A kind of preparation method and application of silver-zinc oxide composite nanoparticles

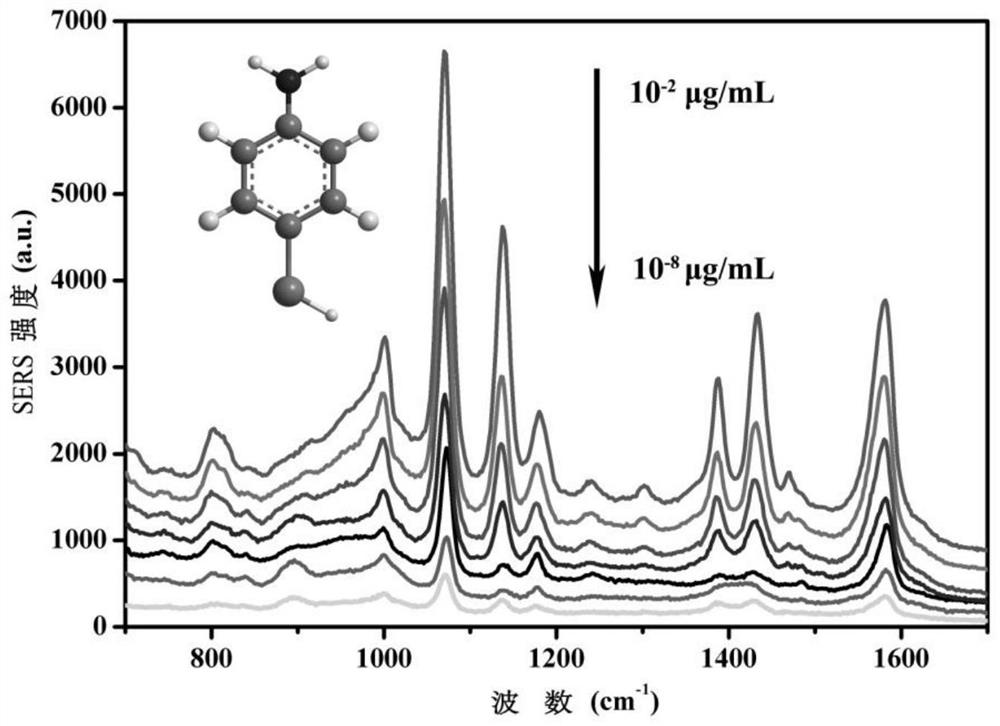

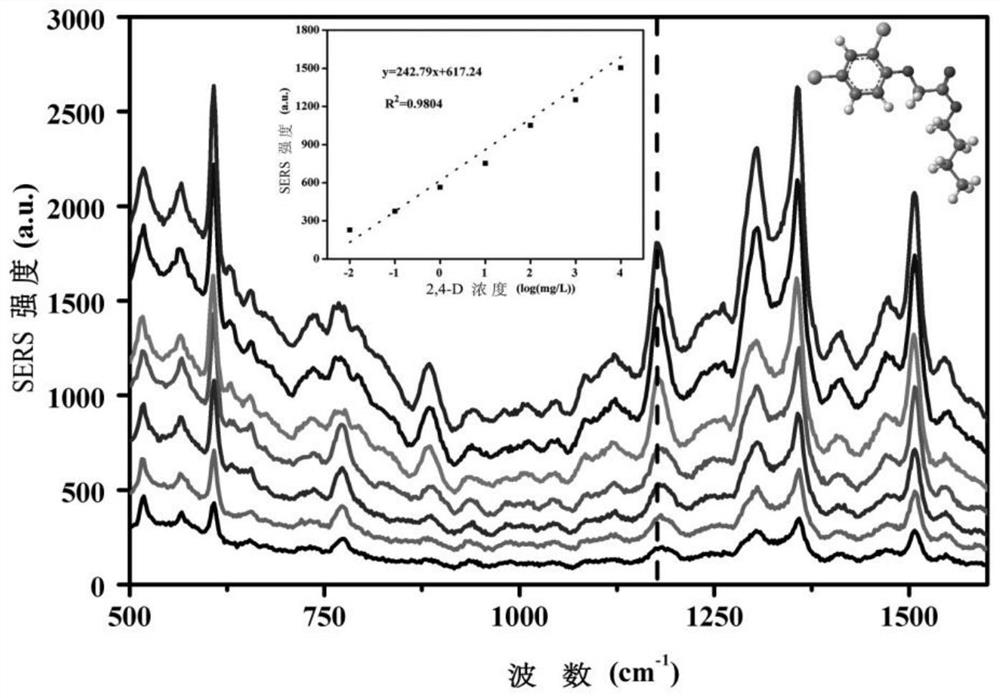

A composite nanoparticle and zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of undiscovered synthesis process, high reaction temperature surfactant, etc., and achieve strong Raman scattering enhancement effect, Raman spectrum intensity enhancement, effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

