Method and device for removing oxygen-containing compounds in narrow fraction of Fischer-Tropsch synthetic oil

A Fischer-Tropsch synthetic oil and compound technology, which is applied in the fields of hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of high energy consumption and equipment costs, and complicated processes, so as to improve market competitiveness, simple process, The effect of high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

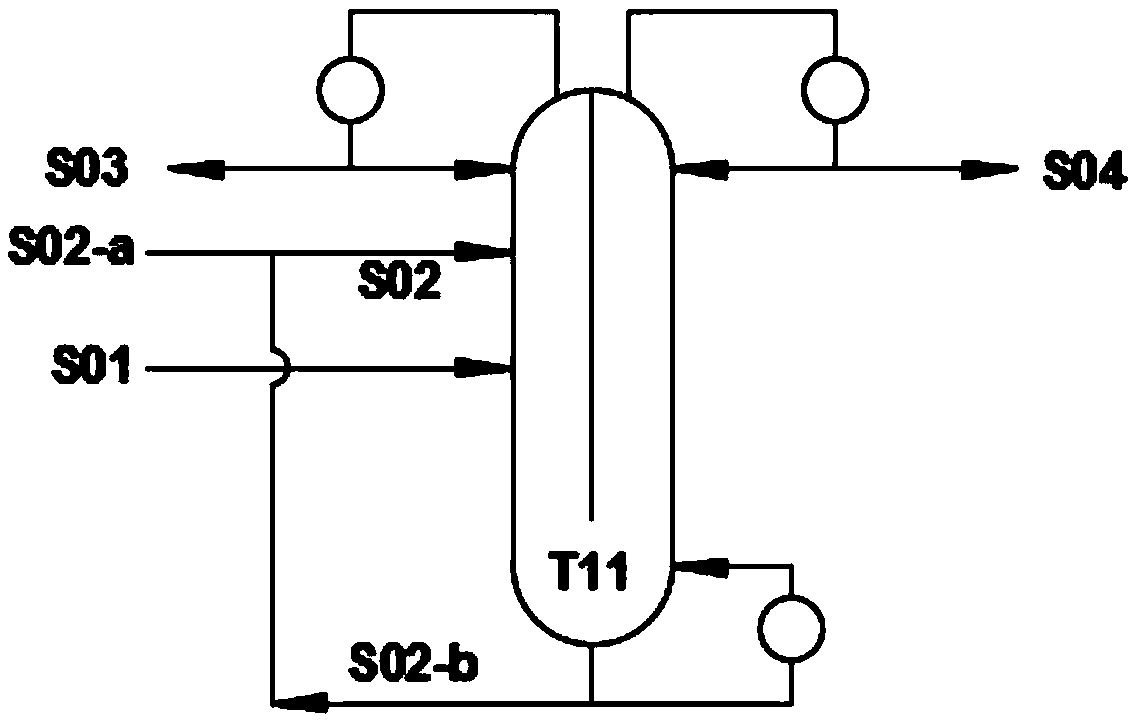

[0026] Applying the present invention to the process of removing oxygenates in Fischer-Tropsch synthetic light oil narrow cuts, such as figure 1As shown, it includes a dividing wall extractive distillation column (T11), a condenser, a reboiler, a pump, and related feed lines and lines connecting the above equipment. The raw material is 1000g C5 narrow fraction cut from Fischer-Tropsch synthetic oil light oil, including various C5 hydrocarbons and trace amounts of oxygen-containing compounds. The hydrocarbons mainly include normal alkanes and α-olefins, and also include some isoparaffins, internal olefins, branched olefins, and a small amount of cycloalkanes, aromatics, and cycloolefins. Oxygenated compounds include one or more of alcohols, aldehydes, ketones, acids, and esters. The extractant used is cyclohexanone. The number of theoretical plates on the feed side is 10, the number of theoretical plates on the non-feed side is 200, the number of theoretical plates from the b...

