Refining method for polyformaldehyde dimethyl ether

A technology of dimethyl ether and purification method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of unfavorable expansion of production, affecting continuous and stable operation of the separation process of polyoxymethylene dimethyl ether, and processing time. long-term issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

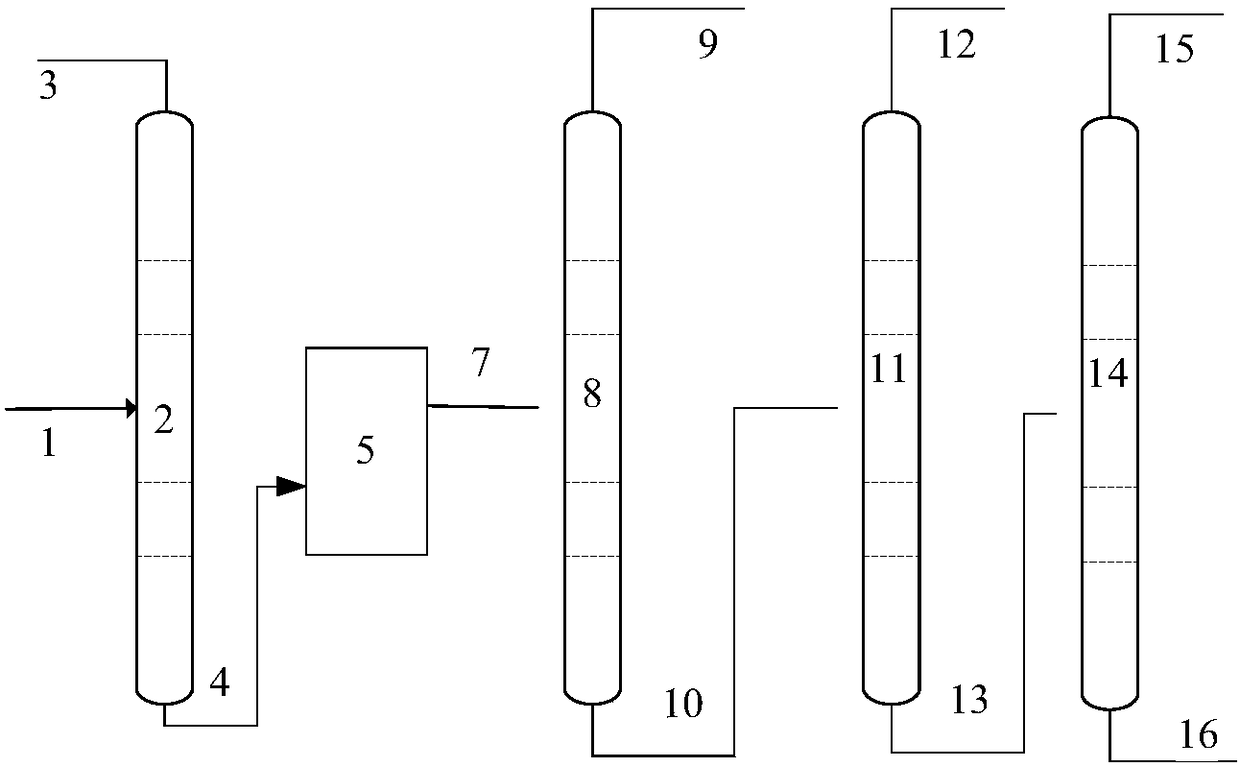

Method used

Image

Examples

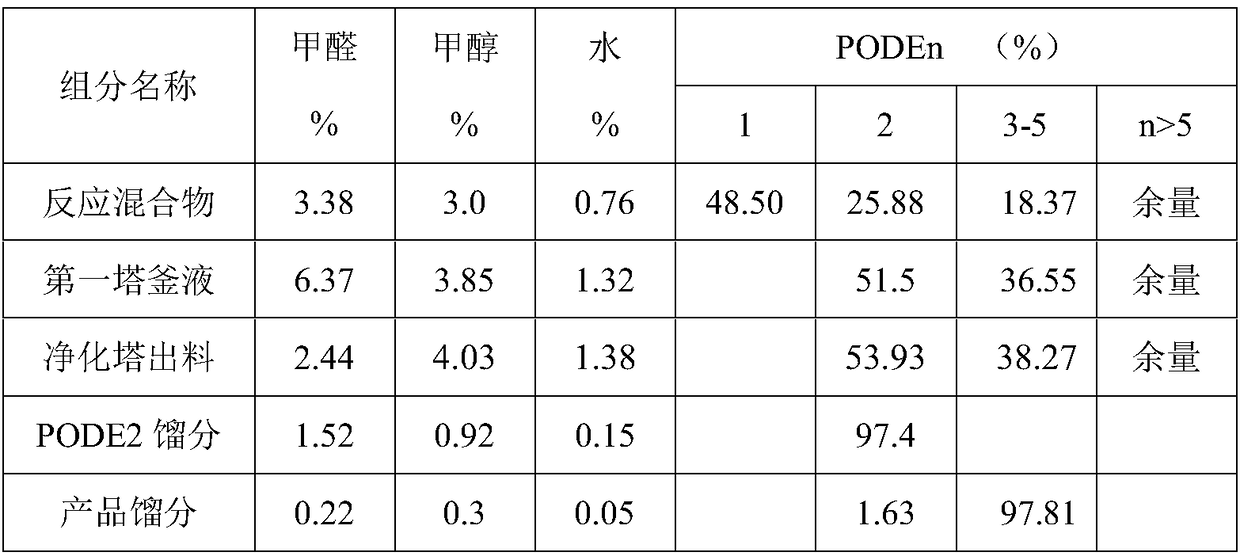

Embodiment 1

[0034] The reaction equilibrium mixture obtained by catalytic reaction with paraformaldehyde and methylal as raw materials is firstly subjected to atmospheric distillation in the first rectification tower to remove the first fraction to obtain the first tower still liquid with a temperature of 105°C. The kettle liquid of the first tower enters from the bottom through the insulation pipeline with Ca(OH) 2 It is a packing purification tower, the temperature of the purification tower is 100℃, the residence time is 10min, and the top of the tower contains methanol and PODE 2-5 The purification tower material. The discharge from the purification tower enters the dehydration tower, where the operating pressure is normal pressure, the reflux ratio is 8, and the tower bottom temperature is 110°C. The distillation is carried out, and fractions containing methanol and water are extracted from the top of the tower. The still liquid of the dehydration tower enters the second rectification t...

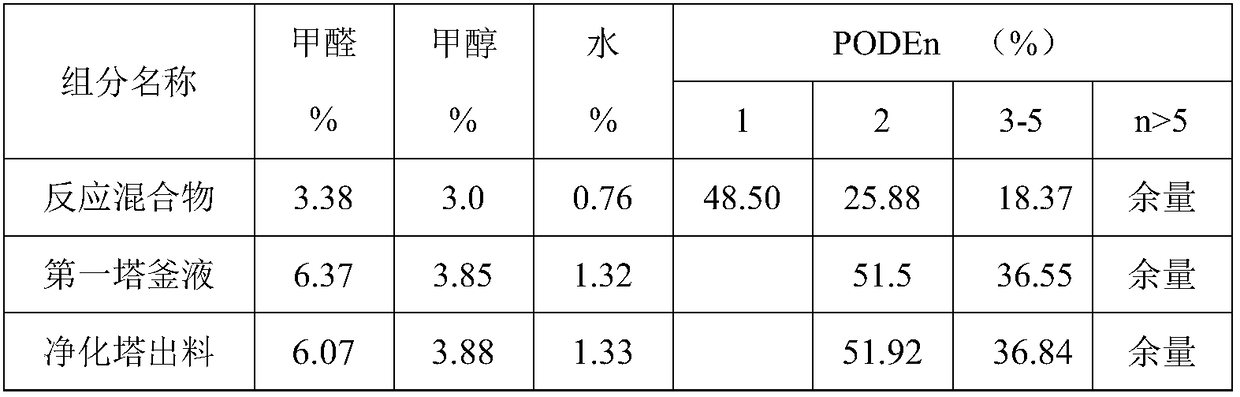

Embodiment 2