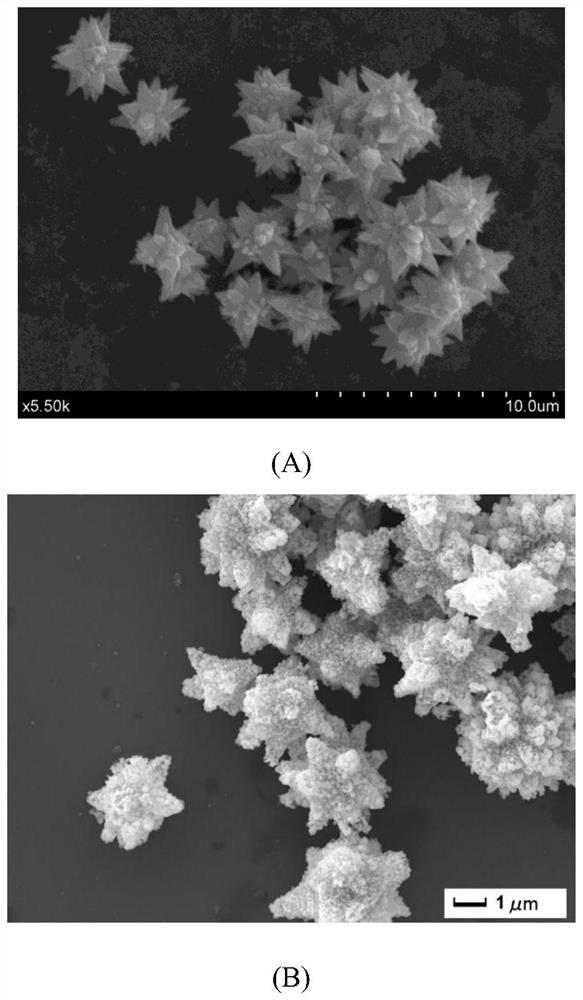

Embodiment 1

[0033]Prepare 200mL of zinc nitrate hexahydrate solution with a concentration of 0.006g / mL, preheat to 40°C in a magnetic stirring oil bath and keep stirring at a speed of 200rpm for 10min; then add 1.5mL of ammonia water with a concentration of 28wt% to the solution, and Set the temperature to 50°C and keep the rotation speed of 200rpm for 10h; after the reaction, cool the white turbid solution to room temperature, then centrifuge at 8000rpm for 15min, discard the supernatant, and deionize the collected white precipitate with deionized water. Washing; continue to centrifuge under the same conditions, discard the supernatant, and wash the white precipitate with absolute ethanol, centrifuge again at 8000rpm for 15min, wash with deionized water and collect the white precipitate after centrifugation, which is pure zinc oxide Particles are dried at 50° C. for 8 hours to finally obtain nanometer zinc oxide particles.

[0034] Take 0.3g of the above-mentioned nano-zinc oxide particl...

Embodiment 2

[0037] Prepare 200mL of zinc nitrate hexahydrate solution with a concentration of 0.004g / mL, preheat to 40°C in a magnetically stirred water bath and keep stirring at 200rpm for 10min; then add 0.5mL of 25wt% ammonia water to the solution, and set the temperature to at 40°C, keep the rotation speed of 200rpm for 16h; after the reaction, cool the white turbid solution to room temperature, then centrifuge at 8000rpm for 15min, discard the supernatant, and wash the collected white precipitate with deionized water; Continue to centrifuge under the same conditions, discard the supernatant, and use absolute ethanol to wash the white precipitate, centrifuge again at 8000rpm for 15 minutes, use deionized water to wash and collect the white precipitate after centrifugation, which is pure zinc oxide particles. The precipitate was dried at 50° C. for 8 hours to finally obtain nanometer zinc oxide particles.

[0038] Take 0.2g of the above-mentioned nano-zinc oxide particles, 0.5g PVP K60...

Embodiment 3

[0040] Prepare 200mL of zinc nitrate hexahydrate solution with a concentration of 0.01g / mL, preheat to 40°C in a magnetically stirred water bath and keep stirring at 200rpm for 10min; then add 3mL of 28wt% ammonia water to the solution and set the temperature to 45°C, Keep the speed of reaction at 200rpm for 18h; after the reaction, cool the obtained white turbid liquid to room temperature, then centrifuge at 8000rpm for 15min, discard the supernatant, and wash the collected white precipitate with deionized water; continue centrifugation under the same conditions , discard the supernatant, and wash the white precipitate with absolute ethanol, centrifuge again at 8000rpm for 15min, wash with deionized water and collect the white precipitate after centrifugation, which is pure zinc oxide particles. The precipitate was dried for 8 hours to finally obtain nanometer zinc oxide particles.

[0041] Take 0.5 g of the above-mentioned nano-zinc oxide particles, 2.5 g of PVP (K30:K90=1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com