High-concentration, degradation-resistant chemical synthesis pharmaceutical wastewater treatment method and system

A chemical synthesis and treatment method technology, applied in the field of wastewater treatment, can solve the problems of strong biological toxicity, substandard water quality, complex components, etc., and achieve the effects of poor impact load resistance, COD degradation, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 High concentration, refractory chemical synthesis pharmaceutical wastewater treatment

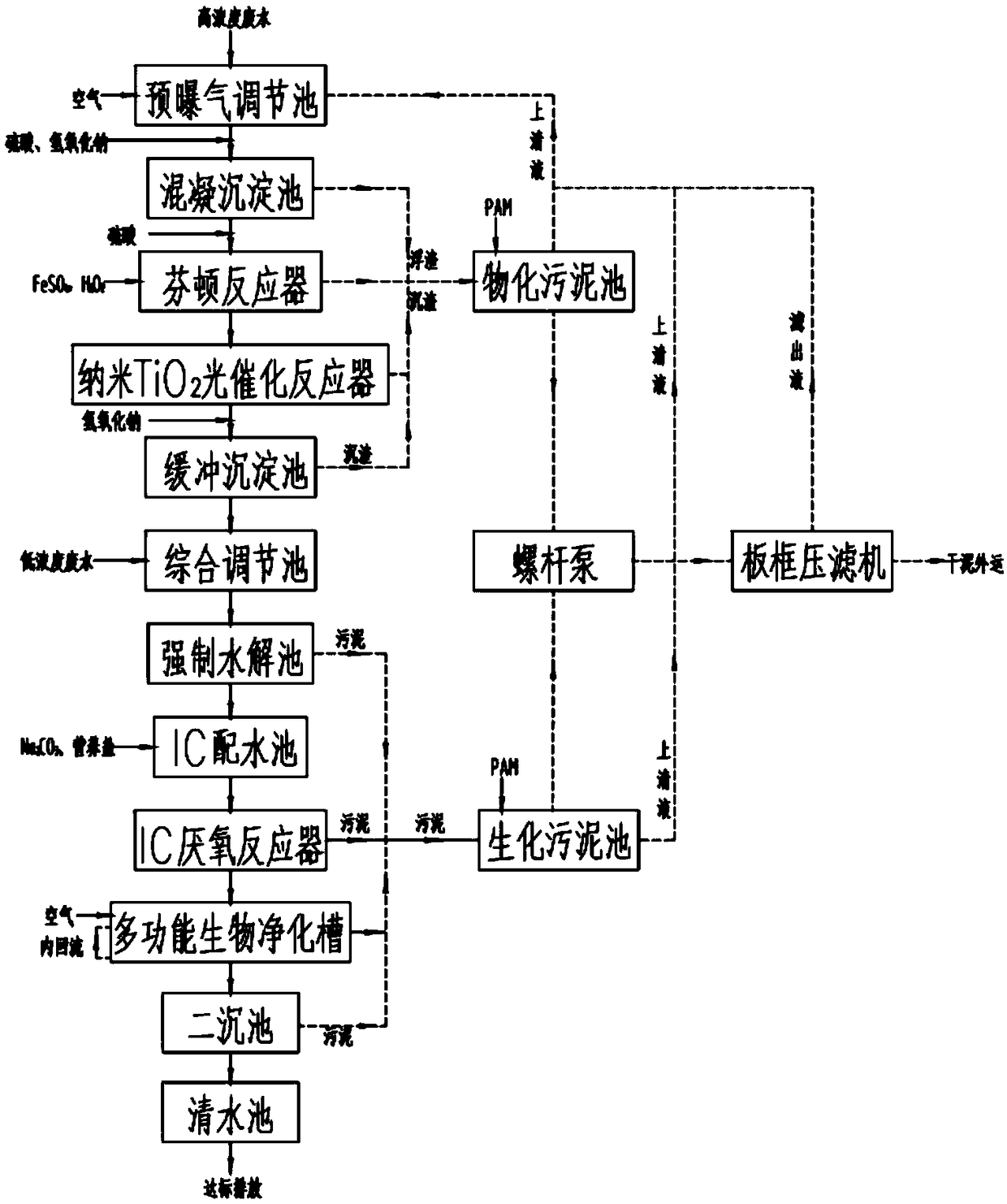

[0039] For the treatment of high-concentration, refractory chemical synthesis and pharmaceutical wastewater, follow the steps below, and the process flow chart is as follows: figure 1 Shown:

