Flame-retardant antibacterial masterbatch and preparation method thereof

A technology of antibacterial masterbatch and hyperbranched polymer, applied in the field of flame retardant masterbatch, can solve problems such as difficulty in processing and molding of blends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

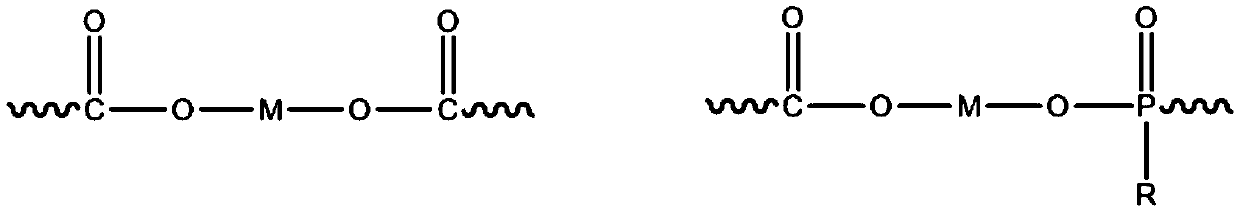

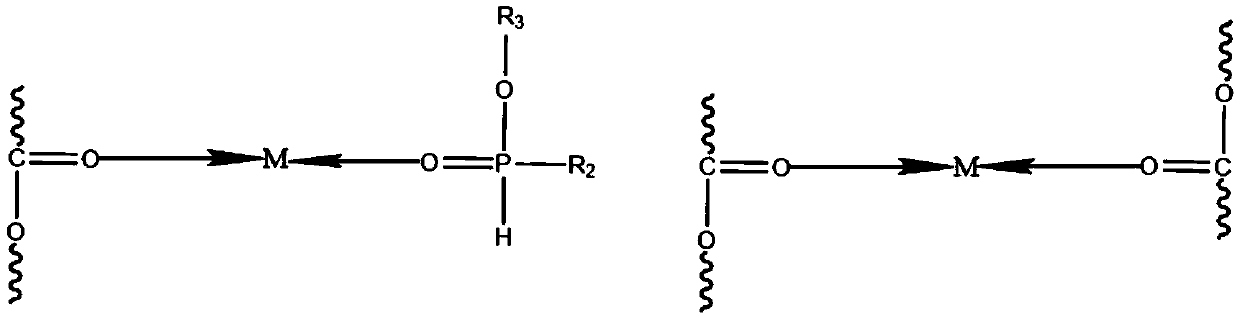

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of flame-retardant antibacterial masterbatch, concrete steps are as follows:

[0044] (1) prepare metal-modified hyperbranched polymer;

