Anti-freezing agent for concrete and preparation method of anti-freezing agent

An antifreeze and concrete technology, applied in the field of concrete additives, can solve the problems that the performance of antifreeze products needs to be improved, the performance of antifreeze agent cannot meet the needs of use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

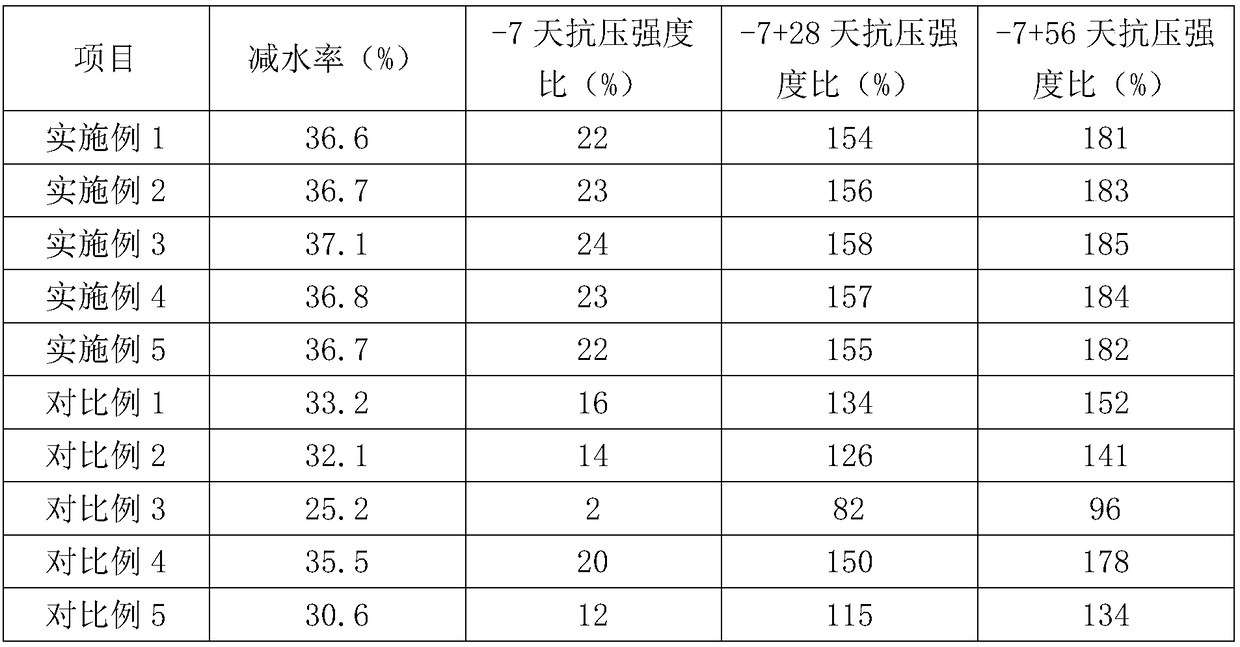

Examples

Embodiment 1

[0020] A concrete antifreeze agent, comprising the following raw materials in parts by weight: 12 parts of methylpentanone alcohol, 8 parts of succinamide, 5.4 parts of mushroom alcohol, 4.6 parts of sodium hexafluorophosphate, 3.8 parts of triisopropanolamine, expanded perlite 2.4 parts, 1.5 parts of N-vinylpyrrolidone;

[0021] The expansion factor of the expanded perlite is 12.

[0022] A preparation method for concrete antifreeze, comprising the following steps:

[0023] (1) Mix expanded perlite and sodium hexafluorophosphate into a stirring heating kettle, heat to 200°C at 400rpm, keep stirring for 1 hour, cool to room temperature after the end, mix with succinamide evenly and perform superfine grinding machine, and pass through a 200-mesh sieve;

[0024] (2) Add the product of step (1) into methyl pentanone alcohol, and soak for 4 hours at minus 20 degrees Celsius;

[0025] (3) Heat the product obtained in step (2) to 40° C., add mushroom alcohol, triisopropanolamine ...

Embodiment 2

[0027] A concrete antifreeze agent, comprising the following raw materials in parts by weight: 14 parts of methyl pentanone alcohol, 9 parts of succinamide, 5.8 parts of mushroom alcohol, 5 parts of sodium hexafluorophosphate, 4 parts of triisopropanolamine, expanded perlite 3 parts, 2 parts of N-vinylpyrrolidone;

[0028] The expansion factor of the expanded perlite is 13.

[0029] A preparation method for concrete antifreeze, comprising the following steps:

[0030] (1) Mix expanded perlite and sodium hexafluorophosphate into a stirring heating kettle, heat to 205°C at 450rpm, keep stirring for 1.2h, cool to room temperature after completion, mix with succinamide evenly, and pass through ultramicro Pulverizer, and pass through 200 mesh sieve;

[0031] (2) Add the product of step (1) into methyl pentanone alcohol and soak for 5 hours at minus 18 degrees Celsius;

[0032] (3) Heat the product obtained in step (2) to 45°C, add mushroom alcohol, triisopropanolamine and N-viny...

Embodiment 3

[0034] A concrete antifreeze agent, comprising the following raw materials in parts by weight: 12 parts of methylpentanone alcohol, 10 parts of succinamide, 6 parts of mushroom alcohol, 5.4 parts of sodium hexafluorophosphate, 5 parts of triisopropanolamine, expanded perlite 3.4 parts, 2.5 parts of N-vinylpyrrolidone;

[0035] The expansion factor of the expanded perlite is 14.

[0036] A preparation method for concrete antifreeze, comprising the following steps:

[0037] (1) Mix expanded perlite and sodium hexafluorophosphate into a stirring heating kettle, heat to 210°C at 500rpm, keep stirring for 1.5h, cool to room temperature after the end, mix with succinamide evenly, and pass through ultramicro Pulverizer, and pass through 200 mesh sieve;

[0038] (2) adding the product of step (1) into methyl pentanone alcohol and soaking for 6 hours at minus 15 degrees Celsius;

[0039] (3) Heat the product obtained in step (2) to 50° C., add mushroom alcohol, triisopropanolamine a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com