[0040] (1) Since the wastewater discharge cycle of the pharmaceutical factory is uncertain, a large amount of high-concentration wastewater is discharged during the pilot test. The high-concentration pharmaceutical wastewater is input into the pre-aeration regulating tank, and the perforated tube is used to aerate and stir in the tank to make the water quality more uniform. The hydraulic retention time of the pre-aeration regulating tank is 4 days. The pre-aeration system adopts ABS material pipes, and the left and right opening angles are 30°. The fan type is selected according to air:water=10:1.

[0041] (2) Lift the wastewater in the pre-aeration adjustment tank to the coagulatio...

Embodiment 2

[0055] The specific treatment object of the present invention is pharmaceutical intermediate chemical synthesis pharmaceutical wastewater, water volume 500m 3 / d, of which high concentration wastewater 60m 3 / d, low concentration wastewater 440m 3 / d, the effluent is required to meet the standards in Table 2 of the "Discharge Standards for Water Pollutants of Chemical Synthesis Pharmaceutical Industry" (GB21904-2008), and the specific water quality is shown in Table 1:

[0056] Table 1

[0057]

[0058] According to the method of Example 1, the high-concentration wastewater and low-concentration wastewater in Table 1 are treated, wherein the high-concentration wastewater physicochemical system adopts flocculation precipitation + Fenton reactor + nano TiO 2 Photocatalytic. Use flocculation and sedimentation to remove suspended matter, and then enter the Fenton reactor + nano-TiO 2 Photocatalysis produces OH, destroys the structure and stability of molecules, opens rings ...