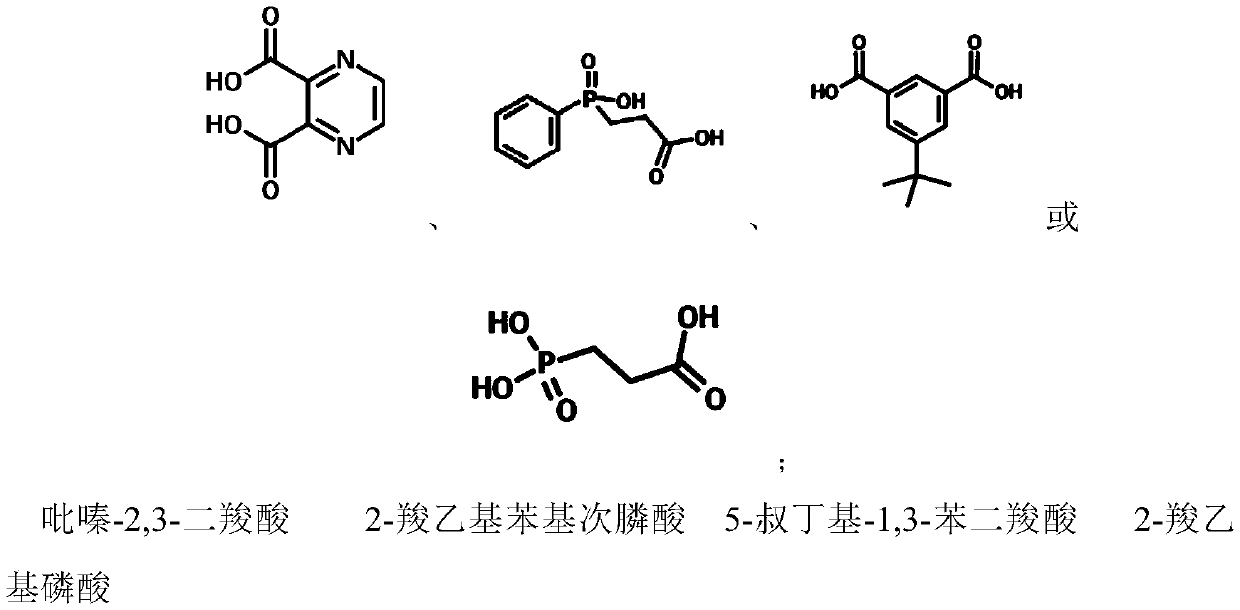

[0045] (1.1) Using A 2 +B 3 The synthetic method prepares the hyperbranched polymer that terminal group contains carboxyl group: Wherein A 2 Is pyrazine-2,3-dicarboxylic acid; B 3 is 1,1,1-tris(hydroxymethyl)propane;

[0046] The prepared hyperbranched polymer molecule containing carboxyl groups in the end groups contains ester groups, the number of carboxyl groups accounts for 25% of the total amount of end groups, the degree of branching is 60%, and the weight average molecular weight is 2000g / mol;

[0047] (1.2) Dissolving the hyperbranched polymer containing carboxyl group in the end group in chloroform to obtain a concentration of 0.7mol / L hyperbranched polymer solution containing carboxyl group in the end group, dissolving cobalt acetate in deionized water to obtain a concentration of 0.8mol / L The met...

Embodiment 2

[0055] The preparation method of flame-retardant antibacterial masterbatch, concrete steps are as follows:

[0056] (1) prepare metal-modified hyperbranched polymer;

[0057] (1.1) Using A 2 +B 3 The synthetic method prepares the hyperbranched polymer that terminal group contains carboxyl group: Wherein A 2 For: 2-carboxyethylphenylphosphinic acid; B 3 For: three (2-carboxyethyl) isocyanurate;

[0058] The prepared hyperbranched polymer molecule containing carboxyl groups in the end groups contains ester groups, the number of carboxyl groups accounts for 27% of the total amount of end groups, the degree of branching is 53%, and the weight average molecular weight is 43000g / mol;

[0059] (1.2) Dissolving the hyperbranched polymer containing carboxyl group in the end group in acetone to obtain a concentration of 0.85mol / L hyperbranched polymer solution containing carboxyl group in the end group, dissolving nickel acetate in deionized water to obtain a concentration of 0.95mo...

Embodiment 3

[0067] The preparation method of flame-retardant antibacterial masterbatch, concrete steps are as follows:

[0068] (1) prepare metal-modified hyperbranched polymer;

[0069] (1.1) Using A 2 +B 3 The synthetic method prepares the hyperbranched polymer that terminal group contains carboxyl group: Wherein A 2 Is: 5-tert-butyl-1,3-benzenedicarboxylic acid; B 3 For: 2,4,5-trihydroxybutyrophenone;

[0070] The prepared hyperbranched polymer molecule containing carboxyl groups in the end groups contains ester groups, the number of carboxyl groups accounts for 25% of the total amount of end groups, the degree of branching is 30%, and the weight average molecular weight is 15000g / mol;

[0071] (1.2) the hyperbranched polymer solution containing carboxyl group in the end group is dissolved in N,N-dimethylformamide to obtain a concentration of hyperbranched polymer solution containing carboxyl group in the end group of 0.9mol / L, copper acetate is dissolved in A metal ion solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com