Preparation method of functional graphene oxide sponge

A graphene sponge, a functional technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as poor water solubility, environmental pollution, etc., and achieve large surface area, hypermolecular recognition and The effect of enrichment capacity

Inactive Publication Date: 2018-12-28

EAST CHINA UNIV OF TECH

View PDF1 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the poor water solubility of most calixarenes, they are often used in organic solvents such as toluene, chloroform, methylene chloride, etc. when applying calixarene, which brings environmental pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption | aaaaa | aaaaa |

Login to View More

Abstract

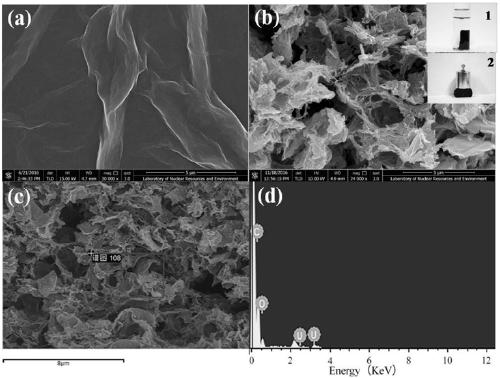

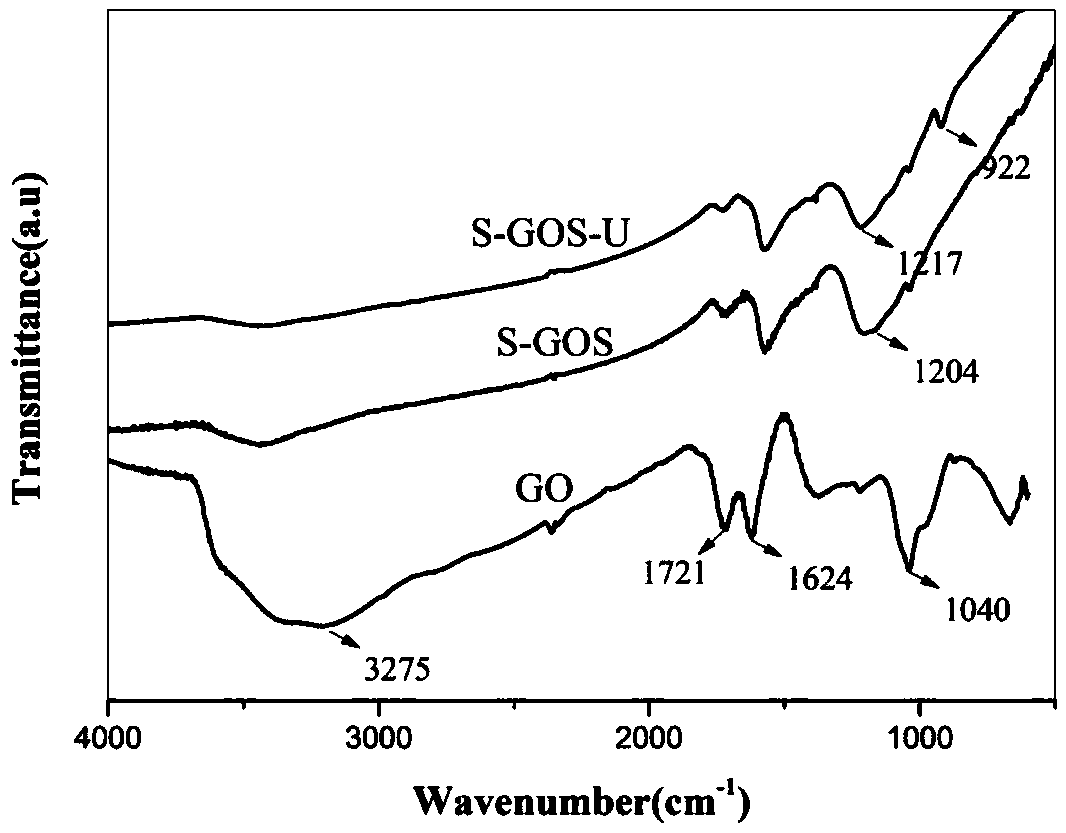

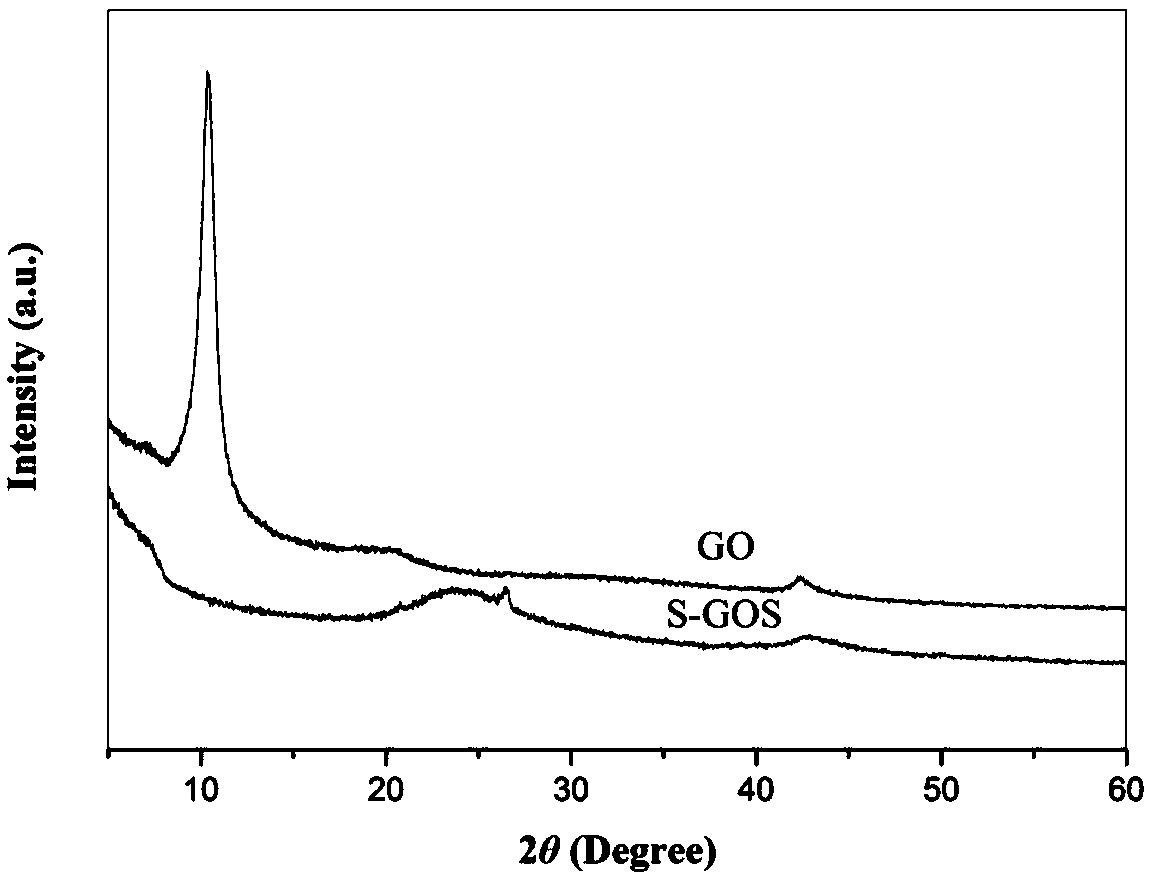

The invention provides a preparation method of a functional graphene oxide sponge. According to the method, sulfonated calix [4] arene and GO (graphene oxide) are synthesized firstly, sulfonated calix[4] arene and GO are subjected to a hydrothermal reaction, grapheme hydrogel is prepared and subjected to freeze drying, and sulfonated calix [4] arene modified 3D S-GOS (stereoscopic-graphene oxidesponge) is obtained. The material is subjected to characterization analysis with analytical means such as SEM, EDS, FT-IR, XRD and the like. With the adoption of a static adsorption method, influenceof pH value, ion strength, adsorption time, initial uranium concentration and temperature of an initial solution on S-GOS adsorbed uranium (VI) is researched, and adsorption kinetics and