Downhole string creeping testing method and device

A downhole pipe string and testing method technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of complex structure and errors, and achieve the effect of simple structure, reliable operation and accurate creep displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings, without limiting the protection scope of the present invention. The following descriptions are only preferred embodiments of the present invention, and other equivalent changes using the present invention shall fall within the protection scope of the present invention.

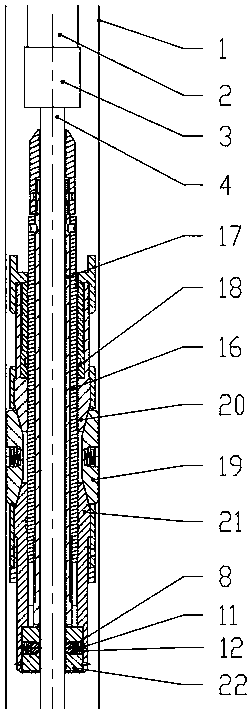

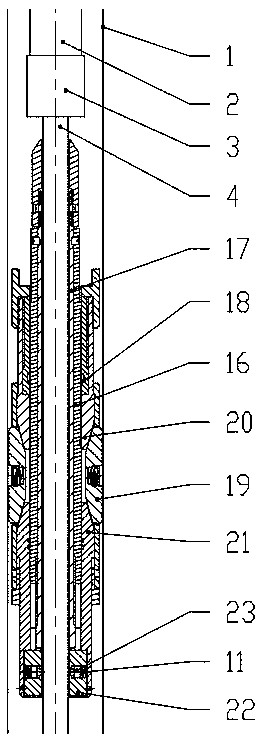

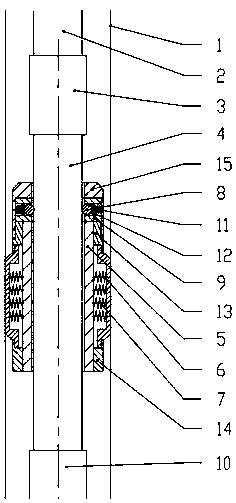

[0015] The creep test method of the downhole tubing string is as follows: a section of oil pipe is connected to the lower end of the downhole production tubing string 2 through the upper coupling 3 as the test tube 4, and the test friction parts that can produce friction scratches with the test tube 4 are installed In the creep test device, the creep test device is fixed between the casing 1 and the test tube 4, so that the test friction parts installed in the creep test device are tightly against the outer wall of the test tube 4; when the production string 2 creeps And when the test tube 4 is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com