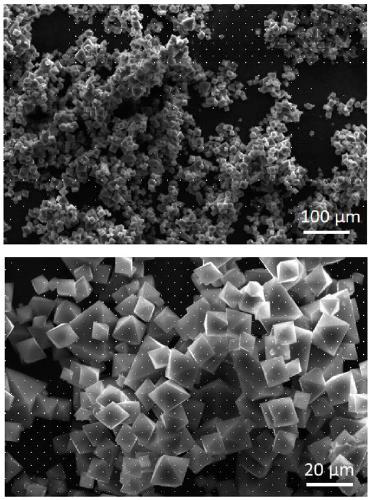

Preparation method of octahedral cuprous oxide micron-crystalline with uniform morphology

A cuprous oxide and octahedral technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of cumbersome and complex process, and achieve the effects of simple production equipment, high product purity and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Preparation of cuprous oxide microcrystals with octahedral uniform morphology according to the following steps

[0020] (1) Set the reaction temperature to 20°C, add boric acid to the copper sulfate aqueous solution with a concentration of 0.01mol / L, and stir to obtain a clear mixed solution;

[0021] (2) Add ascorbic acid to the mixed solution at one time, control the molar ratio of boric acid, divalent copper salt and ascorbic acid to 2:1:2.5, and the whole reaction process is carried out under stirring at 300 rpm; after 60 minutes of reaction, the obtained product Centrifuge, wash, and dry to obtain cuprous oxide microcrystals with octahedral uniform shape.

Embodiment 2

[0022] Example 2: Preparation of cuprous oxide microcrystals with octahedral uniform morphology according to the following steps

[0023] (1) Set the reaction temperature to 30°C, add boric acid to an aqueous copper chloride solution with a concentration of 0.015mol / L, and stir to obtain a clear mixed solution;

[0024] (2) Add ascorbic acid to the mixed solution at one time, and control the molar ratio of boric acid, divalent copper salt and ascorbic acid to 5:1:2.5. The whole reaction process is carried out under stirring at 300 rpm; after 40 minutes of reaction, the obtained product Centrifuge, wash, and dry to obtain cuprous oxide microcrystals with octahedral uniform shape.

Embodiment 3

[0025] Example 3: Preparation of cuprous oxide microcrystals with octahedral uniform morphology according to the following steps

[0026] (1) Set the reaction temperature to 40°C, add boric acid to the copper acetate aqueous solution with a concentration of 0.02 mol / L, and stir to obtain a clear mixed solution;

[0027] (2) Add ascorbic acid to the mixed solution at one time, and control the molar ratio of boric acid, divalent copper salt and ascorbic acid to 8:1:2.5. The whole reaction process is carried out under stirring at 300 rpm; after 20 minutes of reaction, the obtained product is Centrifuge, wash, and dry to obtain cuprous oxide microcrystals with octahedral uniform shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com