Feeding linage system for bagasse furnace of cane sugar factory

A linkage system and sugar cane technology, applied in the field of bagasse furnace, can solve the problems of manual manual control of control mode, uneven feeding of bagasse furnace, low combustion efficiency of bagasse furnace, etc. The effect of taking up less space in the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

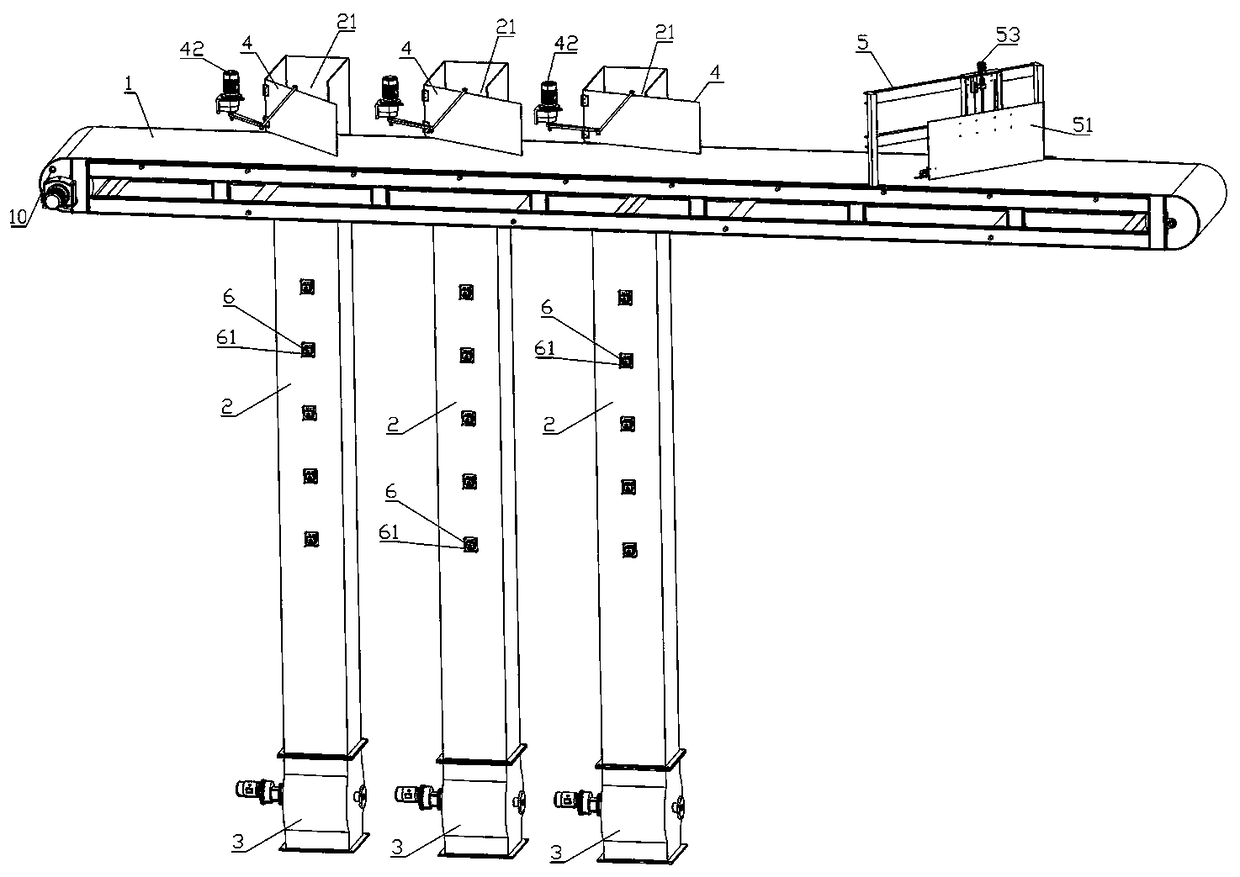

[0031] refer to Figure 1 to Figure 6 , a bagasse furnace feeding linkage system in a sugarcane sugar factory, which includes a feeding conveyor belt 1, a feeding hopper 2 and a feeder 3.

