Waste water nitrogen and phosphorus removal apparatus and waste water treatment method

A technology for denitrification, dephosphorization, and wastewater, which is applied in water/sewage treatment, chemical instruments and methods, and multi-stage water/sewage treatment. In order to achieve high phosphate removal rate, improve sewage purification efficiency, and reduce pollution exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

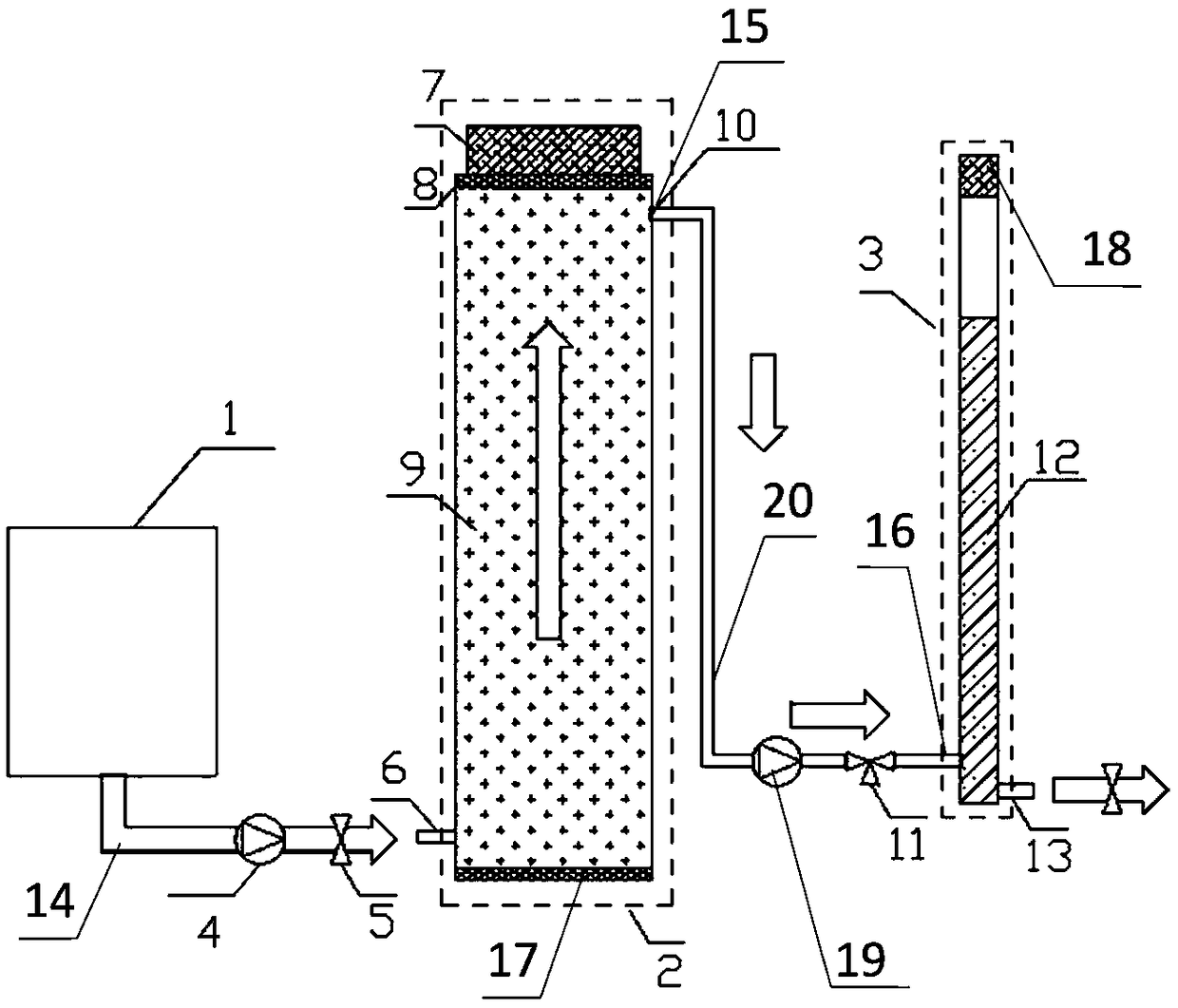

[0045] This embodiment 1 adopts such as figure 1 The shown denitrification and phosphorus removal device treats the drainage of an agricultural floor tile, which includes a sewage pool 1, a denitrification column 2, a phosphorus filter column 3, a water inlet pipe 14 and a connecting pipe 20; the lower part of the denitrification column 2 has a first-stage inlet The water outlet 6 has a first-level water outlet 15 on the top; a second-level water inlet 16 and a second-level water outlet 13 are respectively arranged on the opposite sides of the lower part of the phosphorus filter column 3; The primary water inlet 6 is connected; the secondary water inlet 16 at the bottom of the phosphorus filter column 3 is connected with the primary water outlet 15 at the top of the denitrification column 2 through a connecting pipe 20; the water inlet pipe 14 is provided with a water inlet peristaltic pump 4 and The valve switch 5 ; the connecting pipe 20 is provided with a peristaltic pump 1...

Embodiment 2

[0058] This embodiment is further improved on the basis of Embodiment 1.

[0059] The primary water outlet 15 at the top of the denitrification column 2 is provided with a stainless steel filter screen 10 with a pore size of 25 mesh. The sawdust 9 filled in the denitrification column 2 has a particle size of 4-8mm, and is formed by soaking in 0.1mol / L NaOH for 12 hours, washing with water to neutrality, and air-drying; the filling height of the sawdust 9 accounts for 90% of the height of the denitrification column 2 %, the total porosity filled is 68%.