[0038] The reaction equilibrium mixture obtained by catalytic reaction with paraformaldehyde and methylal as raw materials is firstly subjected to atmospheric distillation in the first rectification tower to remove the first fraction to obtain the first tower still liquid with a temperature of 105°C. The kettle liquid of the first tower enters the purification tower with NaOH as the filler from the bottom through the insulated pipeline. The temperature of the purification tower is 100℃, the residence time is 10min, and the top of the tower contains methanol and PODE. 2-5 The purification tower material. The discharge from the purification tower enters the dehydration tower, where the operating pressure is normal pressure, the reflux ratio is 8, and the tower bottom temperature is 110°C. The distillation is carried out, and fractions containing methanol and water are extracted from the top of the tower. The still liquid of the dehydration tower enters the second rectification tow...

Embodiment 3

[0040] The reaction equilibrium mixture obtained by catalytic reaction with paraformaldehyde and methylal as raw materials is firstly subjected to atmospheric distillation in the first rectification tower to remove the first fraction to obtain the first tower still liquid with a temperature of 105°C. The kettle liquid in the first tower enters the Ca(OH) with a weight ratio of 1:1 from the bottom through the insulated pipeline 2 A purification tower with a mixture of NaOH and NaOH as packing. The temperature of the purification tower is 100℃, the residence time is 10min, and the top of the tower contains methanol and PODE. 2-5 The purification tower material. The discharge from the purification tower enters the dehydration tower, where the operating pressure is 0.2Mpa, the reflux ratio is 8, and the bottom temperature of the tower is 110°C. The distillation is carried out, and fractions containing methanol and water are extracted from the top of the tower. The still liquid of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com