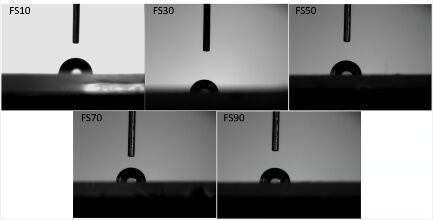

Novel method for preparing hydrophobic self-healing hyperelastic polyurethane elastomer

A polyurethane elastic and superelastic technology, applied in the field of polyurethane, can solve the problems of complicated steps, high cost, slow material self-repairing process, etc., and achieve the effects of avoiding complicated steps, mild conditions and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

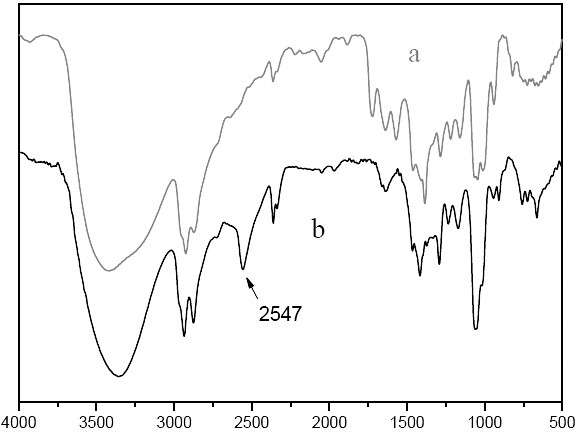

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of 2,2'-dithiodiethanol: take a 30% hydrogen peroxide solution and β-mercaptoethanol with a molar ratio of 1.1:1 to prepare a sodium hydroxide solution with a pH of 9 to 11, and mix β -Mercaptoethanol was added to the sodium hydroxide solution, and 30% hydrogen peroxide solution was added dropwise with stirring at 25°C. After the dropwise addition, the two were mixed evenly, and the reaction was stirred at 300 rpm in a three-necked flask for 2.5 hours. After the reaction was completed, the synthesized organic product was extracted with ethyl acetate and repeated 4 times. The obtained organic layer was subjected to rotary evaporation treatment with a rotary evaporator. The ethyl acetate extractant was removed, and finally it was placed in a vacuum oven and dried at 50 °C for 12 h to remove trace water.

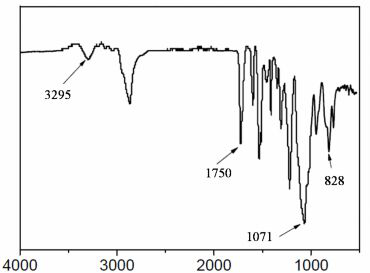

[0027] (2) Preparation of twin-type chain extender: place bisphenol AF in a vacuum oven at 110 ° C to dry and remove water for 8 h, take bisphenol AF and ...

Embodiment 2

[0030] (1) Synthesis of dithiodiphenol: take a 30% hydrogen peroxide solution and 2-hydroxy thiophenol with a molar ratio of 1.1:1 to prepare a sodium hydroxide solution with a pH of 9 to 11. The thiophenol was added to the sodium hydroxide solution, and 30% hydrogen peroxide solution was added dropwise with stirring at 25°C. After the dropwise addition, the two were mixed evenly, and the reaction was stirred at 300 rpm in a three-necked flask for 2.5 hours. After the reaction was completed, the synthesized organic product was extracted with ethyl acetate and repeated 4 times. The obtained organic layer was subjected to rotary evaporation treatment with a rotary evaporator. The ethyl acetate extractant was removed, and finally it was placed in a vacuum oven and dried at 50 °C for 12 h to remove trace water.

[0031] (2) Preparation of twin-type chain extender: 3-(N,N-dihydroxyethyl) hexafluorobutyl methacrylate was placed in a vacuum oven at 50 ° C to dry and remove water for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com