Graphene-based metal composite antistatic thin film and preparation method

A graphene and metal-based technology, which is applied in the field of graphene-based metal composite antistatic film and preparation, can solve the problems of poor antistatic performance and uneven dispersion of conductive fillers, and achieve firm bonding, not easy to fall off, and continuous preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

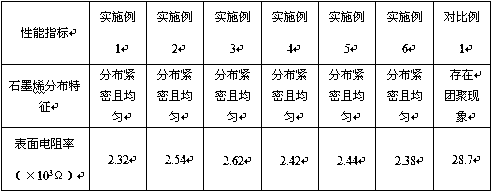

Examples

Embodiment 1

[0034] The preparation process is:

[0035] (1) The polymer matrix is heated to melt, then extruded to make a polymer film matrix, and drawn into the vacuum evaporation equipment; the matrix polymer is polyethylene; the vacuum degree of the vacuum evaporation equipment is 0.0006Pa, The pulling surface speed is 3m 2 / min;

[0036] (2) Put a copper source in the evaporation chamber under the film;

[0037] (3) The honeycomb three-dimensional graphene is introduced into the vacuum evaporation equipment at a high speed, and then the copper source is heated and sublimated, and the copper gaseous particles are transported to the surface of the polymer film substrate from the bottom to the top; The feeding speed is 3g / s; the heating temperature of the copper source is 2590℃;

[0038] (4) Using liquid nitrogen quench deposition, metal copper is quenched to fix the honeycomb three-dimensional graphene on the surface of the base film, the three-dimensional graphene overlaps each ot...

Embodiment 2

[0044] The preparation process is:

[0045] (1) The polymer matrix is heated to melt, then extruded to make a polymer film matrix, and pulled into the vacuum evaporation equipment; the matrix polymer is polyethylene; the vacuum degree of the vacuum evaporation equipment is 0.0003Pa, The pulling surface speed is 2m 2 / min;

[0046] (2) Put a copper source in the evaporation chamber under the film;

[0047] (3) The honeycomb three-dimensional graphene is introduced into the vacuum evaporation equipment at a high speed, and then the copper source is heated and sublimated, and the copper gaseous particles are transported to the surface of the polymer film substrate from the bottom to the top; The feeding speed is 3g / s; the heating temperature of the copper source is 2590℃;

[0048] (4) Using liquid nitrogen quench deposition, metal copper is quenched to fix the honeycomb three-dimensional graphene on the surface of the base film, the three-dimensional graphene overlaps each o...

Embodiment 3

[0054] The preparation process is:

[0055] (1) The polymer matrix is heated to melt, then extruded to make a polymer film matrix, and pulled into the vacuum evaporation equipment; the matrix polymer is polyethylene; the vacuum degree of the vacuum evaporation equipment is 0.0001Pa, The pulling surface speed is 2m 2 / min;

[0056] (2) Put a copper source in the evaporation chamber under the film;

[0057] (3) The honeycomb three-dimensional graphene is introduced into the vacuum evaporation equipment at a high speed, and then the copper source is heated and sublimated, and the copper gaseous particles are transported to the surface of the polymer film substrate from the bottom to the top; The feeding speed is 2g / s; the heating temperature of the copper source is 2580℃;

[0058] (4) Using liquid nitrogen quench deposition, metal copper is quenched to fix the honeycomb three-dimensional graphene on the surface of the base film, the three-dimensional graphene overlaps each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com