A kind of carbon nanotube/activated carbon mesoporous composite pellet and preparation method thereof

A technology of carbon nanotubes and activated carbon, which is applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of poor spheroidization and size uniformity, and achieve good sphericity, uniform size, and elastic modulus. A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

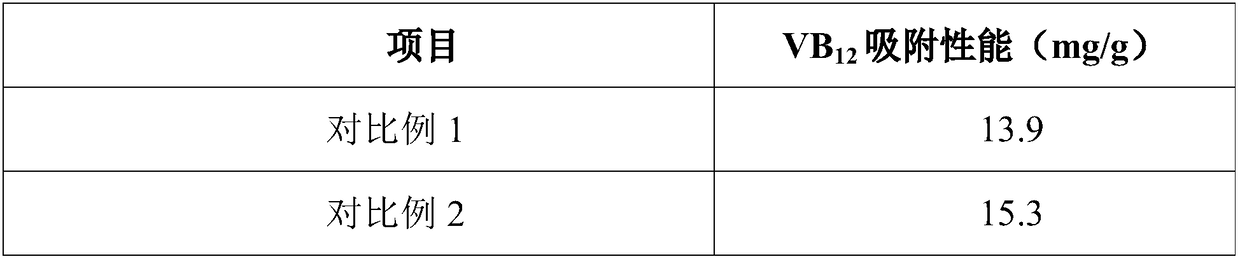

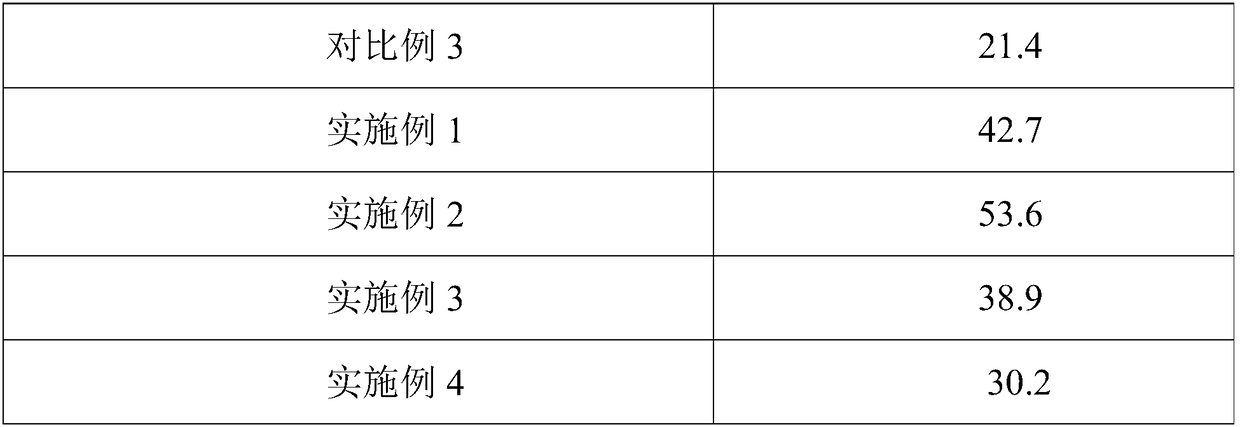

Examples

Embodiment 1

[0045] This embodiment provides a carbon nanotube / activated carbon mesoporous composite pellet and a preparation method thereof, the preparation method comprising the following steps:

[0046] S1. Acidification and dispersion treatment of carbon nanotubes: First, weigh 10 g of carbon nanotubes and put them into a planetary ball mill, mill them for 40 minutes at a rate of 200 rpm, and put the milled carbon nanotubes into hydrofluoric acid with a mass concentration of 1%. Soak for 24 hours; then wash the carbon nanotubes twice with deionized water, then add them to a mixed acid of concentrated sulfuric acid and concentrated nitric acid (volume ratio: 3:1) and reflux at 140° C. for 1 hour. The treated carbon nanotubes are washed with deionized water until the pH value of the washing solution is 5, and then freeze-dried before use;

[0047] S2, weigh 30g carbon nanotubes, starch 60g, powdered phenolic resin 20g, microcrystalline cellulose 10g after processing in step S1, add deion...

Embodiment 2

[0052] This embodiment provides a carbon nanotube / activated carbon mesoporous composite pellet and a preparation method thereof, the preparation method comprising the following steps:

[0053] S1. Acidification and dispersion treatment of carbon nanotubes: First, weigh 10 g of carbon nanotubes and put them into a planetary ball mill, mill them for 30 minutes at a rate of 600 rpm, and soak the milled carbon nanotubes in a nitric acid solution with a mass concentration of 30%. 4h; the above-mentioned carbon nanotubes were washed twice with deionized water, then added to a mixed acid of concentrated sulfuric acid and concentrated nitric acid (volume ratio: 2:1) and refluxed at 125°C for 4h. The treated carbon nanotubes are washed with deionized water until the pH value of the washing solution is 7, and then freeze-dried for use;

[0054] S2, weigh 40g carbon nanotubes, starch 55g, powdered phenolic resin 30g, microcrystalline cellulose 15g after processing in step S1, add deioniz...

Embodiment 3

[0059] This embodiment provides a carbon nanotube / activated carbon mesoporous composite pellet and a preparation method thereof, the preparation method comprising the following steps:

[0060] S1. Acidification and dispersion treatment of carbon nanotubes: First, weigh 10 g of carbon nanotubes and put them into a planetary ball mill, mill them at a rate of 1000 rpm for 20 minutes, and put the milled carbon nanotubes into hydrofluoric acid with a mass concentration of 2%. Soak for 24 hours; then wash the carbon nanotubes twice with deionized water, then add them into a mixed acid of concentrated sulfuric acid and concentrated nitric acid (volume ratio: 1:1) and reflux at 110° C. for 6 hours. The treated carbon nanotubes are washed with deionized water until the pH value is 6, and then freeze-dried before use;

[0061] S2. Weigh 50g of carbon nanotubes, 60g of powdered phenolic resin, and 50g of microcrystalline cellulose after processing in step S1, add 100g of deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com