adsorption thermodynamics of the S-GOS are studied. The regeneration-recycle performance of the S-GOS adsorbed uranium (VI) is investigated finally. The synthesis method is simple, one new material with large superficial area and high supramolecular recognition and enrichment capacity is obtained, and the material is good in adsorptive property, convenient to recycle and excellent in biocompatibility.

Description

technical field The invention belongs to the field of material preparation, and in particular relates to a preparation method of functionalized graphene oxide sponge. Background technique In recent years, graphene, as a two-dimensional material, has attracted great attention from scholars at home and abroad due to its remarkable and unique properties, such as excellent mechanical properties and extremely high specific surface area. There are also extensive researches in the field of adsorption, but two-dimensional graphene-based adsorbents are easy to agglomerate and not easy to recycle during application, which limits their application in the field of adsorption and separation. The three-dimensional graphene-based macroscopic body has a three-dimensional network-like porous structure and large size, has good adsorption performance and is easy to collect and recycle, and has potential applications in wastewater treatment. Calixarenes are considered to be the third-generati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J20/22B01J20/28B01J20/30C02F1/28

CPCB01J20/20B01J20/22B01J20/28045B01J20/3078C02F1/288

Inventor 刘淑娟马建国罗建强张寒雪李松张祎鹏

Owner EAST CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com