Embodiment 2

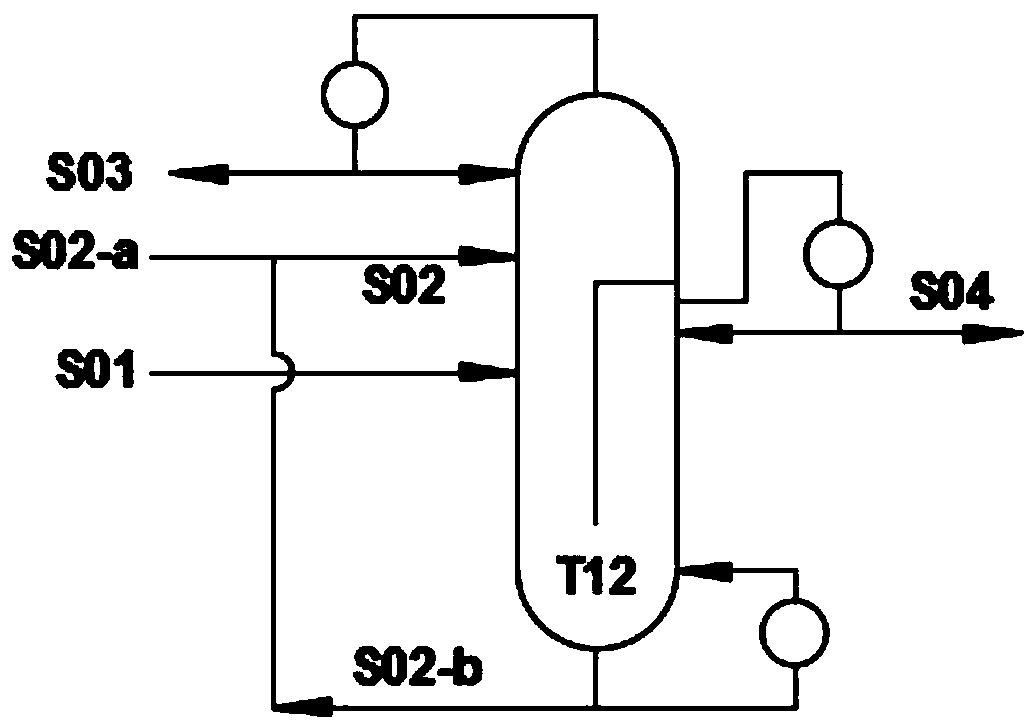

[0028] Applying the present invention to the process of removing oxygenates in Fischer-Tropsch synthetic light oil narrow cuts, such as figure 2 As shown, including the extractive rectification column with dividing wall (T12), condenser, reboiler, pump and related feed lines and lines connecting the above equipment. The raw material is 1000g C6 narrow fraction cut from Fischer-Tropsch synthetic oil light oil, including various C6 hydrocarbons and trace oxygen-containing compounds. The hydrocarbons mainly include normal alkanes and α-olefins, and also include some isoparaffins, internal olefins, branched olefins, and a small amount of cycloalkanes, aromatics, and cycloolefins. Oxygenated compounds include one or more of alcohols, aldehydes, ketones, acids, and esters. The extractant used is furfural. The number of theoretical plates on the feed side is 200, the number of theoretical plates on the non-feed side is 10, the number of theoretical plates from the top of the parti...

