An environmentally friendly interior wall coating prepared from waste powder of optical fiber preform rods

A technology for optical fiber prefabricated rods and interior wall coatings, applied in the direction of coatings, etc., can solve the problems that interior wall coatings cannot have both functionality and environmental protection, and achieve increased photocatalytic degradation activity, strong ion exchange performance, and increased wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

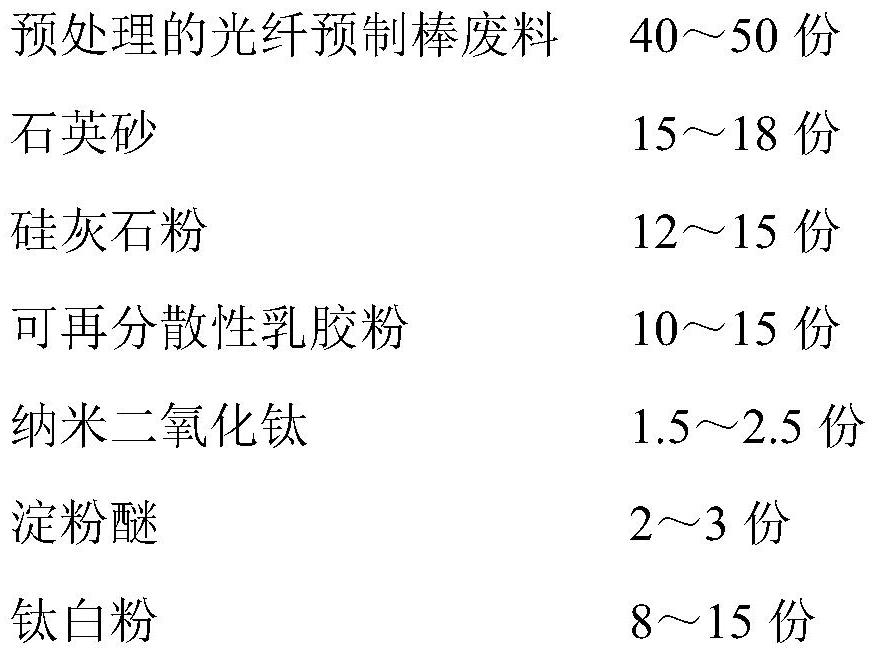

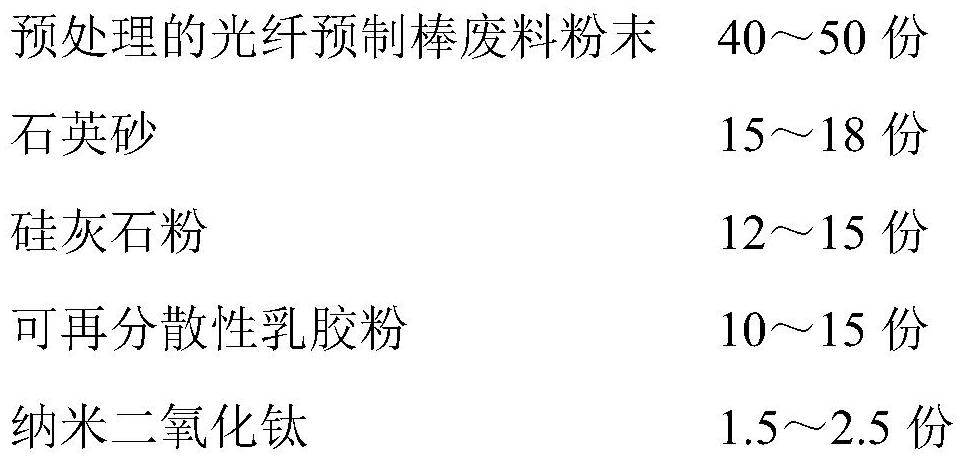

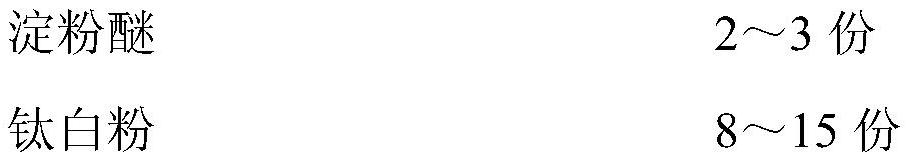

[0028] (1) Grinding each component: 44 parts by weight of waste powder of optical fiber preform, 17 parts by weight of quartz sand, 13 parts by weight of wollastonite powder, 13 parts by weight of dispersible latex powder, 3 parts by weight of starch ether, Put 8 parts by weight of titanium dioxide into a powder grinder for mixing and grinding, and pass through a 300-mesh sieve after grinding to obtain a mixed powder.

[0029] (2) Preparation of mixed powder: Add 2 parts by weight of weighed nano-titanium dioxide into the mixed powder, then put it into a mixer and stir evenly to obtain an environment-friendly interior wall paint.

[0030] Add the prepared environment-friendly interior wall paint into 200 parts by weight of clear water, stir it and put it into the spray gun. It was observed that the coating had good sag resistance. After thorough drying, the surface has good flatness, fineness and smoothness, and there is no obvious scratch after being lightly polished with wa...

Embodiment 2

[0035] (1) Weighing and grinding each component: 49 parts by weight of the weighed optical fiber preform waste powder, 13 parts by weight of quartz sand, 12 parts by weight of wollastonite powder, 15 parts by weight of dispersible latex powder, 3 parts by weight of starch ether Parts by weight and 8 parts by weight of titanium dioxide are put into a powder grinder for mixing and grinding, and after grinding, pass through a 300-mesh sieve to obtain mixed powder.

[0036] (2) Preparation of mixed powder: Add 2 parts by weight of weighed nano-titanium dioxide into the mixed powder, then put it into a mixer and stir evenly to obtain an environment-friendly interior wall paint.

[0037] Add the prepared environmentally friendly interior wall paint into 200 parts by weight of clear water, stir it and put it into the spray gun. It was observed that the coating had good sag resistance. After thorough drying, the surface has good flatness, fineness and smoothness, and there is no obvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com