A kind of preparation method of high-strength mg-li-sn-zn ultralight alloy

A mg-li-sn-zn, ultra-light alloy technology, applied in the field of metal materials, can solve the problems of low strength and difficult to meet engineering applications, and achieve the effects of simple operation, promotion of aging precipitation, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

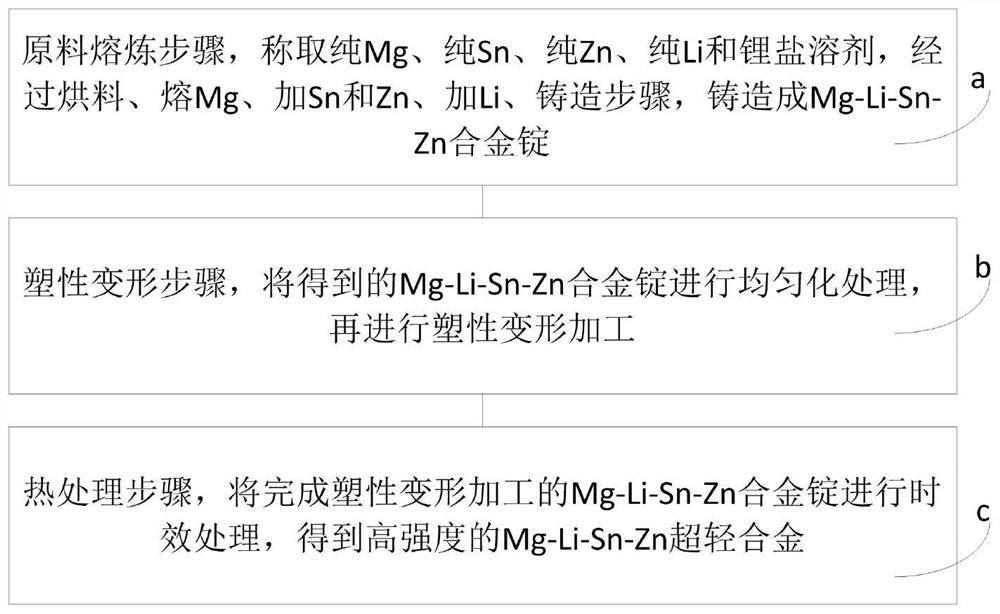

Method used

Image

Examples

Embodiment 1

[0045] The composition and mass percent of the high-strength Mg-Li-Sn-Zn ultra-light alloy are: 6wt% Li, 3wt% Sn, 0.5wt% Zn, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt%, the balance is Mg.

[0046] Raw material smelting steps:

[0047] i) Weigh pure Mg, pure Sn, pure Zn, and pure Li according to the above mass percentages, weigh lithium salt solvent according to 5% of the mass of the prepared alloy, and then preheat and dry all the above-mentioned raw materials at 180 ° C for more than 3 hours to obtain Dry pure Mg, pure Sn, pure Zn, pure Li and lithium salt solvent;

[0048] ii) putting the dried Mg and lithium salt solvent obtained in step i) into a crucible resistance furnace for heating and melting to obtain magnesium liquid;

[0049] iii) Heating the magnesium liquid obtained in step ii) to 740°C, then adding the dried pure Sn obtained in step i), heating until all of it melts into liquid metal, and after the temperature of the liqui...

Embodiment 2

[0056] The components and mass percentages of the high-strength Mg-Li-Sn-Zn ultralight alloy are: 8wt% Li, 4wt% Sn, 1wt% Zn, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02 wt%, the balance is Mg.

[0057] Raw material smelting steps:

[0058] i) Weigh pure Mg, pure Sn, pure Zn, and pure Li according to the above mass percentages, weigh lithium salt solvent according to 8% of the mass of the prepared alloy, and then preheat and dry all the above-mentioned raw materials at 200 ° C for more than 3 hours to obtain Dry pure Mg, pure Sn, pure Zn, pure Li and lithium salt solvent;

[0059] ii) putting the dried Mg and lithium salt solvent obtained in step i) into a crucible resistance furnace for heating and melting to obtain magnesium liquid;

[0060] iii) Heating the magnesium liquid obtained in step ii) to 720°C, then adding the dried pure Sn obtained in step i), heating until all of it melts into a metal liquid, and after the temperature of the me...

Embodiment 3

[0067] The composition and mass percent of the high-strength Mg-Li-Sn-Zn ultralight alloy are: 10wt% Li, 6wt% Sn, 1.5wt% Zn, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt%, the balance is Mg.

[0068] Raw material smelting steps:

[0069] i) Weigh pure Mg, pure Sn, pure Zn, and pure Li according to the above mass percentages, weigh lithium salt solvent according to 8% of the mass of the prepared alloy, and then preheat and dry all the above-mentioned raw materials at 250 ° C for more than 3 hours to obtain Dry pure Mg, pure Sn, pure Zn, pure Li and lithium salt solvent;

[0070] ii) putting the dried Mg and lithium salt solvent obtained in step i) into a crucible resistance furnace for heating and melting to obtain magnesium liquid;

[0071] iii) Heat the magnesium liquid obtained in step ii) to 700°C, then add the dried pure Sn obtained in step i), heat until all of it melts into a metal liquid, and after the temperature of the metal liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com