Preparation method of low-solubility phenolic resin for oilfield enhanced oil recovery

A low-solubility, phenolic resin technology, which is applied in the field of preparation of low-solubility phenolic resins for enhanced oil recovery in oil fields, can solve the problems of good water solubility of products, difficulty in forming molecular aggregates, and reduction of solid content of products, etc., to achieve high effective content , good storage stability, the effect of promoting addition reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

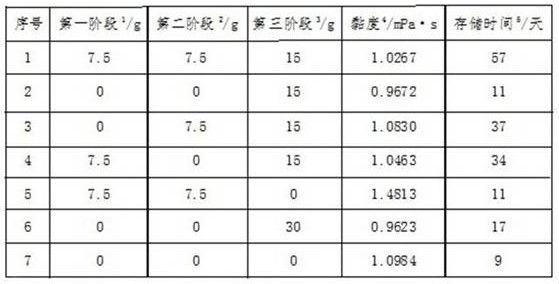

Examples

Embodiment 1

[0018] Prepare raw materials: phenol, 37% formaldehyde solution, sodium hydroxide, deionized water.

[0019] Firstly, phenol is sealed and melted at 50°C. After the phenol is completely melted, add 47g of phenol into a 500ml four-necked bottle, and then add 15g of sodium hydroxide solution (mass fraction 20%) into the four-necked bottle. Install an electric stirrer, a reflux condenser, a thermometer and a constant pressure dropping funnel into the four-necked bottle and heat it in a water bath to keep the temperature in the bottle at 70-80°C. Add 81g of formaldehyde dropwise to the four-necked bottle, stir and control the drop rate of formaldehyde, and react for 30-40 minutes. Adjust the temperature of the water bath so that the temperature of the reactants in the bottle is 90°C. After 120 minutes of reaction, add 27g of water and 7.5g of NaOH (mass fraction 40%) to make the effective content of low-solubility phenolic resin reach 40%, and continue the reaction for 30-40 minut...

Embodiment 2

[0021] Prepare raw materials: phenol, 37% formaldehyde solution, sodium hydroxide, deionized water.

[0022] Firstly, phenol is sealed and melted at 50°C. After the phenol is completely melted, add 47g of phenol into a 500ml four-necked bottle, and then add 15g of sodium hydroxide solution (mass fraction 20%) into the four-necked bottle. Install an electric stirrer, a reflux condenser, a thermometer and a constant pressure dropping funnel into the four-necked bottle and heat it in a water bath to keep the temperature in the bottle at 70-80°C. Add 81g of formaldehyde dropwise to the four-necked bottle, stir and control the drop rate of formaldehyde, and react for 30-40 minutes. Adjust the temperature of the water bath so that the temperature of the reactants in the bottle is 90°C. After 120 minutes of reaction, add 34.5g of water to make the effective content of the low-solubility phenolic resin reach 40%, and continue the reaction for 30-40 minutes; add 42.5g of water again to...

Embodiment 3

[0024] Prepare raw materials: phenol, 37% formaldehyde solution, sodium hydroxide, deionized water.

[0025] Firstly, phenol is sealed and melted at 50°C. After the phenol is completely melted, add 47g of phenol into a 500ml four-necked bottle, and then add 15g of sodium hydroxide solution (mass fraction 20%) into the four-necked bottle. Install an electric stirrer, a reflux condenser, a thermometer and a constant pressure dropping funnel into the four-necked bottle and heat it in a water bath to keep the temperature in the bottle at 70-80°C. Add 81g of formaldehyde dropwise to the four-necked bottle, stir and control the drop rate of formaldehyde, and react for 30-40 minutes. Adjust the temperature of the water bath so that the temperature of the reactants in the bottle is 90°C. After 120 minutes of reaction, add 34.5g of water to make the effective content of the low-solubility phenolic resin reach 40%, and continue the reaction for 30-40 minutes; add 35g of water and 7.5g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com