Environment-friendly electroplating device for jewelry processing

An electroplating device and an environment-friendly technology, which is applied in the field of an environment-friendly electroplating device for jewelry processing, can solve the problems of the surrounding environment and human health adverse effects, random emissions, etc., and achieve improved electroplating effects, reasonable and orderly distribution, and convenient jewelry electroplating. Effect

Inactive Publication Date: 2018-12-28

史晓宗

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The wastewater produced by the existing jewelry electroplating equipment after electroplating treatment is often discharged randomly after preliminary treatment, which has a serious adverse effect on the surrounding environment and human health.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

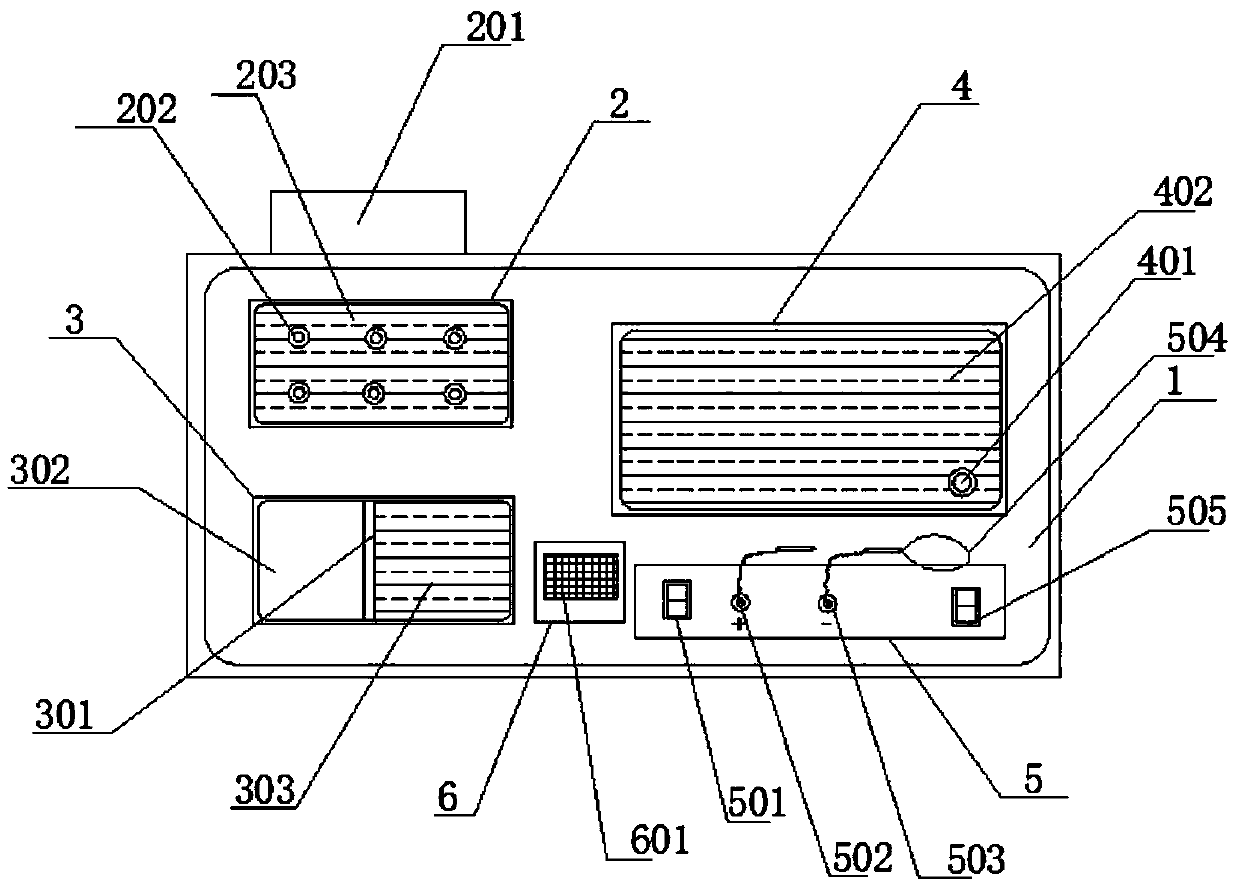

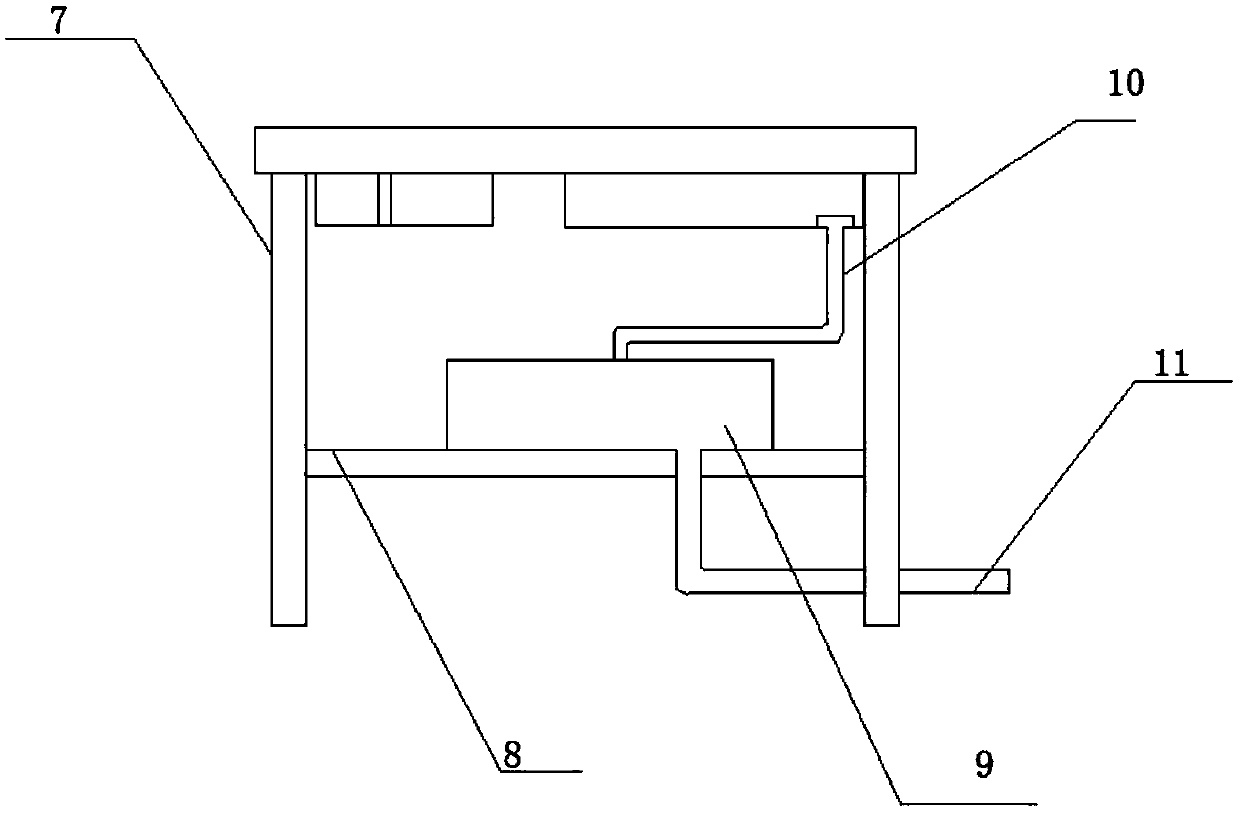

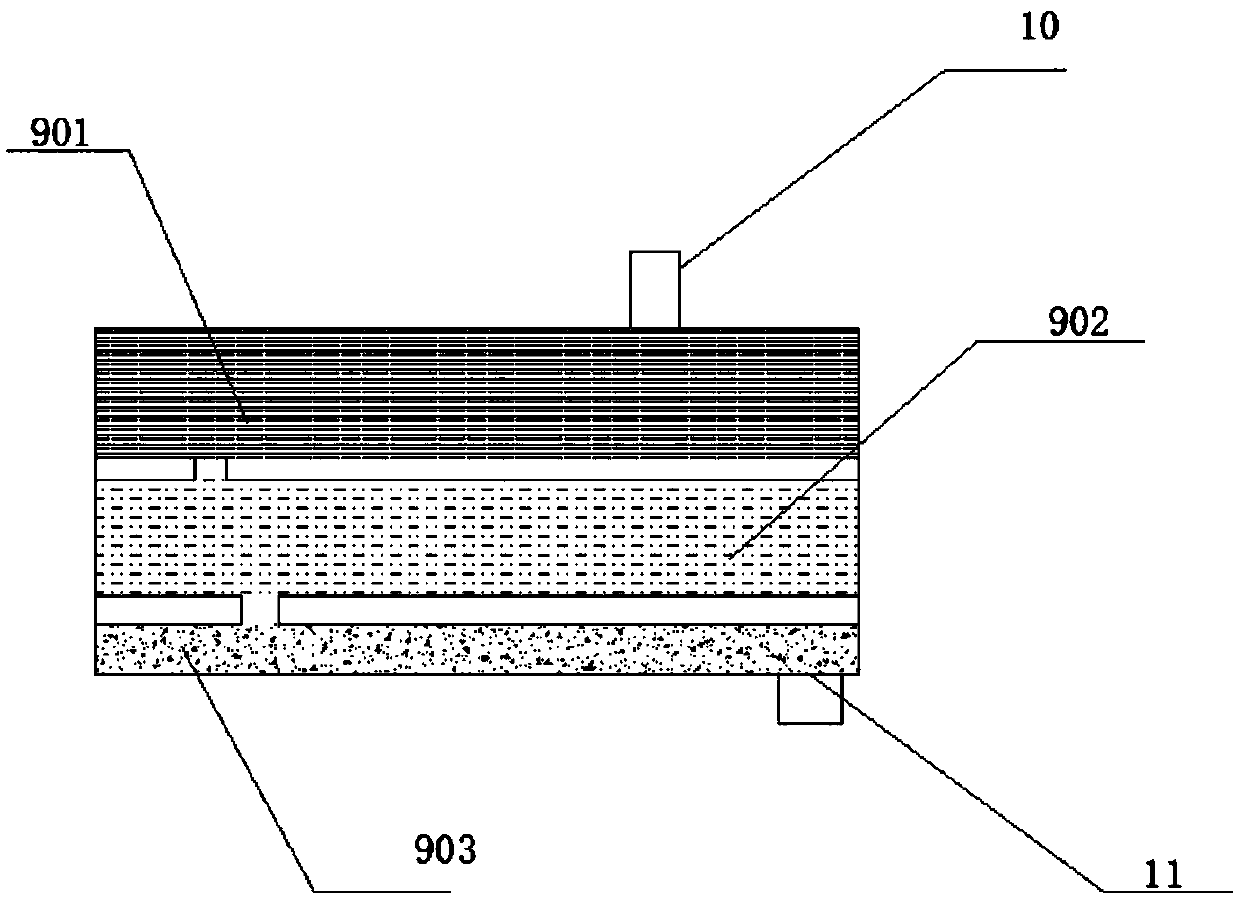

