Beta-carotene emulsion and preparation method thereof

A technology of carotene and emulsion, which is applied in the direction of food ingredients as antioxidants, the function of food ingredients, and fat-containing food ingredients, etc., to achieve the effects of being easy to dissolve in water, avoiding peculiar smell, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

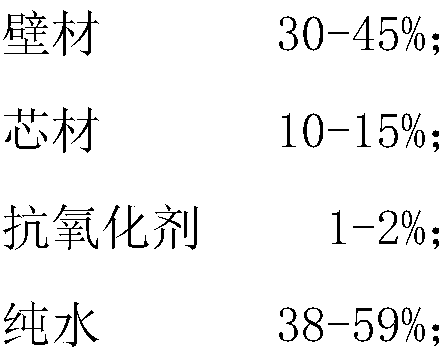

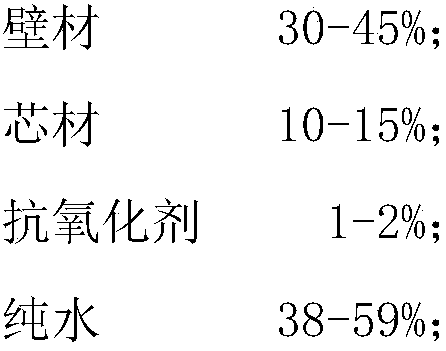

Method used

Image

Examples

Embodiment 1

[0034] 1) Preparation of emulsified phase: Weigh 10 kg of modified phospholipids, 10 kg of glycerin, 10 kg of sucrose, and 0.75 kg of sodium ascorbate, dissolve them in 59 kg of pure water at 65°C, stir, and keep warm for 25 minutes.

[0035] 2) Preparation of oil phase: Weigh 1.2kg of β-carotene, 8.8kg of soybean oil, and 0.25kg of vitamin E, heat to 140°C, keep warm for 20min, and then perform microscopic inspection, and proceed to the next step after no crystals are found.

[0036] 3) Slowly pour the oil phase prepared in step 2 into the emulsified phase prepared in step 1, stir for 2 minutes, and then cut with a shear for 2 minutes to fully disperse the oil phase in the emulsified phase.

[0037] 4) Homogenize the sheared emulsion once with a homogenizer, the homogenization pressure is 20Mpa for the second stage, and 3Mpa for the first stage.

[0038] 5) After the homogenized emulsion is irradiated by γ-rays, a finished emulsion with a content of β-carotene of 1% is obtain...

Embodiment 2

[0040] 1) Preparation of emulsified phase: Weigh 30 kg of modified phospholipids, 10 kg of glycerol, 5 kg of sucrose, and 0.5 kg of sodium ascorbate, dissolve them in 38 kg of pure water at 70°C, stir, and keep warm for 40 min.

[0041] 2) Preparation of the oil phase: Weigh 6kg of β-carotene, 9kg of sunflower oil, and 1.5kg of TBHQ, heat to 160°C, keep warm for 5min, and then perform the next step after microscopic inspection.

[0042] 3) Slowly pour the oil phase prepared in step 2 into the emulsified phase prepared in step 1, stir for 3 minutes, and then cut with a shear for 5 minutes to fully disperse the oil phase in the emulsified phase.

[0043] 4) Homogenize the sheared emulsion 3 times with a homogenizer, the homogenization pressure is 40Mpa for the second stage and 5Mpa for the first stage.

[0044] 5) After the homogenized emulsion is subjected to ultra-high temperature instantaneous sterilization at 127° C. for 8 seconds, a finished emulsion with a content of β-car...

Embodiment 3

[0046] 1) Preparation of emulsified phase: Weigh 20kg of modified phospholipids, 7kg of glycerin, 10kg of sucrose, and 0.75kg of sodium ascorbate, dissolve in 48.5kg of pure water at 68°C, stir, and keep warm for 32min.

[0047] 2) Oil phase preparation: Weigh 3.2kg of β-carotene, 9.8kg of peanut oil, and 0.75kg of BHT, heat to 150°C, keep warm for 10min, and then perform microscope inspection, and proceed to the next step after no crystals are found.

[0048] 3) Slowly pour the oil phase prepared in step 2 into the emulsified phase prepared in step 1, stir for 3 minutes, and then cut with a shear for 4 minutes to fully disperse the oil phase in the emulsified phase.

[0049] 4) Homogenize the sheared emulsion twice with a homogenizer, the homogenization pressure is 30Mpa for the second stage and 4Mpa for the first stage.

[0050] 5) After the homogenized emulsion is sterilized by gamma ray irradiation, a finished emulsion product with a content of β-carotene of 3% is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com