Hierarchical porous zeolite imidazate skeletal material, and preparation method thereof

A technology of zeolite imidazolate and framework materials, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., and can solve the problems of easy collapse of mesopores, long reaction time, and non-environmental protection , to achieve good catalytic activity, mild conditions, and short time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a hierarchical porous zeolite imidazolate framework material, comprising the following steps:

[0034] (1) Add 0.44g Zn(NO 3 ) 2 ·6H 2 O and 0.13g Sodium Dodecyl Sulfate (SDS), stirred at 60°C until the solid was dissolved to obtain a clear and transparent homogeneous solution;

[0035] (2) Add 0.49g of 2-methylimidazole (2-Mim) to the homogeneous solution, and stir at 60°C for 30min to obtain a suspension;

[0036] (3) Centrifuge the suspension, wash with 50% ethanol aqueous solution and absolute ethanol, and dry at 110° C. for 12 hours to obtain the zeolite imidazolate framework material (ZIF8). Table 1 shows the structural characterization test data of the zeolite-like imidazolate framework material prepared in this example.

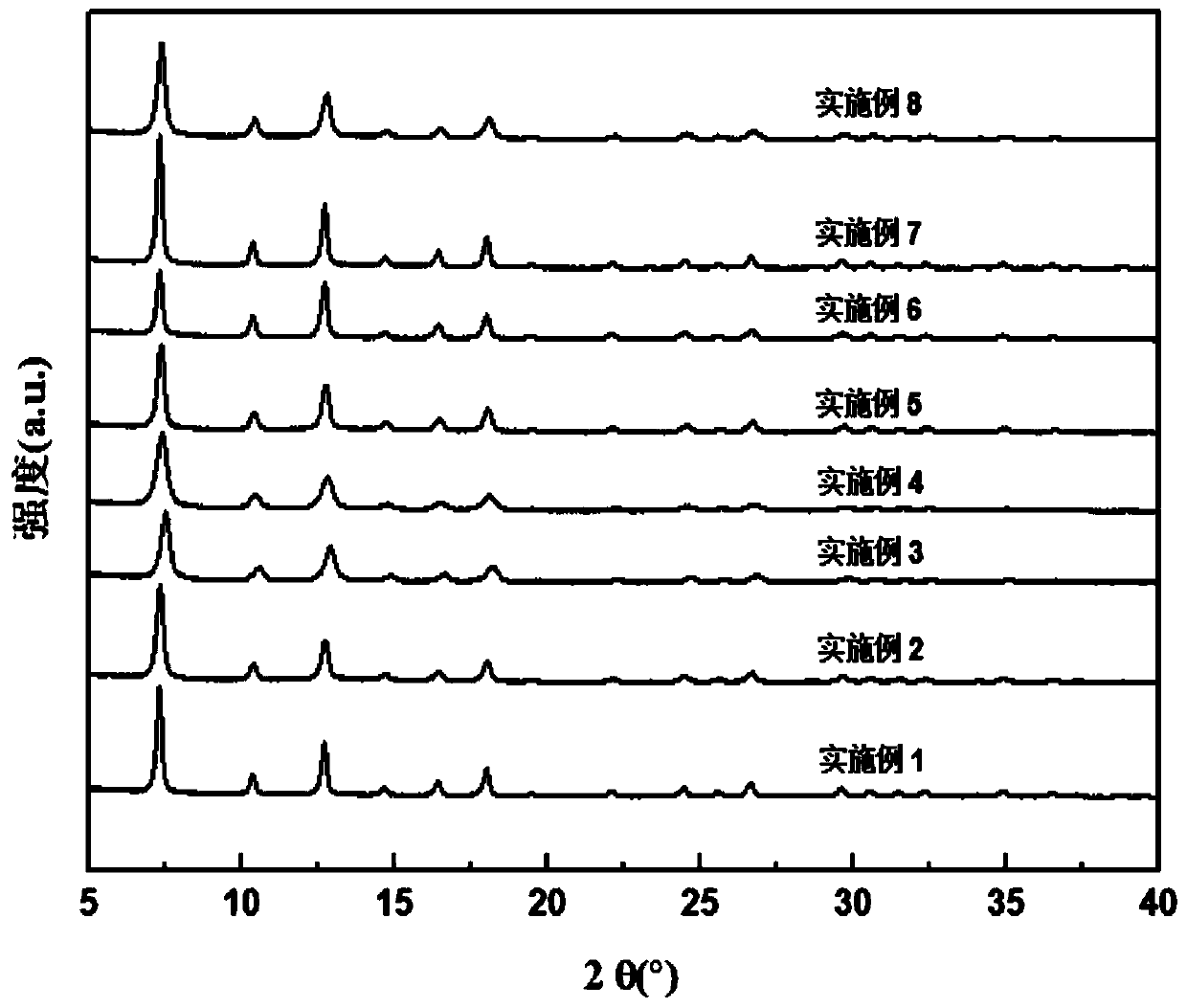

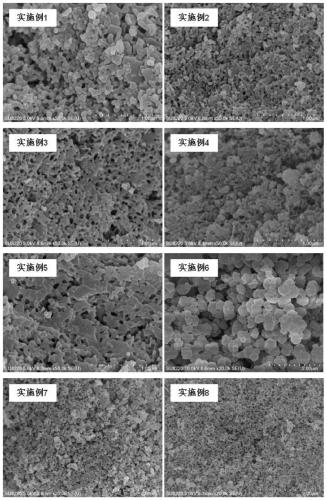

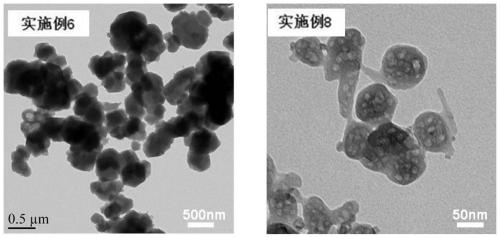

[0037] The X-ray diffraction pattern of the hierarchically porous zeolite imidazolate framework material (ZIF-8) prepared in Example 1 is as follows figure 1 As shown, the scanning electron microscope image is shown...

Embodiment 2

[0039] A preparation method of a hierarchical porous zeolite imidazolate framework material, comprising the following steps:

[0040] (1) With 4.75g deep eutectic solvent (ChCl / urea-DES, the molar ratio of choline chloride and urea is 1:2) and 0.25g deionized water, stir and mix evenly, obtain mixed solvent;

