Standardized high-throughput three-dimensional cell preparation device and application thereof

A technology of three-dimensional cells and preparation devices, which is applied in the direction of tissue cell/virus culture devices, measurement devices, biochemical equipment and methods, etc., which can solve the problem of combining patterned microwells with commercial well plates and limiting the promotion and use of microwell methods , unable to carry out standardized operations and other problems, to achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

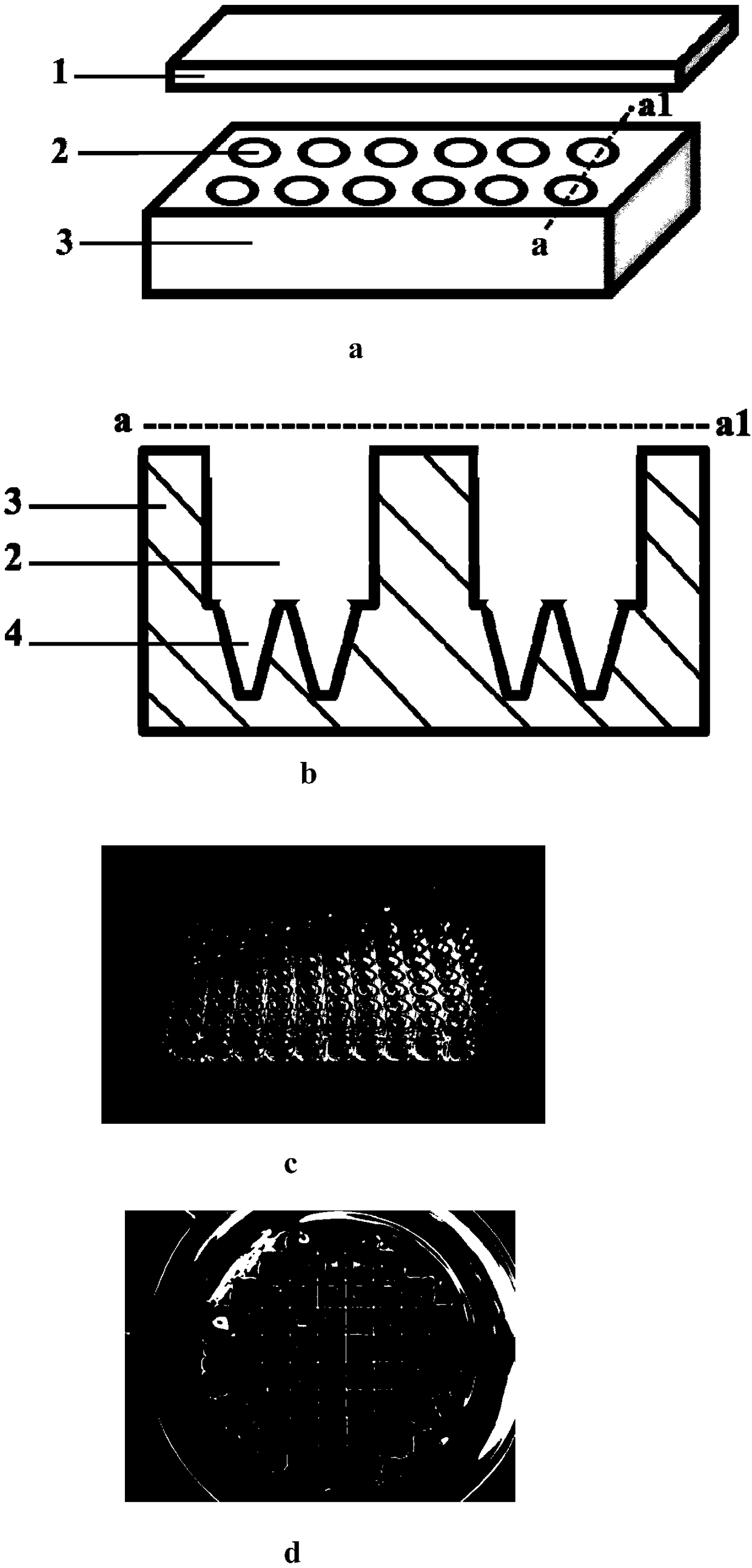

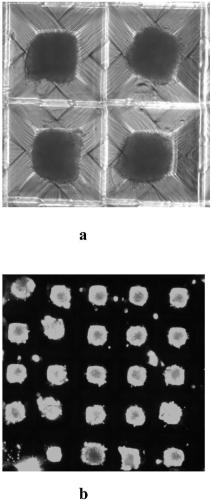

[0035] Such as figure 1 The standardized high-throughput three-dimensional cell preparation device shown in a, in a commercial 96-well plate, has an array of concave structures at the bottom. One of the fabrication methods is as follows. Firstly, a PDMS chip with an array of recessed structures is fabricated into a circular chip with a diameter of 6 mm. The concave structure on the chip is an inverted trapezoidal structure, the diameter of the upper part is 600 μm, and the diameter of the lower part is 300 μm. The chip was fixed at the bottom of a commercial 96-well plate, and the effect was as follows: figure 1 as shown in b.

