Method for preparing urea from coal chemical industry

A technology for coal chemical industry and urea, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as limitation, inability to discharge impurities in coal chemical wastewater, inability to pre-filter coal chemical wastewater, etc., to improve filtration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

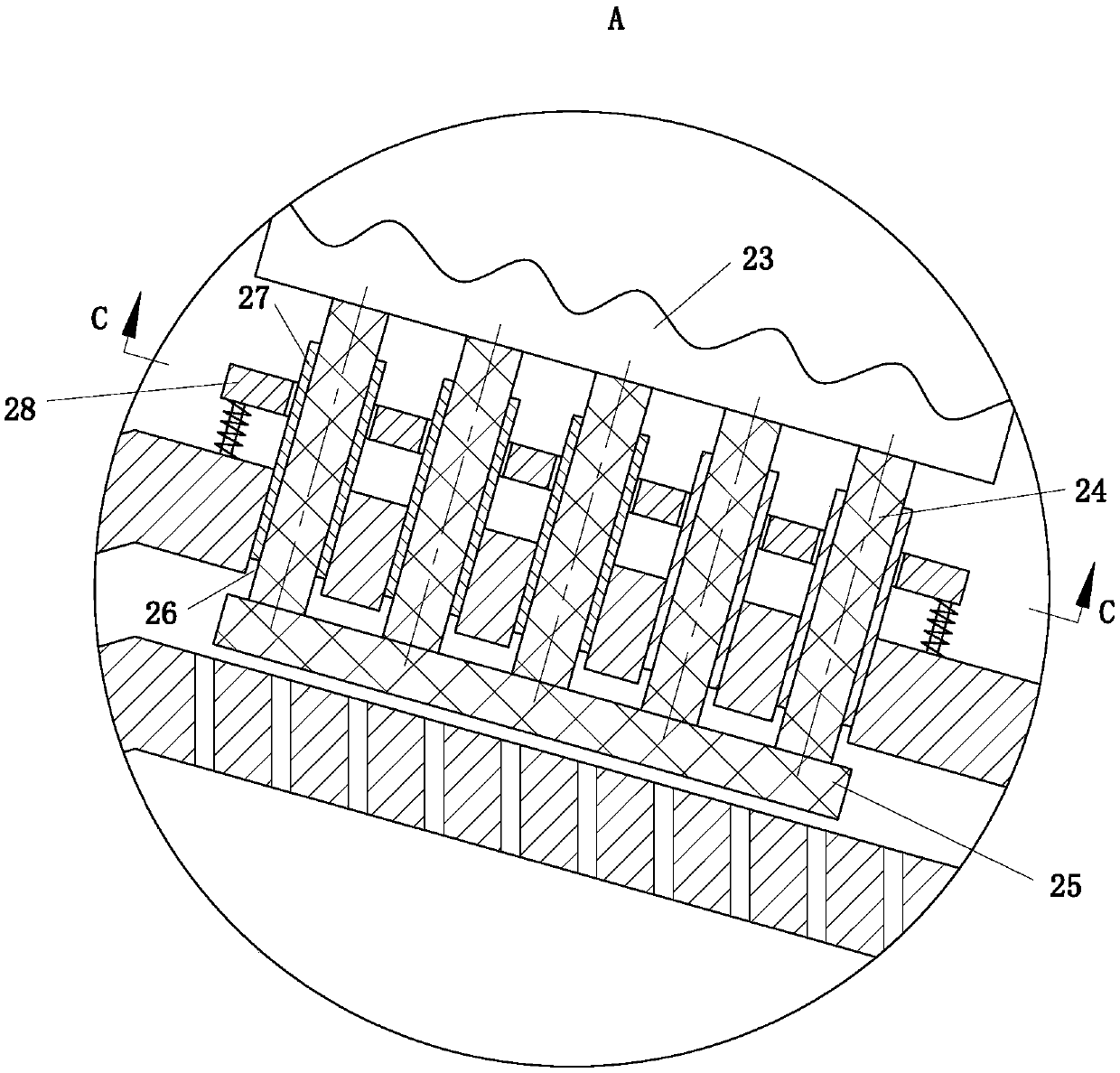

[0044] As an embodiment of the present invention, the osmosis unit 22 includes an absorption plate 23, a liquid guide column 24, and an output plate 25; the surface of the No. 1 fixed plate 2 is provided with a No. 1 opening 26 passing through the No. 1 fixed plate 2 , which is used to slide with the guide column 24; the absorbing plate 23 is located on the upper surface of the No. 1 fixed plate 2, and the absorbing plate 23 is installed on the output plate 25 through the guide column 24; the output plate 25 is located on the Between the fixed plate 2 and the No. 2 filter plate 21; Springs are fixedly installed between the output plate 25 and the bottom surface of the No. 1 fixed plate 2; Flexible absorbent material; the absorbing plate 23 absorbs the water, and the books on the absorbing plate 23 permeate to the output plate 25 through the liquid guiding column 24; 26 sliding, at the same time, between the output plate 25 and No. 2 filter plate 21, it is used to deform the ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap