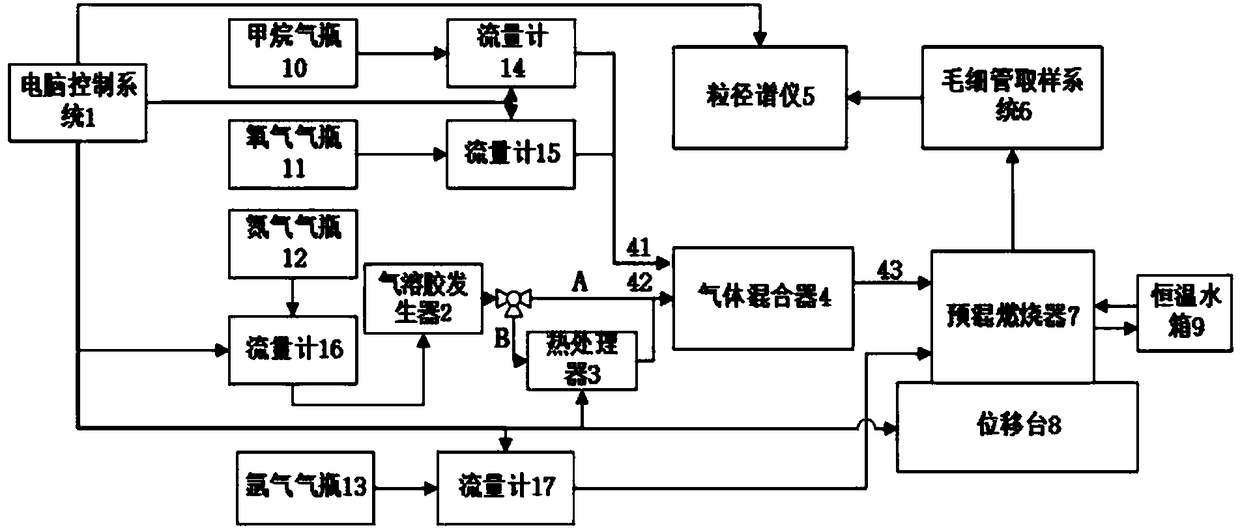

[0022] Such as figure 1 As shown, a device for obtaining the crushing characteristics of soot particles in the combustion process proposed by the present invention includes a computer control system 1, an aerosol generator 2, a heat processor 3, a gas mixer 4, a particle size spectrometer 5, and capillary sampling System 6, premix burner 7, stage 8 and constant temperature water tank 9.

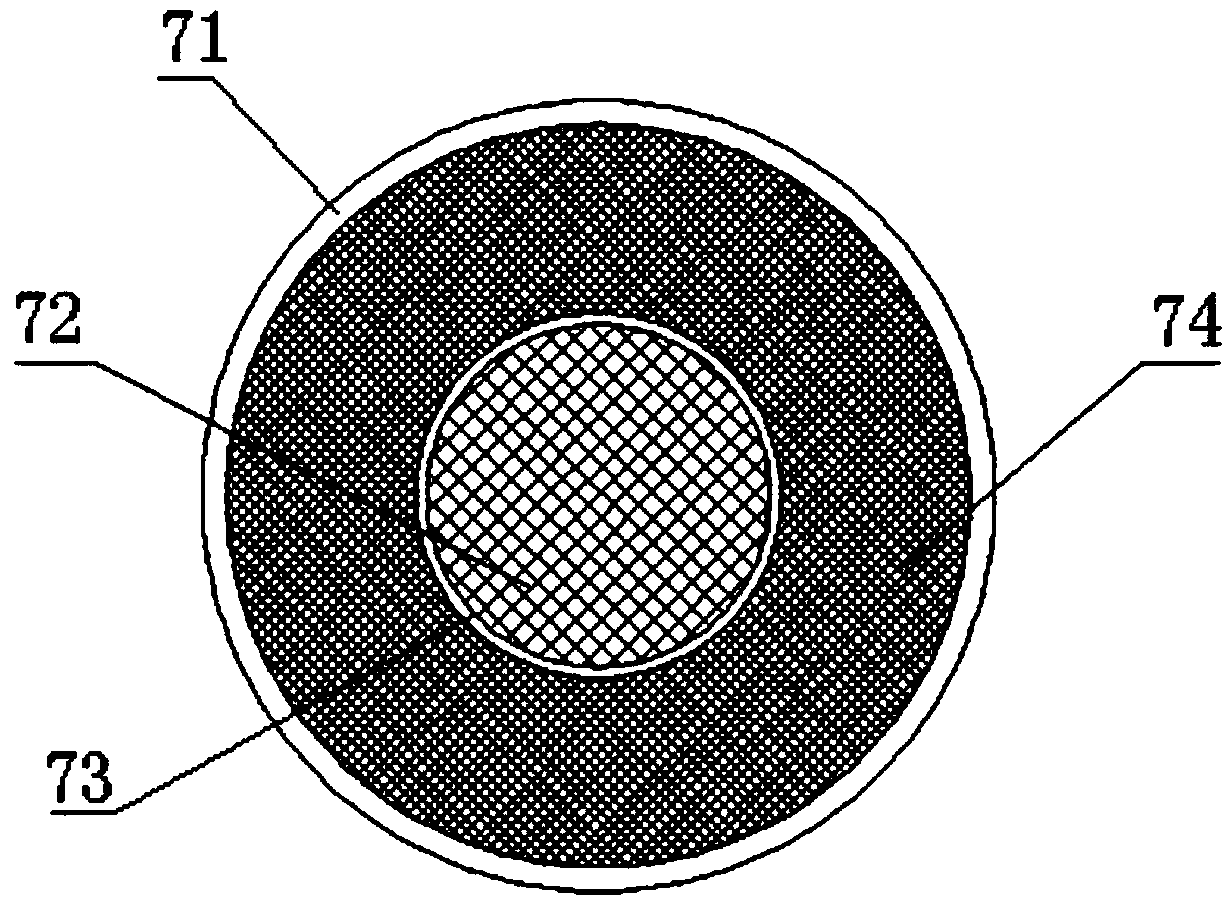

[0023] The premix burner 7 includes a cylindrical main body 71, and a coil is arranged in the main body 71, and the coil is connected to the constant temperature water tank 9 to keep the temperature of the mixed gas constant; the outer diameter of the main body 71 65mm, such as image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com