Embodiment 3

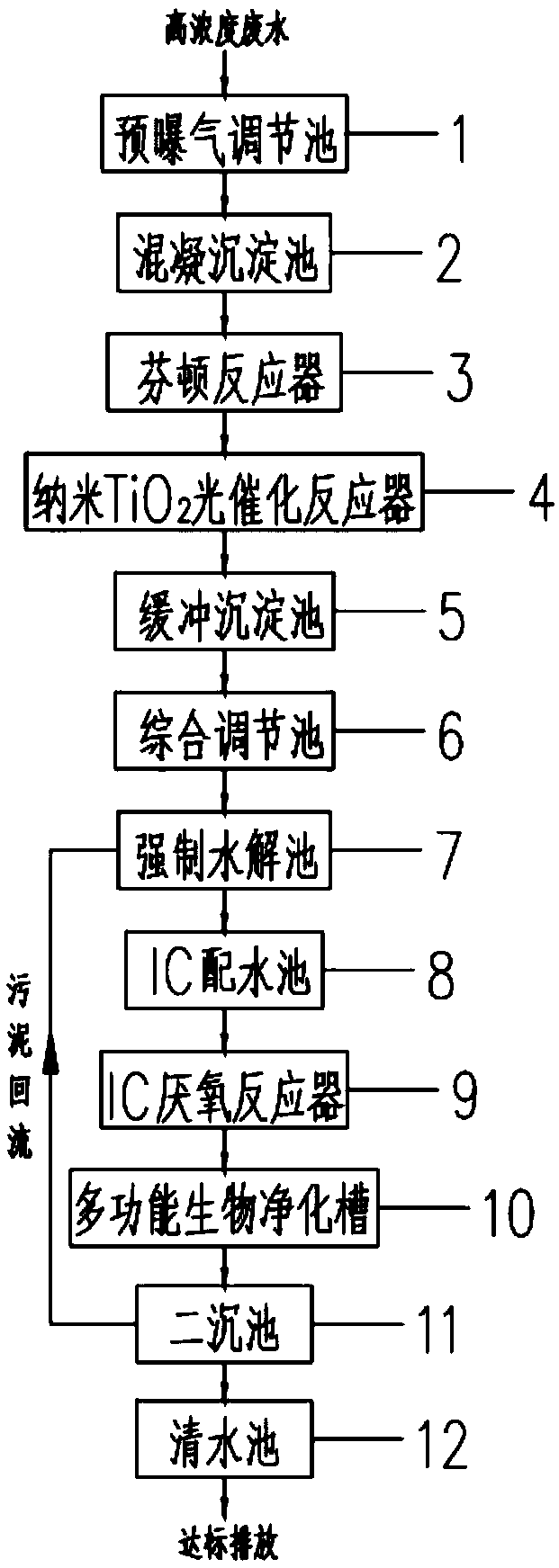

[0061] Example 3 High-concentration, refractory chemical synthesis pharmaceutical wastewater treatment system

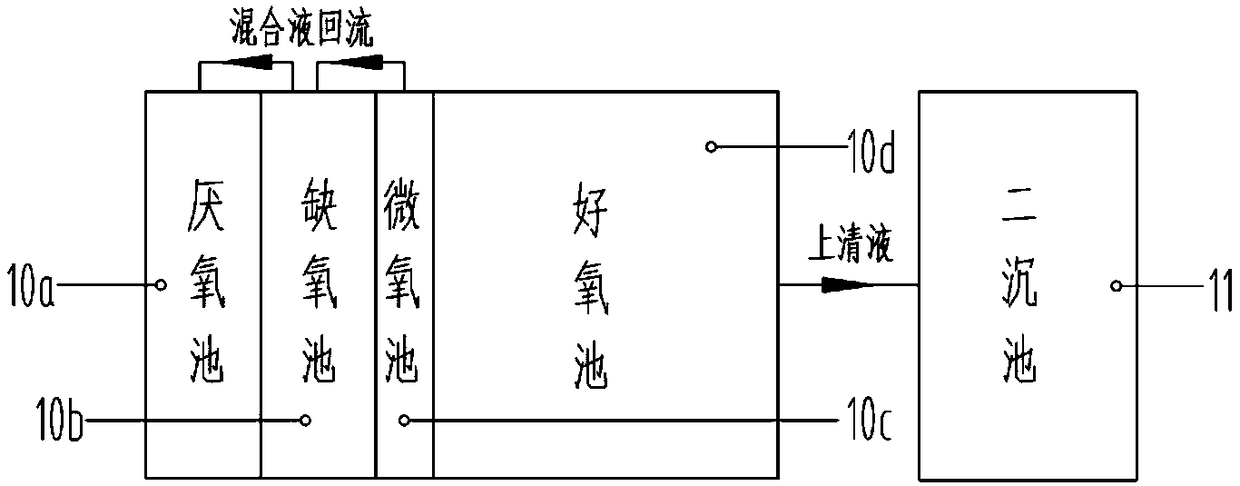

[0062] A high-concentration, refractory chemical synthesis pharmaceutical wastewater treatment system used in the treatment methods of Examples 1 and 2, mainly composed of the following components: a pre-aeration adjustment tank 1 and a coagulation sedimentation tank 2 connected in sequence through pipelines , Fenton reactor 3, nano-TiO 2 Photocatalytic reactor 4, buffer sedimentation tank 5, comprehensive adjustment tank 6, forced hydrolysis tank 7, IC water distribution tank 8, IC anaerobic reactor 9, multifunctional biological purification tank 10, secondary sedimentation tank 11 and clear water tank 12. The forced hydrolysis tank 7 is to add a pulse water distribution system to the conventional hydrolysis acidification tank. The pulse water distribution system is composed of a high-efficiency pulse water distribution tank and a spiral umbrella water distributor; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com