Connecting tape special for high-speed SMT chip mounter and preparation method thereof

A placement machine, high-speed technology, applied in the direction of adhesives, pressure-sensitive films/sheets, film/sheet-like adhesives, etc., can solve the problem of inability to maintain surface printing or coding capabilities for a long time, and achieve good machine application The effect of durability, printing or inkjet coding, and excellent optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

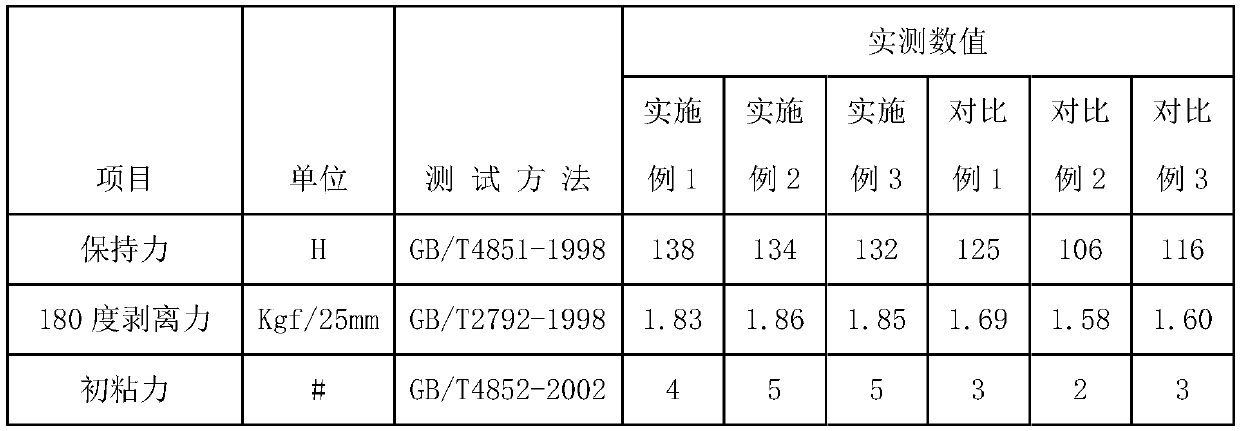

Embodiment 1

[0028] A splicing tape specially used for high-speed SMT placement machines, characterized in that: the base material is 25, 36 micron PET, the tensile strength of the PET is DM>150Pa, CD>120Pa, and the PET coating surface Carry out surface corona treatment so that its surface energy is 56-60DN; the PET coating surface is coated with glue, and the glue includes acrylic pressure-sensitive adhesive, isocyanate, melamine hardener and solvent; the molecular weight of the acrylic pressure-sensitive adhesive 650,000, with a solid content of 40% to 45%; acrylic pressure-sensitive adhesive, isocyanate and melamine hardener are added in a mass ratio of 100:2.7:0.7 and stirred evenly by a stirring device; after drying, the glue is bonded with silicone oil Release PET backing paper. The solvent is ethyl acetate. The glue also contains an epoxy-modified hydroxyacrylic resin, and the epoxy equivalent of the epoxy-modified hydroxyacrylic resin is 500. The addition amount of the epoxy-modi...

Embodiment 2

[0038] A splicing tape specially used for high-speed SMT placement machines, characterized in that: the base material is 25, 36 micron PET, the tensile strength of the PET is DM>150Pa, CD>120Pa, and the PET coating surface Carry out surface corona treatment so that its surface energy is 56-60DN; the PET coating surface is coated with glue, and the glue includes acrylic pressure-sensitive adhesive, isocyanate, melamine hardener and solvent; the molecular weight of the acrylic pressure-sensitive adhesive 800,000, with a solid content of 40% to 45%; acrylic pressure-sensitive adhesive, isocyanate and melamine hardener are added in a mass ratio of 100:2.5:0.8 and stirred evenly by a stirring device; the glue is bonded with silicone oil after drying Release PET backing paper. The solvent is ethyl acetate. The glue also contains an epoxy-modified hydroxyacrylic resin, and the epoxy equivalent of the epoxy-modified hydroxyacrylic resin is 600. The addition amount of the epoxy-modif...

Embodiment 3

[0048]A splicing tape specially used for high-speed SMT placement machines, characterized in that: the base material is 25, 36 micron PET, the tensile strength of the PET is DM>150Pa, CD>120Pa, and the PET coating surface Carry out surface corona treatment so that its surface energy is 56-60DN; the PET coating surface is coated with glue, and the glue includes acrylic pressure-sensitive adhesive, isocyanate, melamine hardener and solvent; the molecular weight of the acrylic pressure-sensitive adhesive 500,000, with a solid content of 40% to 45%; acrylic pressure-sensitive adhesive, isocyanate and melamine hardener are added in a mass ratio of 100:3.0:0.5 and stirred evenly by a stirring device; the glue is bonded with silicone oil after drying Release PET backing paper. The solvent is ethyl acetate. The glue also contains epoxy-modified hydroxyacrylic resin, and the epoxy equivalent of the epoxy-modified hydroxyacrylic resin is 400. The addition amount of the epoxy-modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com