Underwear dyeing process

A technology for crafts and underwear, applied in the field of textile dyeing and finishing, can solve problems such as easy breeding of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

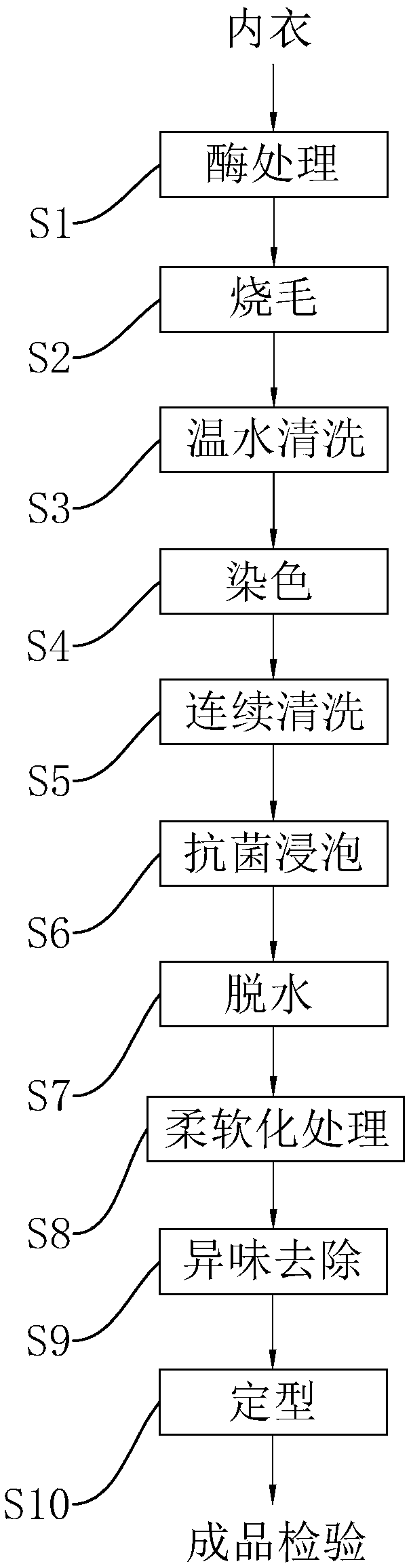

[0043] refer to figure 1 , an underwear dyeing process, the seamless underwear made of cotton is used to carry out the following steps:

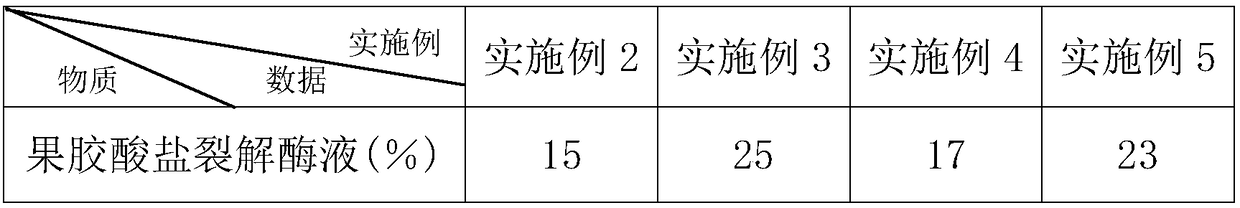

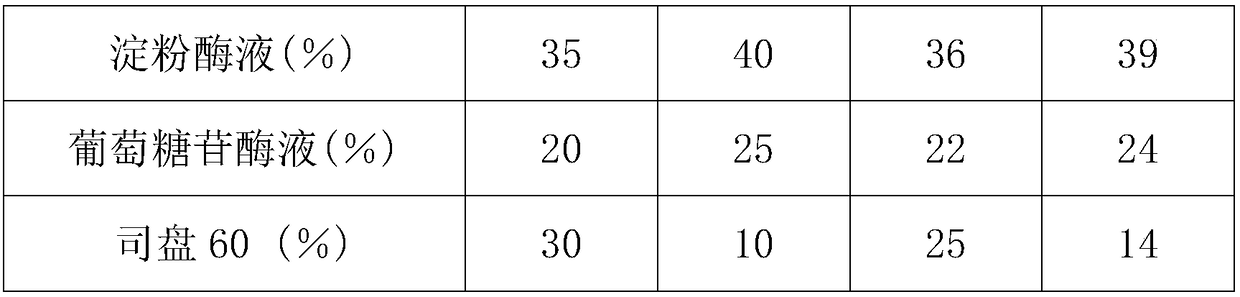

[0044] S1: The seamless underwear is subjected to enzyme treatment. Put the finished seamless underwear into a container containing various enzymes, soak it for 3 hours, and then dissolve and remove some impurities it originally contained. The enzymes contained in the container and their mass percentages are: 20% pectate lyzing enzyme solution, 37% amylase solution, 23% glucosidase solution and 20% Span 60, and the reaction temperature is 52.5°C , the pH is controlled at 5.3.

[0045] S2: Transport the above-mentioned enzyme-treated seamless underwear to the singeing machine for singeing, and burn off the fluff on the surface of the seamless underwear to make the surface of the seamless underwear smooth and clean. Dyeing defects will occur due to the presence of fluff when placed for dyeing .

[0046] S3: washing the above-mentioned seam...

Embodiment 34

[0074] The difference between Example 34 and Example 1 is that, S5: Continuously wash the dyed seamless underwear. Wash the dyed seamless underwear with warm water at 30°C for 40 minutes, then wash the seamless underwear with 80°C water for 20 minutes, then rinse with hot water and cold water alternately. 40 minutes; the method of alternate washing is to first wash with 65°C water for 5 minutes, and then use 20°C water for 5 minutes.

Embodiment 35

[0075] The difference between Example 35 and Example 1 is that, S5: Continuously wash the dyed seamless underwear. First wash the dyed seamless underwear with warm water at 40°C for 60 minutes, then wash the seamless underwear with water at 95°C for 30 minutes, then rinse with hot water and cold water alternately, rinse 60 minutes; the method of alternate washing is to first wash with 75°C water for 10 minutes, and then use 35°C water for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com