[0060] The particle size of the acid mine drainage residue 12 filled in the phosphorus filter column 3 is 0.6-4.0 cm, the filling height accounts for 80% of the height of the phosphorus filter column 3 , and the filling total porosity is 60%.

[0061] The specific steps of using the device of this embodiment to remove nitrogen and phosphorus from wastewater are as follows:

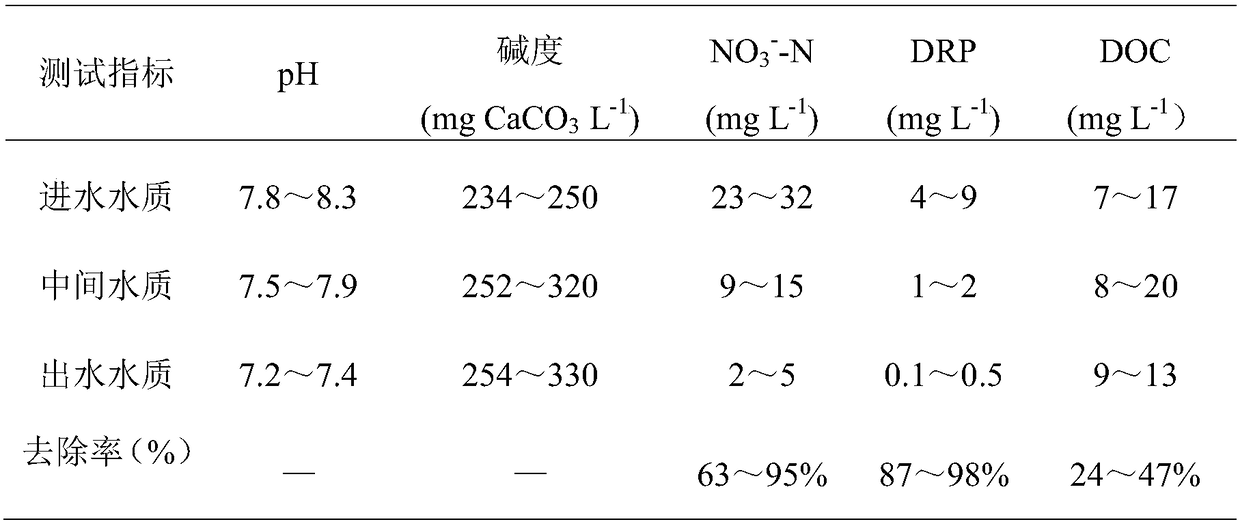

[0062] A. Build above-mentioned denitrification an...

Embodiment 3

[0070] This embodiment is further improved on the basis of embodiment 2.

[0071] The wood chips 9 filled in the denitrification column 2 have a particle size of 5-7mm, and are soaked in 0.3mol / L NaOH for 36 hours, washed with water until neutral, and air-dried; the filling height of the wood chips 9 accounts for 95% of the height of the denitrification column 2. %, the total porosity is 78%.

[0072] The acid mine drainage residue 12 filled in the phosphorus filter column 3 has a particle size of 1.6 to 3.4 cm, the filling height accounts for 85% of the height of the phosphorus filter column 3, and the total porosity of the filling is 80%;

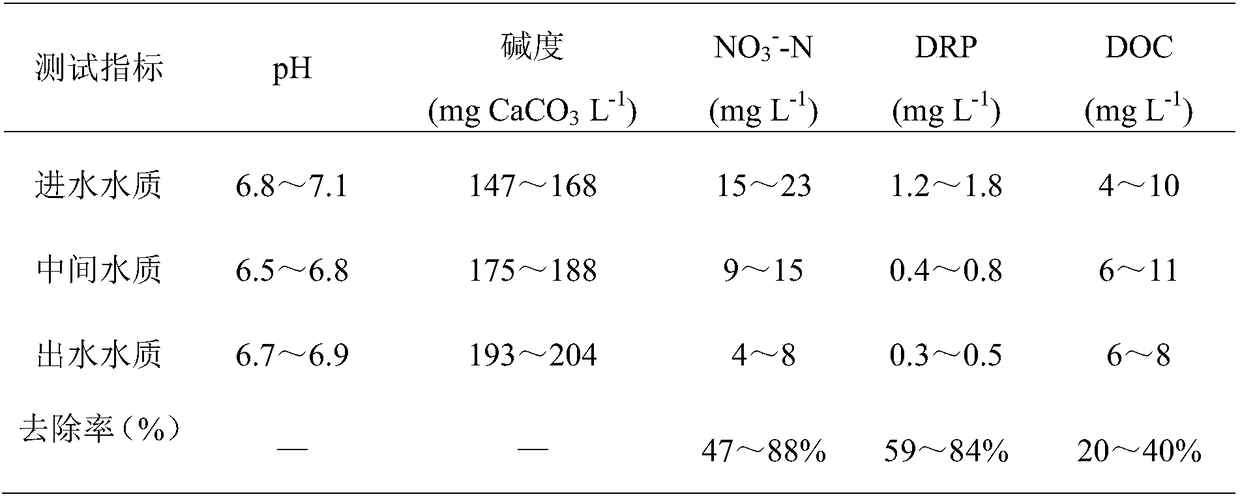

[0073] The specific steps of using the device of this embodiment to remove nitrogen and phosphorus from wastewater are as follows:

[0074] A. Build above-mentioned denitrification and dephosphorization device, and under the hydraulic retention time is 7h, sawdust 9 is carried out 2 times of leaching; Before experiment, acid mine drainag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com