Embodiment 3

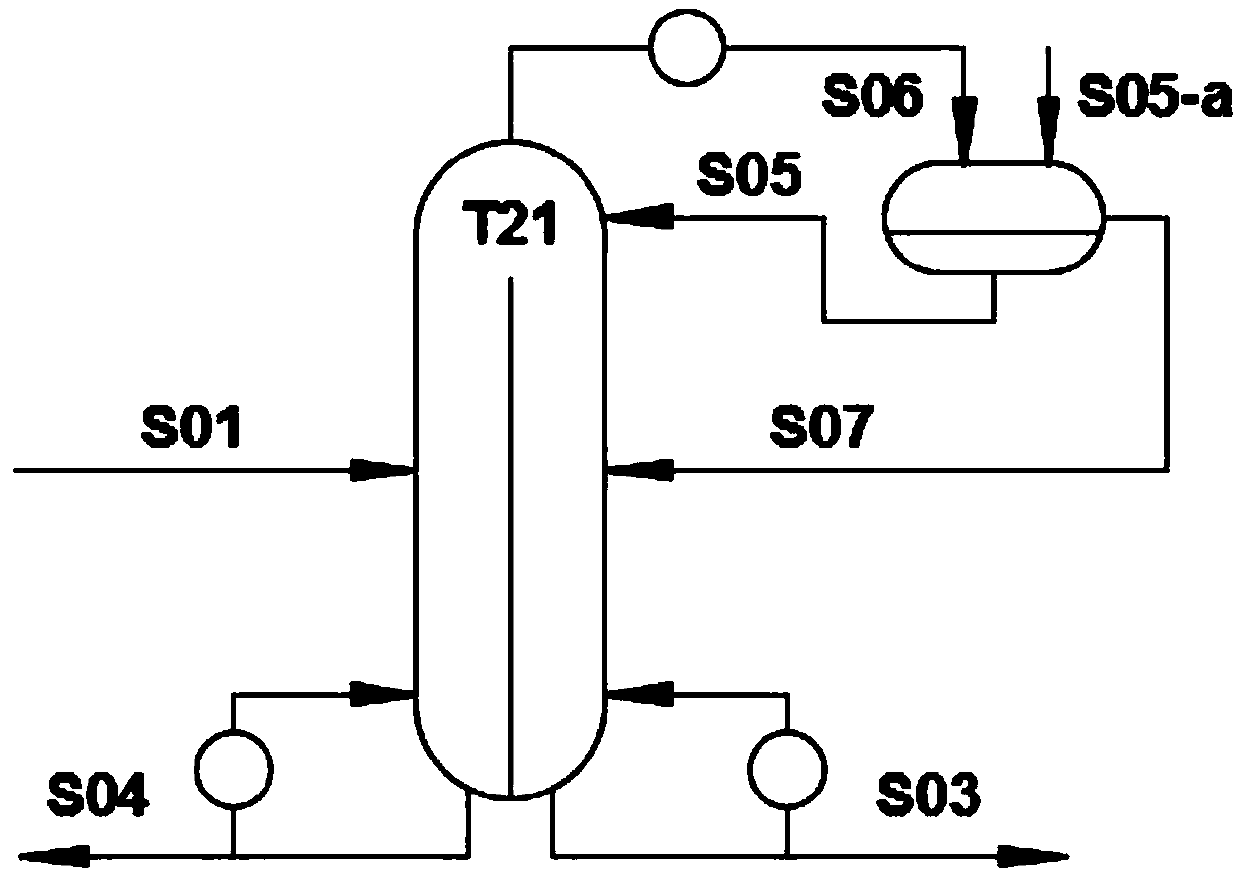

[0030] Applying the present invention to the process of removing oxygenates in Fischer-Tropsch synthetic light oil narrow cuts, such as image 3 As shown, it includes a dividing wall azeotropic distillation column (T21), a condenser, a reboiler, a pump, and related feed lines and lines connecting the above equipment. The raw material is 1000g C8 narrow fraction cut from Fischer-Tropsch synthetic oil light oil, including various C8 hydrocarbons and trace oxygen-containing compounds. The hydrocarbons mainly include normal alkanes and α-olefins, and also include some isoparaffins, internal olefins, branched olefins, and a small amount of cycloalkanes, aromatics, and cycloolefins. Oxygenated compounds include one or more of alcohols, aldehydes, ketones, acids, and esters. The entrainer used is formaldehyde-methanol aqueous solution. The number of theoretical plates on the feed side of the raw material is 50, the number of theoretical plates on the non-raw material feed side is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com