Plate-type heat transfer engine

A technology of plate heat exchange and plate heat exchanger, which is applied in the direction of engine components, combustion engines, hot gas variable displacement engine devices, etc., can solve the problems of short fluid channels and inability to apply high-temperature and high-pressure steam heat recycling, and achieve the production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

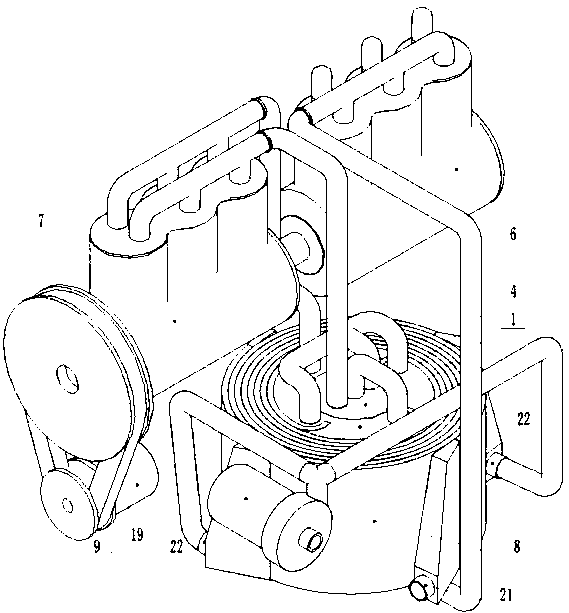

[0041] A plate heat exchange engine includes a heating device 4 , an electric heating device 5 , an internal combustion engine 6 , an external combustion engine 7 , a wound plate heat exchanger 8 , a generator 9 and a water pump 19 .

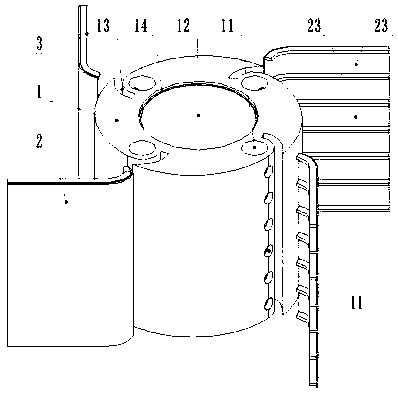

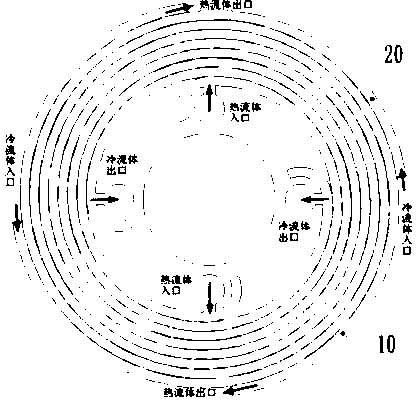

[0042] The wound plate heat exchanger 8, such as figure 2 As shown in the figure, it includes a core body 1, a metal plate 2, a support bar 3, a hot fluid channel 10, a cold fluid channel 20, and a rectangular flow channel 23. The core body 1 is processed with a core body flow channel 11 and a core cavity 12. , fixed groove 13, groove 14, the core flow channel 11 is formed by a round hole with a closed bottom processed on the upper end surface of the core body 1 and a row of round holes communicating with the round hole, and the core cavity 12 is formed on the core body The hole through which the end surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com