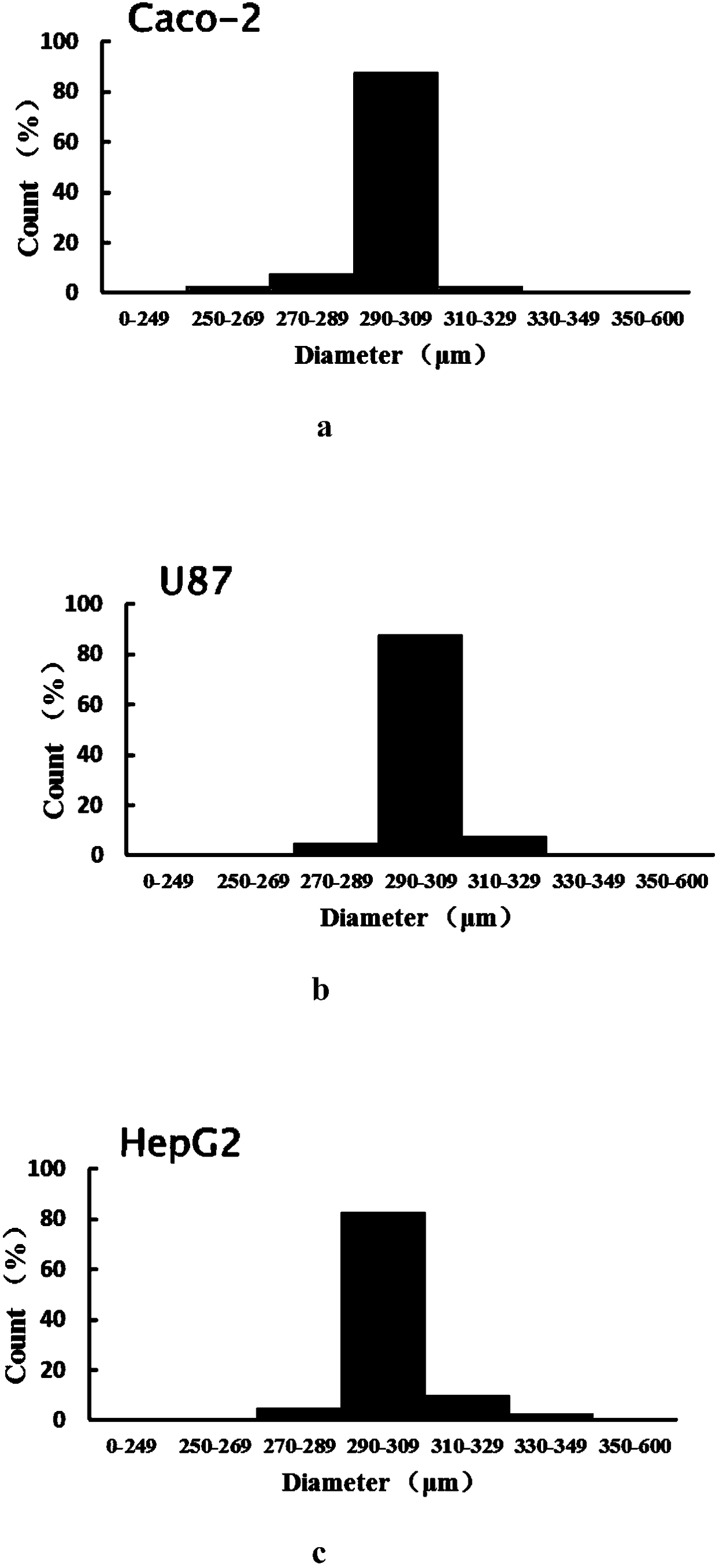

[0036] The bottom of the well plate was treated with 0.2% PF-127 for 4 hours and rinsed three times with PBS. Caco-2, U87, HepG2 cells were digested and resuspended in cell culture medium at 3×10 5 The density of cells / well was inoculated into each well respectively, and cultured in a cell culture incubator. After 24 hours, three-dimensional cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com