The invention discloses an environment-friendly electroplating device for jewelry processing. The environment-friendly electroplating device for jewelry processing comprises a workbench, wherein the workbench comprises an ultrasonic cleaning tank mechanism, a water cleaning tank, an electroplating tank, a control panel and a waste liquid treatment tank, wherein the ultrasonic cleaning tank and thewater cleaning tank are mounted on one side of the surface of the workbench in parallel; the electroplating tank is mounted on the other side of the surface of the workbench; the control panel is arranged on one side of the electroplating tank; the waste liquid treatment tank is mounted below the electroplating tank on the workbench. Through the arrangement of the water cleaning tank, the electroplating tank and the waste liquid treatment tank, the environment-friendly electroplating device for jewelry processing not only guarantees a better jewelry electroplating effect, but also performs multiply treatments on a waste liquid produced after electroplating to finally reach a dischargeable standard, so that the pressure of a jewelry electroplating technology on the environment is greatly reduced.

Description

technical field The invention belongs to the technical field of electroplating equipment, and in particular relates to an environment-friendly electroplating device for jewelry processing. Background technique Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It is a process of using electrolysis to attach a layer of metal film to the surface of metal or other material parts to prevent metal oxidation ( Such as rust), improve wear resistance, conductivity, reflectivity and corrosion resistance (copper sulfate, etc.) and enhance the appearance. Electroplating is a very widely used surface optimization treatment technology in the jewelry production process. It is a process that uses electrochemical methods to precipitate metal and alloy coatings on the surface of jewelry. Under the action of the electrode reaction, it is reduced to a metal atom, and the metal is deposited on t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D17/00C25D7/00B08B3/12

CPCB08B3/12C25D7/005C25D17/00C25D21/16

Inventor 史晓宗

Owner 史晓宗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com