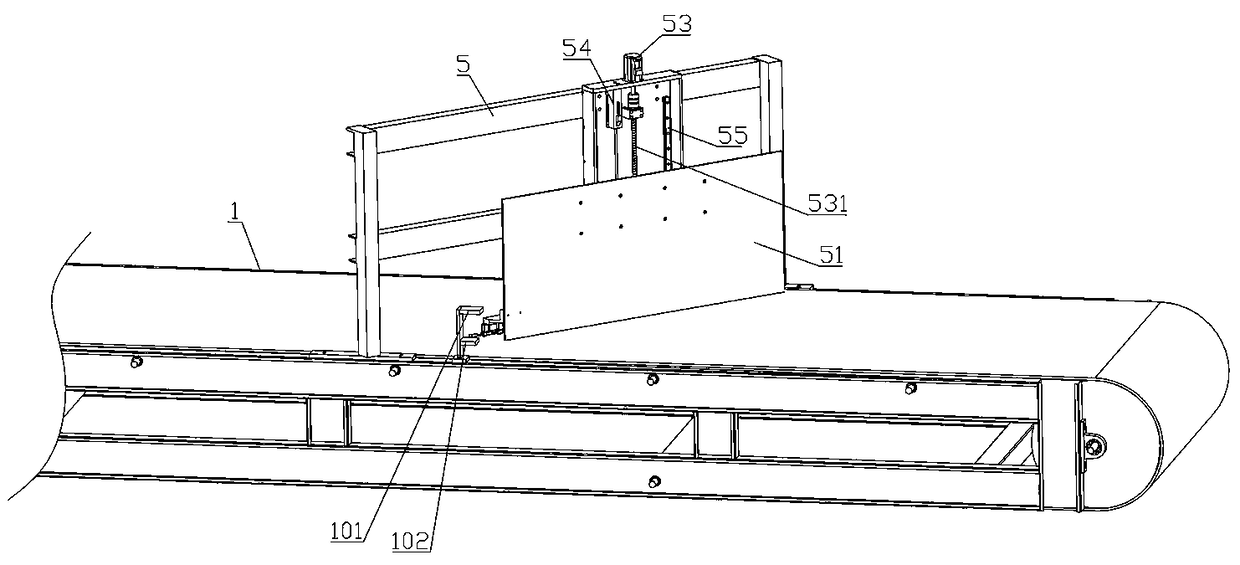

[0032] The feeding conveyor belt 1 is arranged horizontally, and a conveying speed sensor 10 is installed on its driving mechanism for sensing and outputting a conveying belt speed signal.

[0033] A plurality of feeding hoppers 2 are vertically arranged on the side of the feeding conveyor belt 1. The feeding hoppers 2 are cylindrical shells. The bottom end has a discharge port.

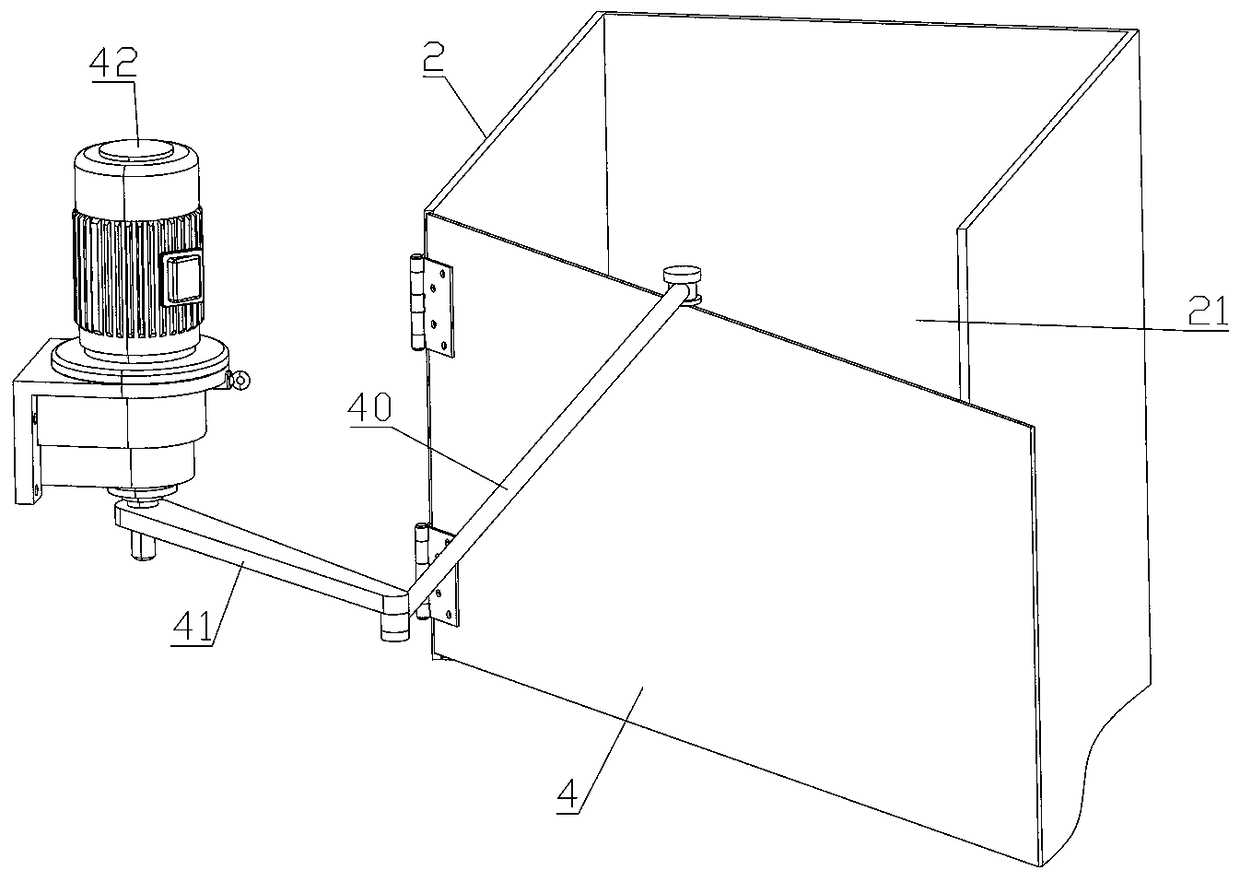

[0034] combined reference figure 1 and figure 2 , near the feed port 21 of each feeding hopper 2, a pusher device is installed, and the pusher device includes a feed pusher 4, a connecting rod 41 and a pusher motor 42, and the feeder pusher 4 is vertically arranged at The top of the feeding conveyor belt 1 is connected to the feeding port 21 of the feeding hopper 2 with a living hinge, the bottom end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com