[0041] (2) Add 0.44g Zn(NO 3 ) 2 ·6H 2 O and 0.13g Sodium Dodecyl Sulfate (SDS), stirred at 60°C until the solid was dissolved to obtain a clear and transparent homogeneous solution;

[0042] (3) Add 0.49g of 2-methylimidazole (2-Mim) to the homogeneous solution and stir at 60°C for 30min to obtain a suspension;

[0043] (4) Centrifuge the suspension, wash with 50% ethanol aqueous solution and absolute ethanol, and dry at 110° C. for 12 hours to obtain the zeolite imidazolate framework material. Table 1 shows the structural characterization test data of the zeolite-like imidazolate framework material prepared in this example.

[0044] The X-ray diffraction pattern o...

Embodiment 3

[0046] A preparation method of a hierarchical porous zeolite imidazolate framework material, comprising the following steps:

[0047] (1) With 4.25g deep eutectic solvent (ChCl / urea-DES, the molar ratio of choline chloride and urea is 1:2) and 0.75g deionized water, stir and mix evenly, obtain mixed solvent;

[0048] (2) Add 0.44g Zn(NO 3 ) 2 ·6H 2 O and 0.13g Sodium Dodecyl Sulfate (SDS), stirred at 60°C until the solid was dissolved to obtain a clear and transparent homogeneous solution;

[0049] (3) Add 0.49g of 2-methylimidazole (2-Mim) to the homogeneous solution and stir at 60°C for 30min to obtain a suspension;

[0050](4) Centrifuge the suspension, wash with 50% ethanol aqueous solution and absolute ethanol, and dry at 110° C. for 12 hours to obtain the zeolite imidazolate framework material. Table 1 shows the structural characterization test data of the zeolite-like imidazolate framework material prepared in this example.

[0051] The X-ray diffraction pattern of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com