Base plate for integral bathroom wall panel and manufacturing method thereof

A technology for substrates and bathrooms, which is applied to the substrates for integral bathroom wall panels and their production fields, can solve the problems of affecting aesthetics, inconvenient installation, low strength, etc., and achieves stable structure without deformation, minimized material consumption, and simple production equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

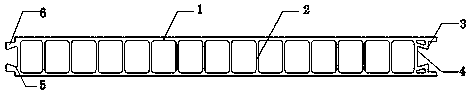

[0048] Raw materials: 100 parts of PVC, 100 parts of calcium carbonate powder, 7 parts of regulator, 4 parts of lead-zinc stabilizer, 0.8 part of foaming agent, 0.45 parts of PE paraffin external lubricant, and 0.5 part of stearic acid internal lubricant.

[0049] Type 65 twin-screw extrusion equipment is used. The finished mold size is 380mm wide, 35mm thick, baffle plate thick 3mm, rib plate thick 2mm, and rib spacing 25mm.

[0050] Production method: heat the above raw materials to 120°C and mix them evenly, then cool and mix them below 45°C at low temperature, put the mixed raw materials into the twin-screw extrusion equipment, heat them to 180°C for extrusion, because the substrate is thicker, In order to prevent uneven deformation of the product when it is cooled, a self-designed vacuum cooling water tank is used for the cold-setting part. The appearance, size and strength of the final product meet the design and use requirements.

[0051] To sum up, the substrate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com